ScanBox Series 4

ATOS ScanBox Series 4

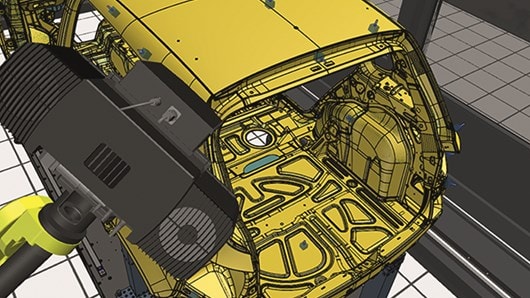

Ready for immediate use thanks to plug-and-play concept: ATOS ScanBox 4105 allows for fast and efficient inspection of small and complex parts up to 500 mm in size. For using the optical 3D measuring machine, only a normal power connection is required at the place of installation. ATOS ScanBox 4105 is compact and mobile at the same time – four wheels allow easy repositioning within the production hall or in the measuring room. At the push of a button, you can execute all measurement and inspection processes via the Kiosk Interface and the virtual measuring room (VMR) in GOM Inspect Pro.

Immediately Ready for Operation and Easy Handling

Use ATOS ScanBox 4105 for efficient quality control of your injection-molded parts, die cast components, tools, molds or stamping and bending parts and convince yourself of the performance of this compact 3D measuring machine.

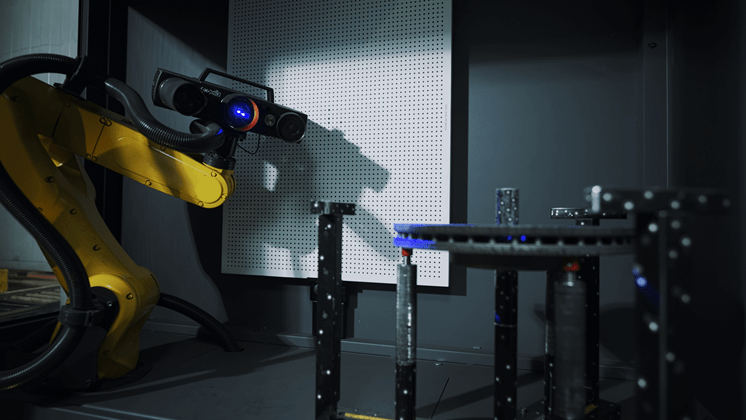

Fast & precise

ATOS sensors provide quality information in a high level of detail for subsequent analysis in a short time. By using a multi-part fixture, you can measure several parts in one run – even in 24/7 operation if required: increase throughput – produce less scrap – standardize quality assurance.

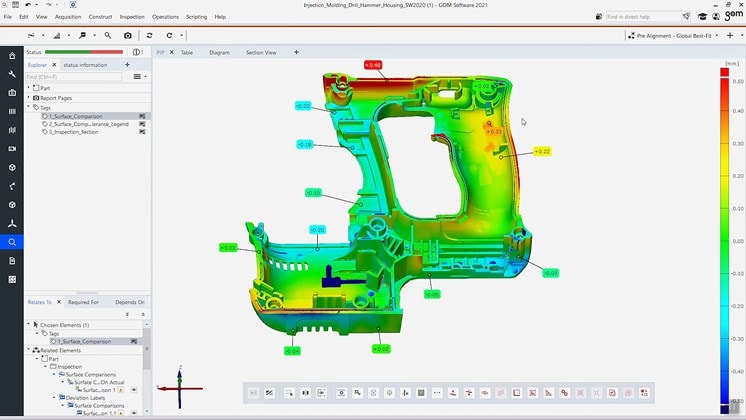

All-in-one software

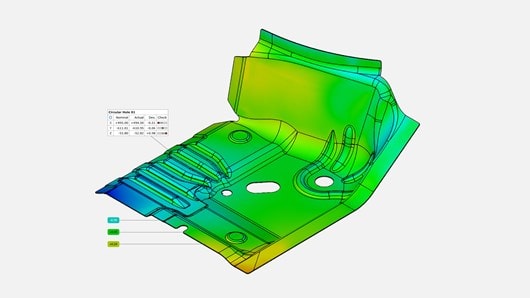

GOM Inspect Pro offers everything from a single source: scanning, inspection and reporting. Examine nominal-actual comparisons as well as GD&T tolerances directly with the Kiosk Interface. Implement necessary corrections directly thanks to easy-to-understand results: analyze completely – receive comprehensive reporting – integrate measurement results into existing processes.

Sensor Compatibility

With each scan, ATOS sensors provide full-field 3D coordinates within a few seconds. Each individual measurement consists of up to 12 million independent measuring points. The excellent detail reproduction in the measurement data makes ATOS Q suitable for measuring very small parts.

Exclusive customer insights: Metrology Stories

Hirschvogel Group

The Hirschvogel Group is one of the largest international automotive suppliers in the installation surface of steel and aluminum forging as well as subsequent machining. Quality assurance of wheel hubs is executed at the Denklingen site with four production-integrated ATOS ScanBox 4105 systems.

Buderus Guss

The automotive supplier Buderus Guss produces around 15 million passenger car brake discs a year at its site in Breidenbach. In the production process, the European market leader uses both scrap metal from industry and recycled material from its own production. Automated quality assurance is done with a production integrated ATOS ScanBox Series 4.

Technical Information

| ATOS ScanBox 4105 | ||

| Dimensions | 1600 × 1200 × 2100 mm³ | |

| Power supply | Standard, 100 – 240 V (1-phase, 16 A) | |

| Max. part size | Ø 500 mm | |

| Max. part weight | 100 kg | |

| Entry | Sliding door with safety lock | |

| Opening width | 685 mm | |

| Floor mounting or fixing | Not required, mobile | |

| Loading concept | Manual, crane | |

| Sensor compatibility | ATOS Q |

Services

Our service range after the purchase and installation of 3D measuring systems.

-

GOM Care

Support and services on a contractual basis for all 3D measuring systems from GOM.

-

GOM Training – Automation VMR

In this two-day training, you will get to know the complete process for the creation and execution of automation projects from scratch to the final mesh.

-

GOM Training – Automated Sheet Metal Inspection

The training imparts sound knowledge of the essential measuring principles as well as the automated measuring procedure – individual sheet metal parts and assemblies are efficiently captured and inspected.