ScanBox 7系

Quality Assurance for Large Parts

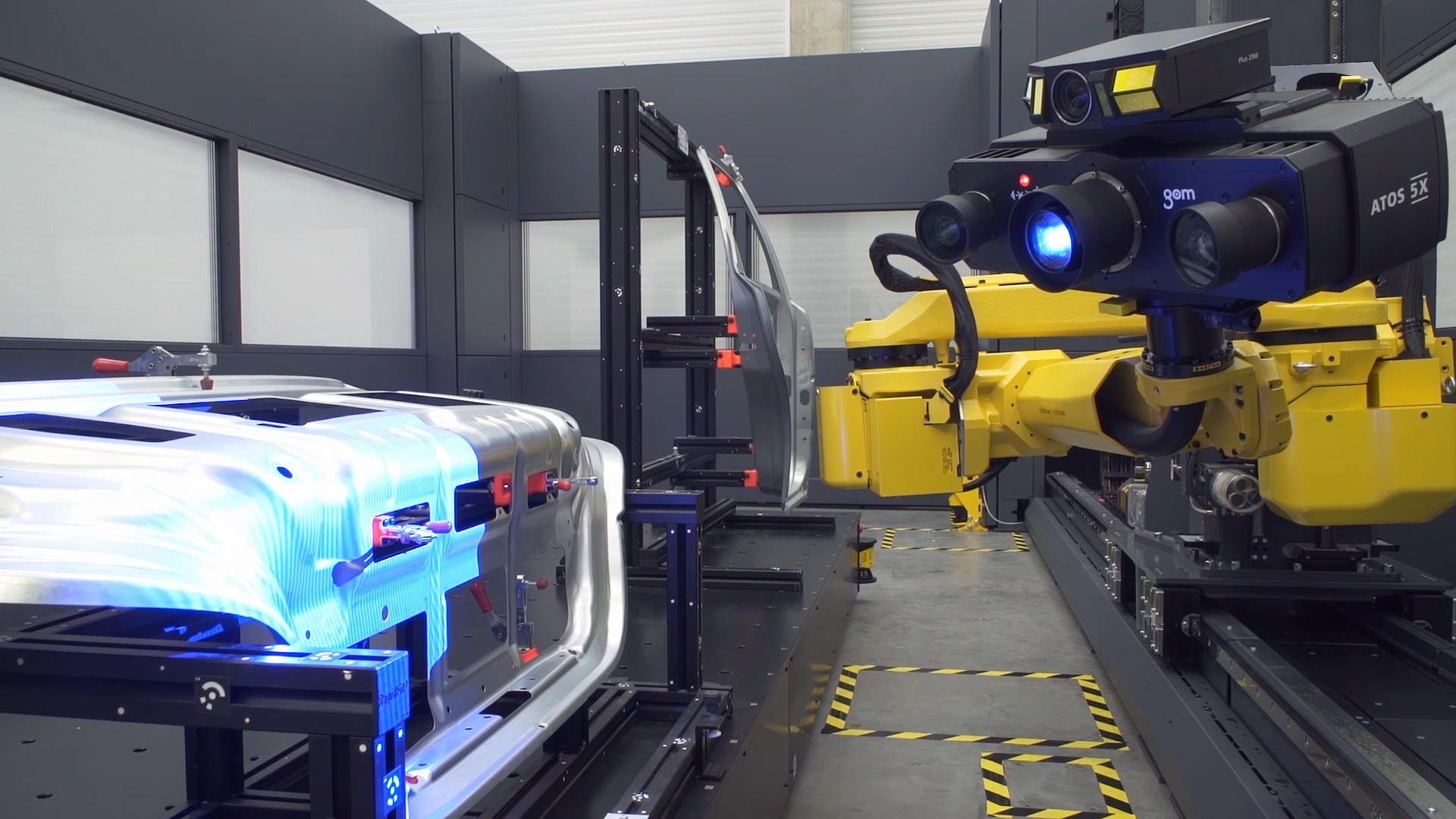

Automated 3D measurement technology for car manufacturing, try-out toolmaking and press shops: With ATOS ScanBox Series 7 you digitize and inspect large and heavy parts, such as automobile side panels and attached parts of up to 10 meters in size. In addition, welded assemblies for transportation, mechanical engineering and aircraft construction can be measured.

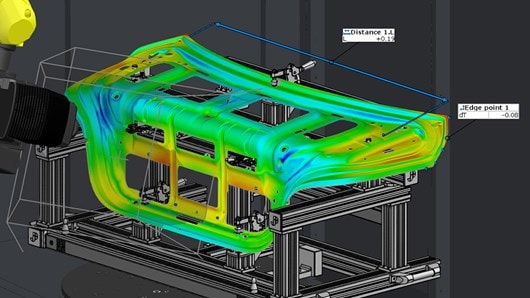

Create complete analysis measurements with the optical 3D measuring machine for a comparison in the try-out phase. Use the numerous features of the powerful GOM Inspect Pro software and evaluate hole patterns, trimmed edges and character lines.

ATOS ScanBox 7160

In the measuring cell, the high-speed sensor captures particularly large and heavy parts with a maximum size of 6000 x 1250 mm. Special designs make it possible to measure parts 10 meters in size.

ATOS ScanBox 7260

Thanks to the additional rotation table working area, you will succeed in measuring medium-sized parts with a maximum weight of up to 2000 kg.

Flexible sensor positioning and large measuring areas

Due to the 8-axis kinematics – a combination of a horizontal rail, a vertical lift and an articulated robot – you succeed in full-field measurements of large and heavy parts. Thanks to 8 degrees of freedom, the ATOS sensor is very flexible in its positioning and measures 3D data of the smallest details in the shortest possible time. The high resolution reduces the number of measurements and speeds up your workflow.

One system – adaptable to your needs

Flexible Loading Options

ATOS ScanBox Series 7 can be loaded with a driverless sandwich panel transport system including a track system, drive computer and safety systems. Alternatively, the parts can also be transported into the respective working area by transport cart, pallet truck, crane or forklift truck.

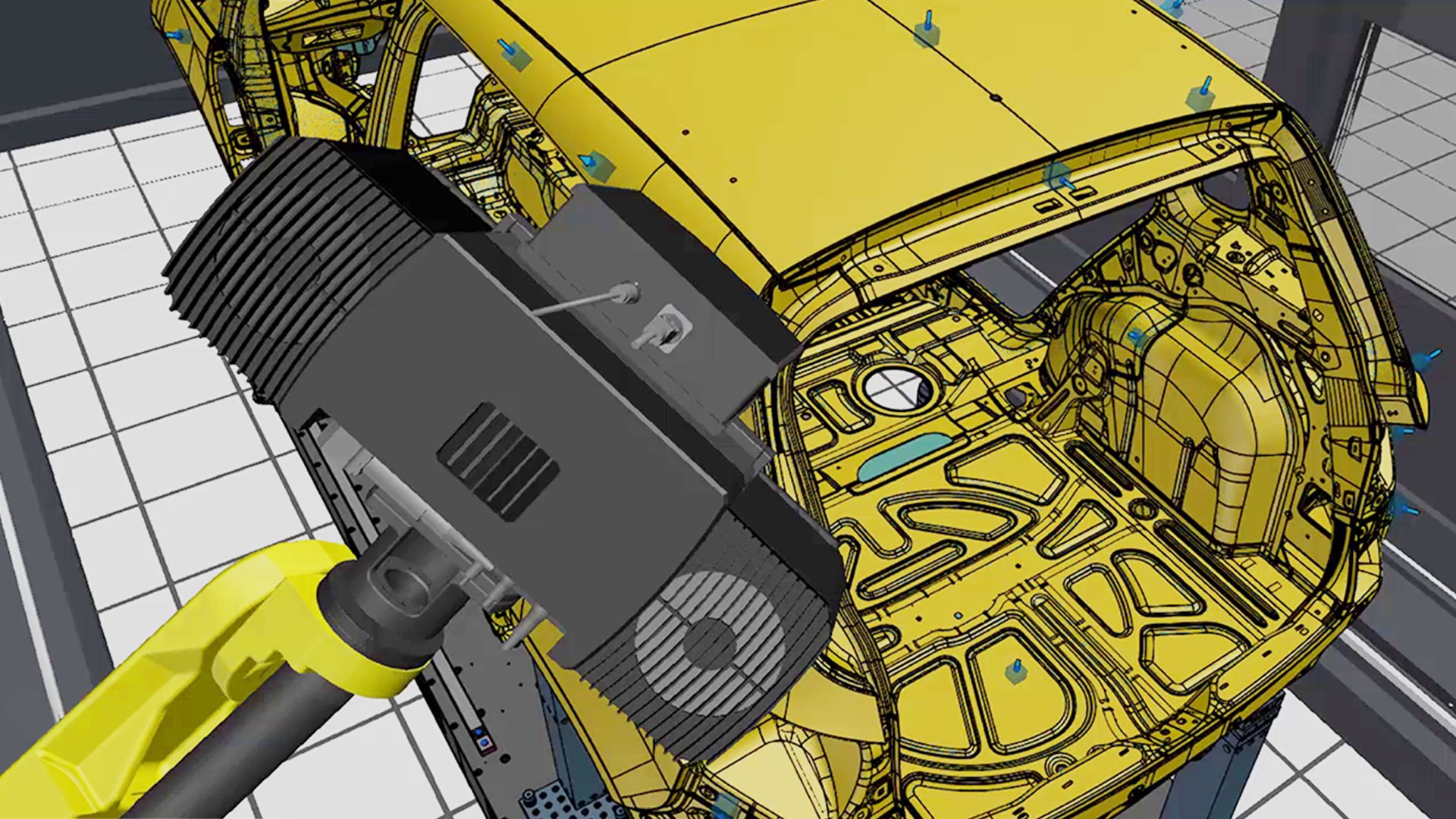

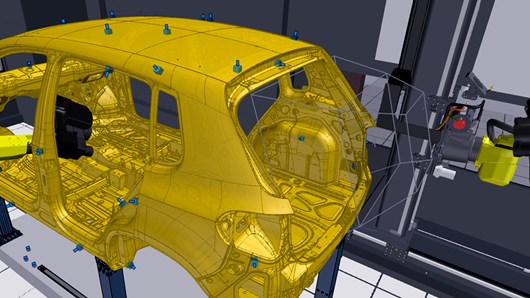

Virtual Measuring Room

The virtual measuring room (VMR) is the central control station and measurement planning software for all elements of the ATOS measuring cells. In the VMR, the real environment, i.e. robots, sensors and parts in the measurement cell, is functionally simulated in a simulation. The programming includes the kinematics, the robot paths, the part fixture and the measurement plan. Thanks to the VMR, the user can work with the system without requiring specific robot programming skills. All robot movements are simulated and checked for safety before being performed in the actual environment.

Sensor Compatibility

ATOS sensors provide full-field 3D coordinates for each individual measurement. Within a few seconds, up to 12 million independent measuring points are captured per scan. As a result, the measuring data are characterized by a high detail reproduction, which enables you to also measure very small parts.

技术参数

| ATOS ScanBox 7160 | ATOS ScanBox 7260 | |

| 尺寸 | 4750 × 10150 × 3900 mm³ | 8750 × 10150 × 3900 mm³ |

| 电源 | 200–500 V (3相, 32 A) | 200–500 V (3相, 32 A) |

| 最大零件尺寸 | 6000 × 2500 mm | 6000 × 2500 mm,转台区最大零件尺寸Ø 3000 mm |

| 最大零件重量 | 不限 | 不限,转台区最大零件重量2000 kg |

| 出入口 | 安全光帘 | 安全光帘 |

| 开口宽度 | 3050 mm | 3050 mm,转台区最大零件尺寸Ø 3400 mm |

| 地面安装或固定 | 需要 | 需要 |

| 装载方式 |

手动装载,运输车、托盘车、起重机、叉车夹、芯板运输系统装载 | 手动装载,运输车、托盘车、起重机、叉车夹、芯板运输系统装载 |

| 测头兼容性 |

ATOS 5, ATOS 5X | ATOS 5, ATOS 5X |

Services

-

GOM Care

Support and services on a contractual basis for all 3D measuring systems from GOM.

-

GOM Training – Automation VMR

In this two-day training, you will get to know the complete process for the creation and execution of automation projects from scratch to the final mesh.

-

GOM Training – Measuring Large Objects in ATOS ScanBox Series 7 and 8

This eLearning guides you step by step through the complete process of robogrammetry and shows how to prepare, use and optimize robogrammetry in the GOM software and at ATOS ScanBox.