ZEISS ScanBox Series 5 RC

与生产相关的质量控制和批量监控

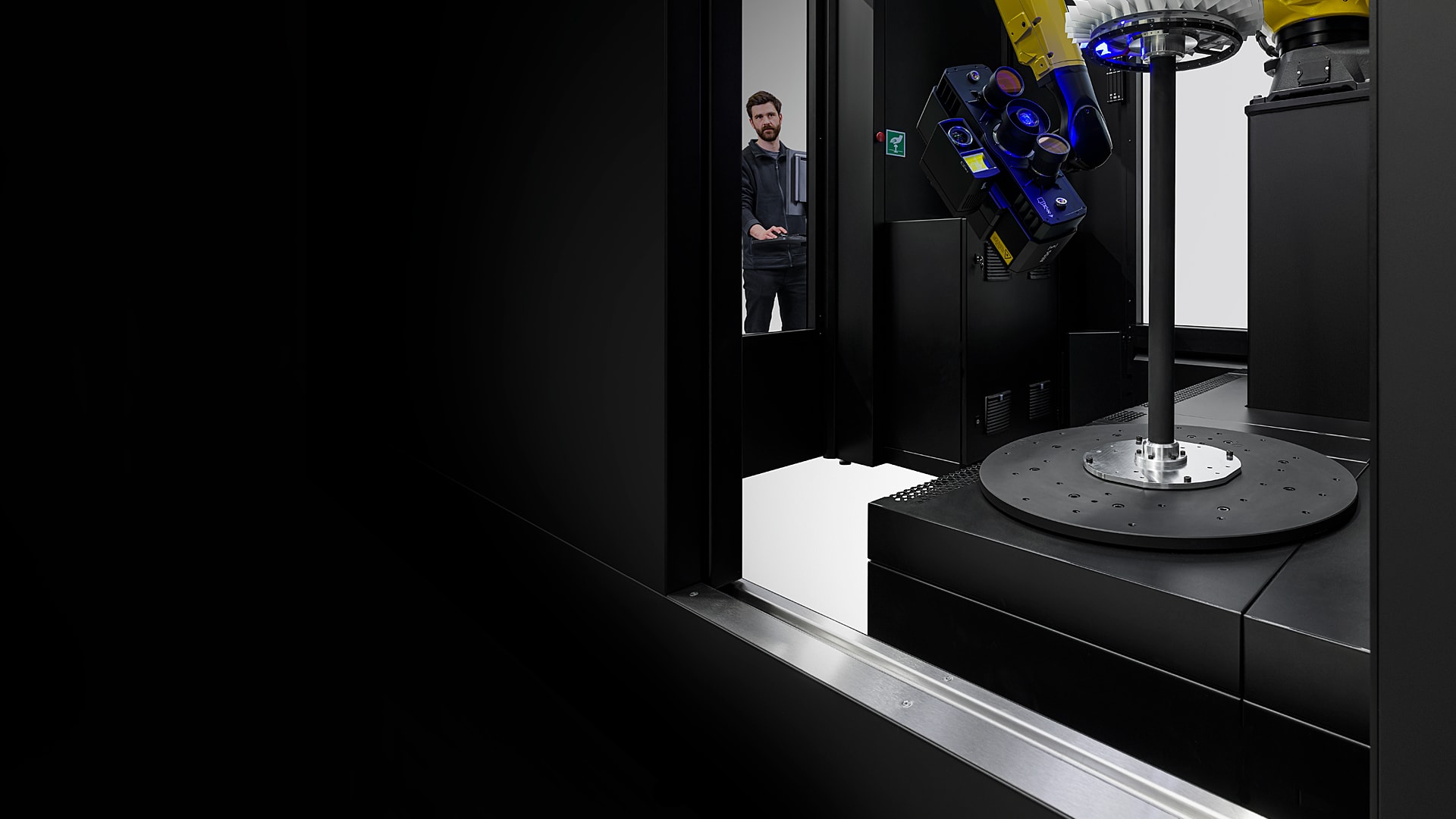

ZEISS ScanBox Series 5 RC(遥控)是一款配备电动滑门的光学测量系统。通过机器人或定制的装载系统,可以将翼型件、附属件或工具等部件自动装载到ZEISS ScanBox Series 5 RC中,并将它们放置在转动台组件上。由于用户不需要每次单独放置零件,因此质量保证所需的时间大大缩短。自动运行提高了系统的利用率、加快了测量周期,让您能够更有效地安排工作人员的工作。ZEISS ScanBox Series 5 RC提供两种型号供选择,并且专门针对需要高度集成和高产量的应用而设计。这套系统占用面积小,因此可顺利集成到每一条生产线中。

高产量和高可重复性

精确的测量流程以及最佳的可比较性

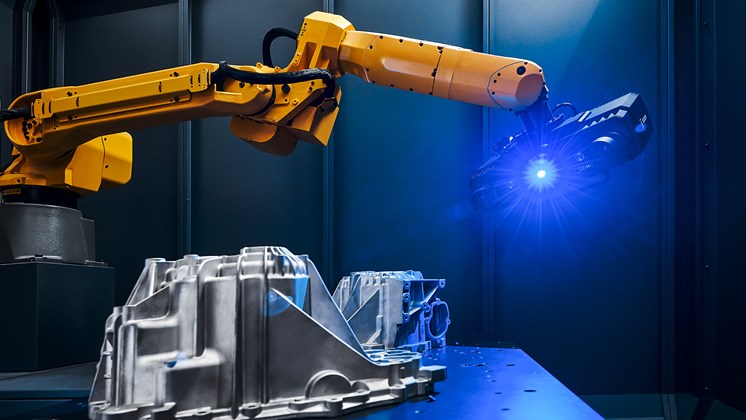

在批量生产期间进行的质量控制包括监控生产过程、减少废品并最大限度地降低返工的需要。对于这类应用,ZEISS ScanBox Series 5 RC光学测量系统正是最理想的解决方案。使用ATOS 5测量头、完全在三维中创建的批量部件的实际坐标,可以直接与CAD模型或测量计划中的技术规格进行比较。您可以直接在生产设施中创建检测报告,并将其输出至统计过程控制系统。

最大的系统利用率和优化的流程

如果您希望发挥ZEISS ScanBox Series 5 RC的全部潜力,可以将光学测量系统与ZEISS提供的进料和装载系统组合使用。ZEISS Integration系列产品能自动装载部件,因此可以避免停机时间。这样就能让部件流和运行时间两者都得到最优化。

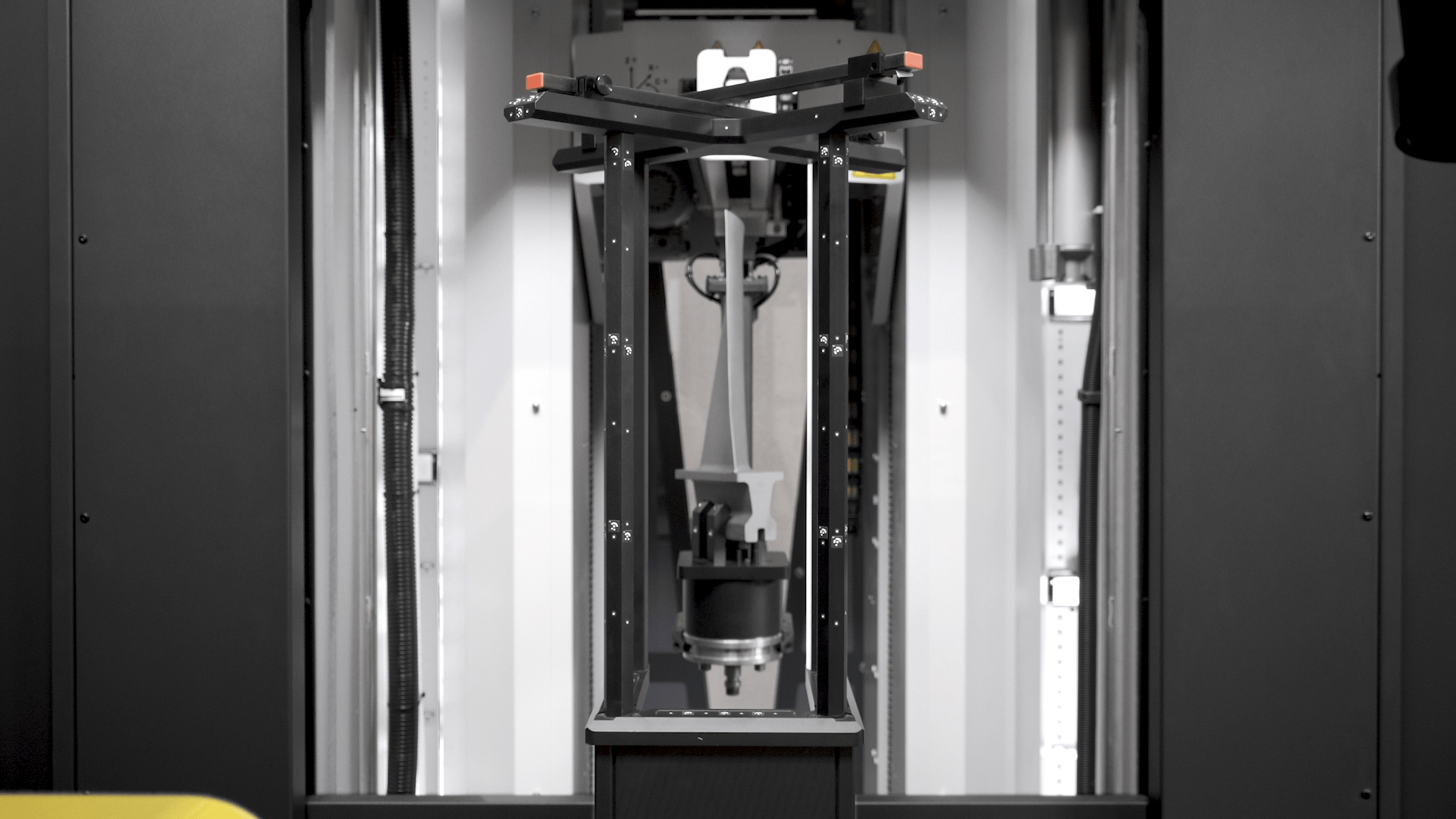

配备料仓装载系统的自动化技术

集成料仓装载系统可以增加周期时间并减少人员需求——系统自动测量周期时间可延长到最多11个小时。在料仓装载系统中,可以手动堆垛比如涡轮叶片等成批部件。在每一个标准支架上都标有特定的RFID芯片,以用于识别。根据芯片上的信息,系统会自动选择适当的测量程序。在完成检测之后,部件会自动返回。

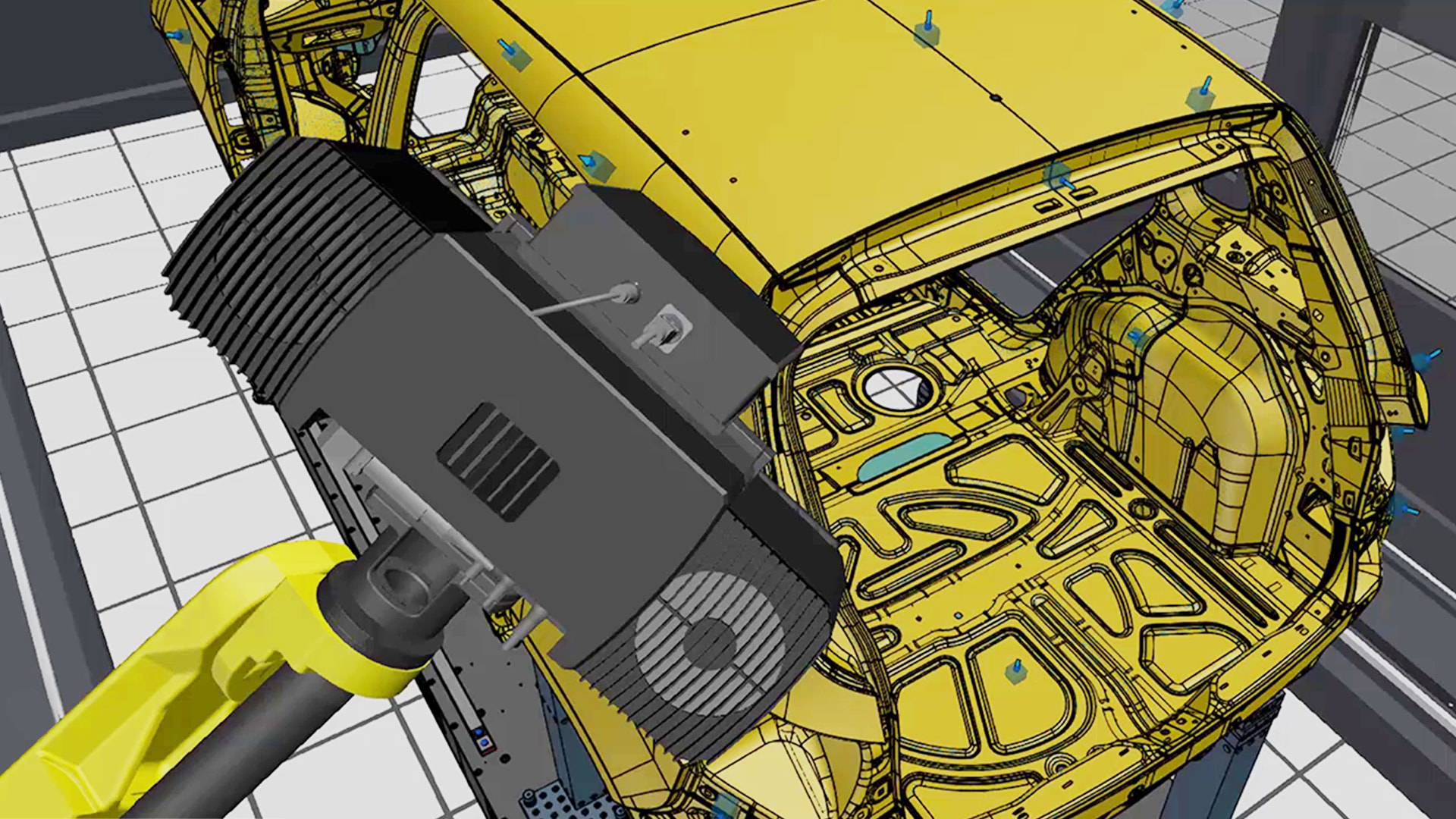

三维测量软件中的虚拟计量室 (VMR)

虚拟计量室 (VMR) 是适用于光学测量间中所有元件的中央控制和测量规划软件。VMR通过模拟表现出真实环境的功能特性,即模拟机器人、测量头和测量间中的部件。编程包括机器人运动轨迹、标准支架和测量计划。通过虚拟计量室,用户即使没有特定机器人编程技能也能够正常运行系统。在正式投入实际环境使用前,机器人的一切运动路径和活动均经过重重模拟和检查,确保操作安全性。

测量头兼容性

ATOS 测量头为每一次测量提供全场三维坐标。凭借单次扫描,可以捕捉到1200万个独立测量点,过程仅需数秒。因此,测量数据的细节重现度极高,并可以摄取到极小的部件特征。

技术参数

| |

ZEISS ScanBox 5110 RC |

ZEISS ScanBox 5120 RC |

| 尺寸 |

2200 x 2850 x 3050 mm |

3600 x 3550 x 3050 mm |

| 电源 |

200–500 V(三相,16 A) |

200–500 V(三相,16 A) |

| 零部件最大尺寸 |

Ø 1000 mm |

Ø 2000 mm |

| 零部件最大重量 |

2000 kg |

2000 kg |

| 出入口 |

带有安全开关的滑门 |

带有安全开关的滑门 |

| 滑门打开宽度 |

1000 mm |

1350 mm |

| 装载方案 |

通过电动滑门自动装载,或者通过安全门手动装载 |

通过电动滑门自动装载,或者通过安全门手动装载 |

| 测量头兼容性 |

ATOS 5 for Airfoil, ATOS 5* |

ATOS 5*, ATOS 5 for Airfoil |

* 需要验证设置

服务支持

GOM为购买和安装过三维测量系统的客户提供持续的服务和技术支持。