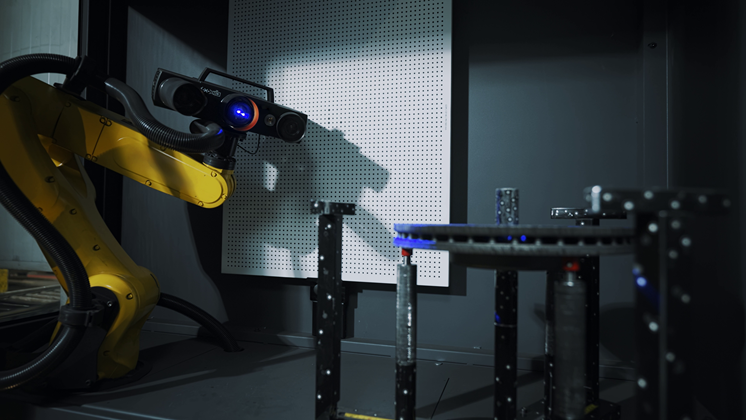

ScanBox 4系

ATOS ScanBox 4系

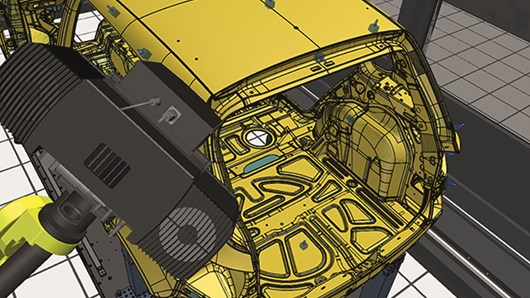

即插即用:ATOS ScanBox 4105可快速高效地检测大至500 mm的小型复杂零部件。只需在安装地点提供适用电源,即可顺利运行这一光学三维测量设备。ATOS ScanBox 4105尺寸紧凑,移动灵活,底部装有四个滑轮,可轻松在生产车间或测量室内移动使用。按下启动按钮,便可以通过Kiosk界面和GOM Inspect软件的虚拟计量室 (VMR) 模块执行所有测量和检测过程。

开机快速,易于处理

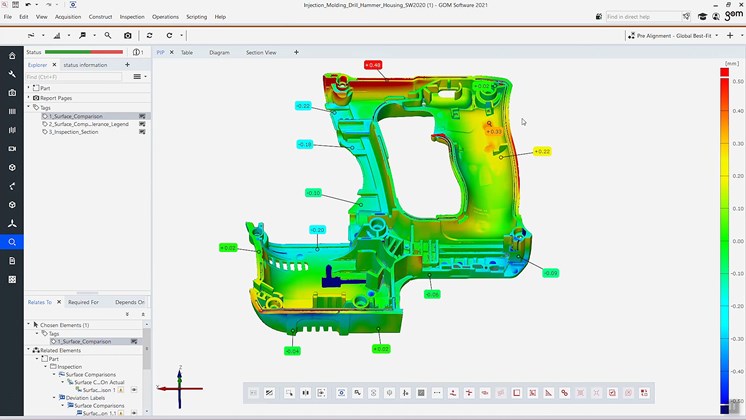

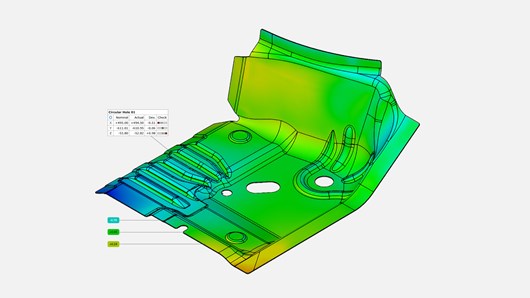

使用ATOS ScanBox 4105 对注塑件、压铸件、模具、模型、冲压件和弯曲件进行有效的质量控制,体验紧凑型三维测量设备的出色性能。

测头兼容性

ATOS测头提供全场三维坐标。单次扫描可捕捉多达1600万个测量点,过程仅需几秒钟。ATOS Q两款测头具备出色的细节重复性,非常适用于测量极小的零部件。

Exclusive customer insights: Metrology Stories

Hirschvogel Group

The Hirschvogel Group is one of the largest international automotive suppliers in the installation surface of steel and aluminum forging as well as subsequent machining. Quality assurance of wheel hubs is executed at the Denklingen site with four production-integrated ATOS ScanBox 4105 systems.

Buderus Guss

The automotive supplier Buderus Guss produces around 15 million passenger car brake discs a year at its site in Breidenbach. In the production process, the European market leader uses both scrap metal from industry and recycled material from its own production. Automated quality assurance is done with a production integrated ATOS ScanBox Series 4.

技术参数

| ATOS ScanBox 4105 | ||

| 尺寸 | 1600 × 1200 × 2100 mm³ | |

| 电源 | 标准电源,100-240 V(单相,16 A) | |

| 最大零件尺寸 | Ø 500 mm | |

| 最大零件重量 | 100 kg | |

| 入口 | 带安全开关的滑门 | |

| 开口宽度 | 685 mm | |

| 地面安装或固定 | 不需要,可移动 | |

| 装卸方式 | 手动,起重机 | |

| 兼容测头 | ATOS Q |