ZEISS ScanBox 5 系

复杂几何形状的在线检测

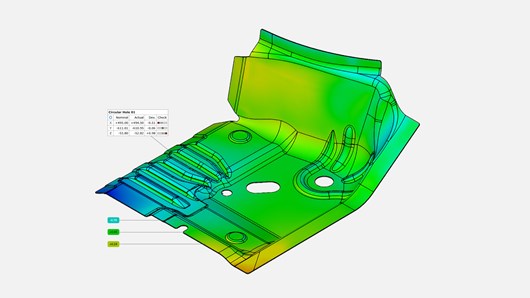

ZEISS ScanBox 5系是复杂零件自动化检测和数字化处理的一站式解决方案。这一强大的三维测量系统可在短时间内提供用于CAD比较的全域测量结果,可视化GD&T偏差,并加速生产、维护和维修过程。使用该系统可以快速获取特定的测量特征和几何形状,如表面和边缘点、孔或孔。

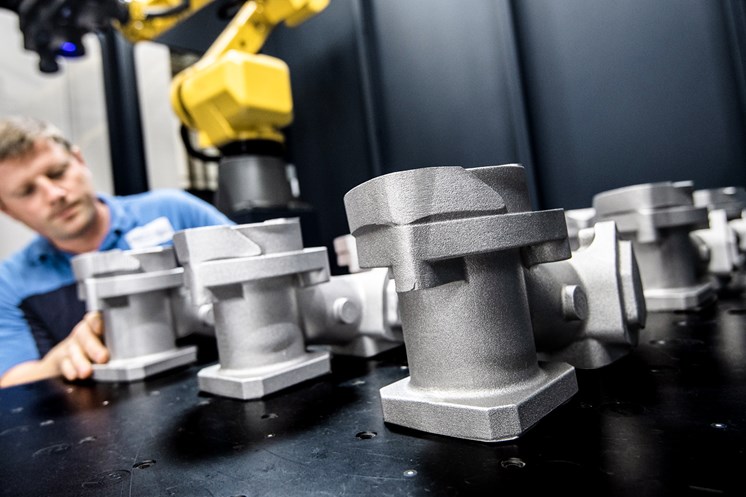

批量生产中的质量保证

ZEISS ScanBox 5系优化您的批量检测流程,并为生产过程中的质量控制提供支持。标准化、自动化流程可提高零件产量,减少废品。通过实时趋势分析,ZEISS ScanBox 5系确保工艺流程稳定,并对生产中出现的变化做出快速识别。

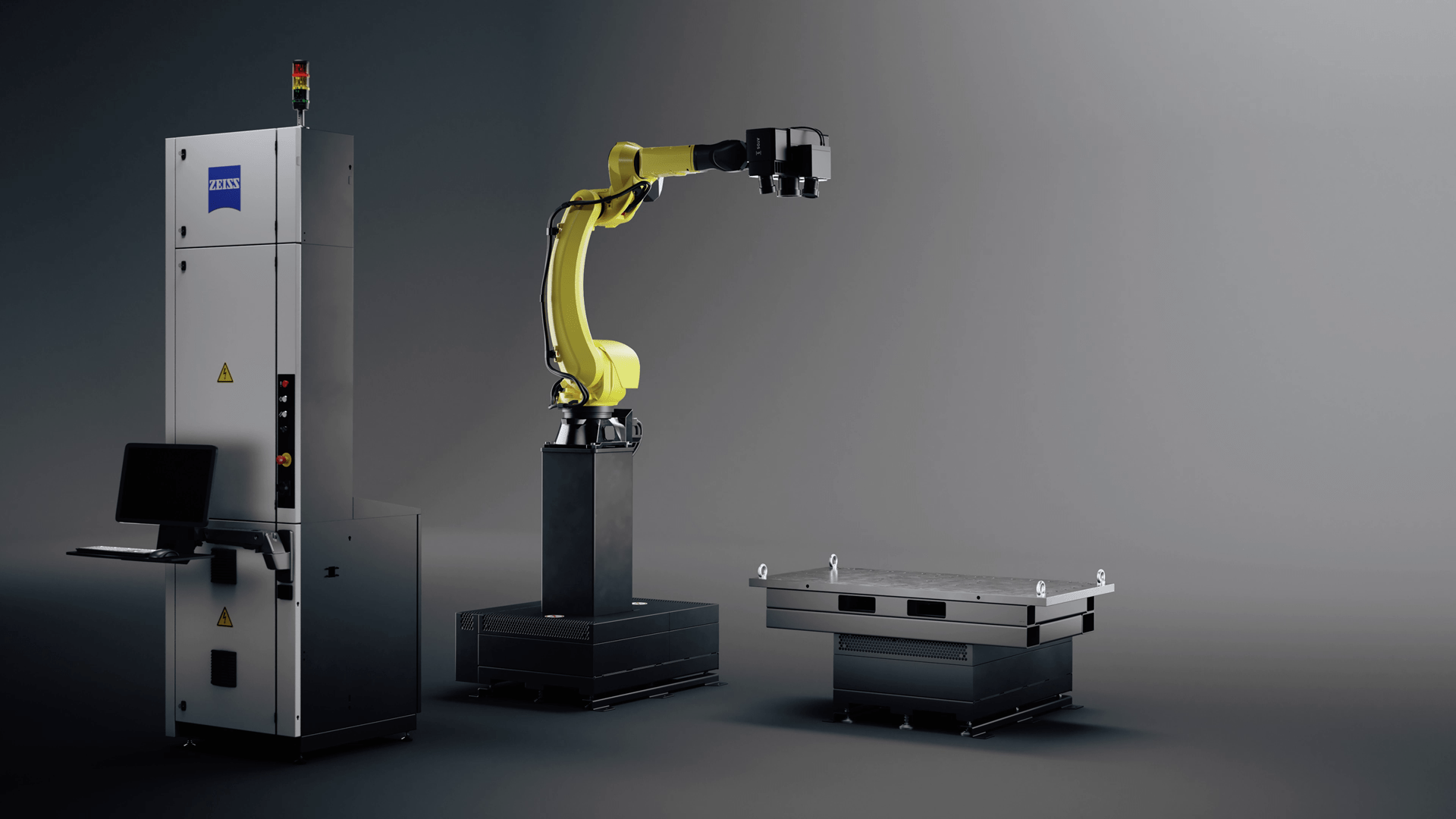

ZEISS ScanBox 5系提供三种机型和多种配置选择,用户可根据自身需求进行定制,这便是我们所说的新模块化概念。系统由多个标准化的独立模块组成,用户可在原系统基础上进行扩展和升级。旋转台模块最大承重高达2000 kg。

ZEISS ScanBox 5110

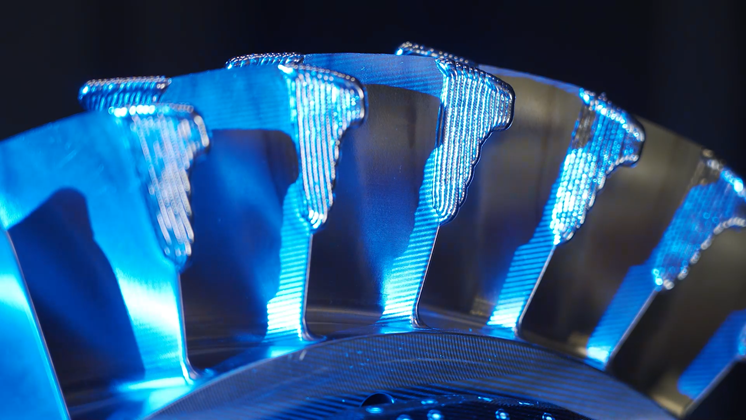

适用于1000 mm以下的复杂翼型的测量和检测

ZEISS ScanBox 5120

适用于大至2000 mm的汽车内饰件的测量和检测

ZEISS ScanBox 5130

适用于大至3000 mm的钣金件,装配件,铸造件和涡轮部件的测量和检测

ZEISS ScanBox 5系:用途广泛,操作灵活

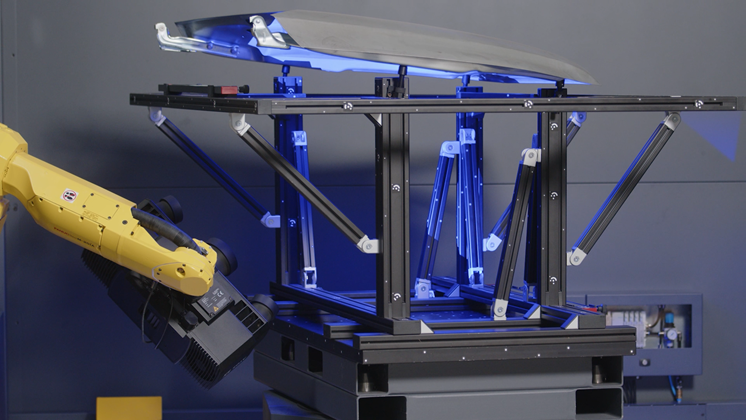

符合人体工学的操作设计

全新的灵活升降式工作站台符合人体工学设计,更好地支持用户日常工作。内置在电子开关柜中的伸缩臂可升降旋转,调节到需要的高度,让操作人员能够站着或坐着操作ZEISS ScanBox 5系。

光学批量测量

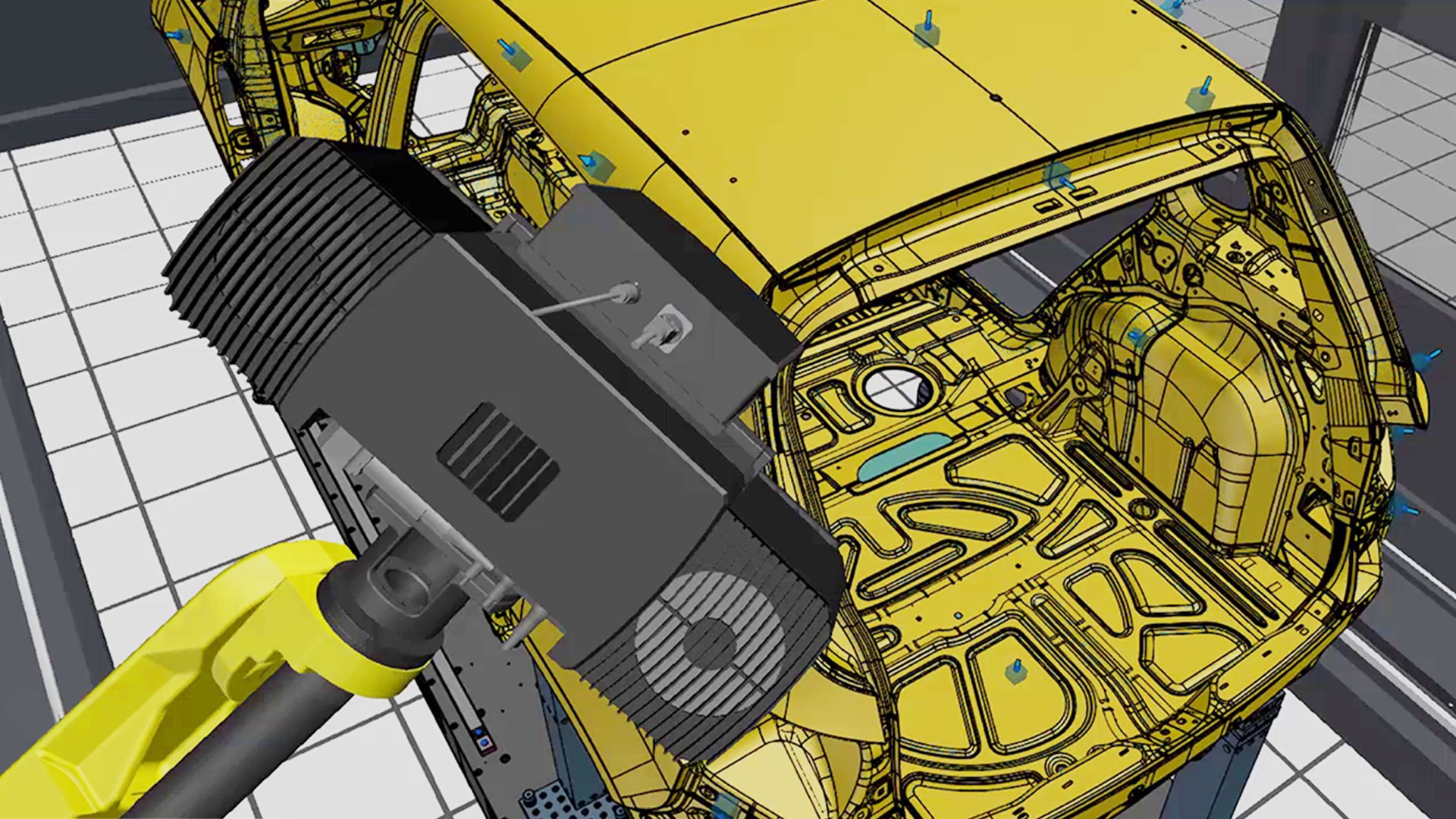

ZEISS ScanBox 5系专为批量检测而研发,可直接用于生产环境。测量程序自动化,确保了相同部件的三维测量数据的可重复性。您可以在GOM Inspect Pro软件的虚拟计量室(VMR)中创建用于检测的测量程序。机器人完全由软件控制,沿着测量位置连续移动。CAD的数据状态或检测计划的变化可以通过软件的参数化性能得到快速更新。整个操作过程方便快捷,操作人员可以轻松操作。

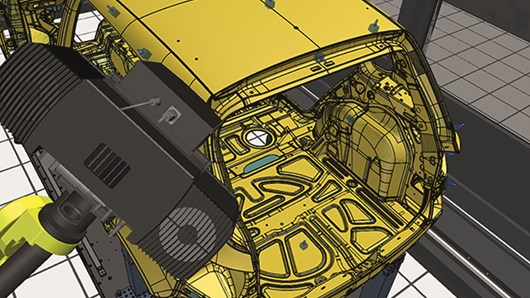

GOM Inspect Pro中的虚拟计量室

虚拟计量室(VMR)是ScanBox所有元件的中央控制和测量规划软件。在VMR中,会模拟真实测量环境,也就是测量单元中的机器人、测量头和零件的功能。对机器人运动路径、夹具和测量计划进行编程。VMR可以自动执行测量程序,不需要用户具备特殊的机器人编程技能。在正式投入实际环境使用之前,所有的机器人的运动都会经过仿真模拟和检查,以确保安全。

测头兼容性

ATOS测量头每次测量都提供全域3D坐标。在短短几秒钟内便可采集到1200万个独立测量点。因此,测量数据细节还原度高,即使是非常小的零件特征也能够轻松还原。

技术参数

| ZEISS ScanBox 5110 |

ZEISS ScanBox 5120 |

ZEISS ScanBox 5130 | |

| 尺寸 | 2200 × 3550 × 3050 mm (安全光幕) 2200 x 2850 x 3050 mm (安全门) |

3600 × 4250 × 3050 mm (安全光幕) 3600 x 3550 x 3050 mm (安全门) |

4300 x 4250 x 3050 (安全光幕) |

| 电源 | 200–500 V(3相,16 A) |

200–500 V(3相,16 A) |

200–500 V(3相,16 A) |

| 最大零件尺寸 | Ø 1000 mm |

Ø 2000 mm |

Ø 3000 mm |

| 最大承重 | 2000 kg |

2000 kg |

2000 kg |

| 保护装置 | 安全光幕或是带安全开关的滑门 |

安全光幕或是带安全开关的滑门 |

安全光幕 |

| 入口宽度 | 1000 mm (安全光幕) 950 mm(安全门) |

2400 mm(安全光幕) 2100 mm (安全门) |

3100 mm (安全光幕) |

| 地面安装或固定 | 需要 |

需要 |

需要 |

| 装卸方式 | 手动,起重机 (安全门) | 手动,运输车,托盘车,起重机(安全光幕) |

手动,运输车,托盘车,起重机(安全光幕) |

| Sensor compatibility | ATOS 5 for Airfoil |

ATOS 5, ATOS 5 for Airfoil |

ATOS 5 |

服务

购买和安装三维测量系统后的服务范围