ScanBox 6系

生产配套质量控制的两种模式

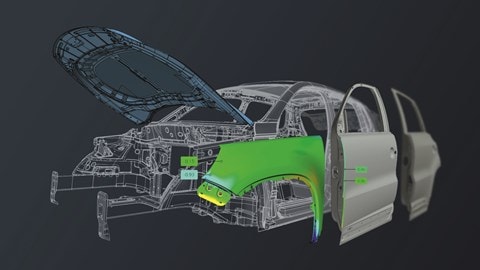

在生产环境中,尽可能快地识别、分析和消除质量问题非常重要。为此,必须在最短的时间内对尽可能多的零件进行全面检查,以便能够在短时间内启动有针对性的纠正措施,尽量减少废品。利用ATOS ScanBox 6系列掌握这一挑战:两个不同的变体提供完整的实际三维坐标和CAD数据之间的全域偏差。

如果您需要检测重量达5000公斤的大型和重型零件,请选择ATOS ScanBox 6135或6235。每台光学三维测量机都配有ATOS系列的工业和高精度三维扫描仪。

高吞吐量

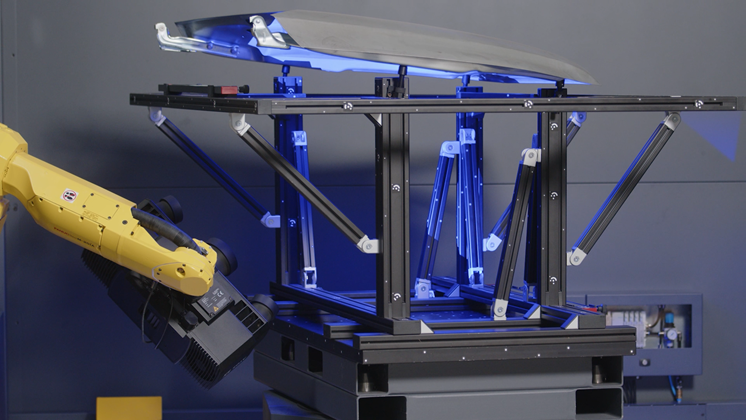

ATOS ScanBox 配有便捷的托盘系统,零部件和固定装置都可以放置在6系外的更换托盘上。通过定位销,可以快速、重复装载托盘,从而极大地提高生产效率,尤其适合批量生产。

装载和测量同时进行

ATOS ScanBox 6235 拥有两个独立工作区,因此工作效率更高。在它的两个工作区或旋转台上,可以放置最大至3.5米的零件,例如铸件、配件以及车前盖。两个工作区可在自动安全光门的保护下安全运行。

简单的装卸方式

快速装卸

设备的出入口设计十分宽敞,使用起重机、叉车或托盘车等装载大型部件到测量设备上时进出方便。

快速更换零件

在使用ATOS ScanBox 6135和6235,诸如行李箱盖和门等附加部件可以用多部件夹具更快地测量,因为不需要更换夹具。多部分夹具可以很容易地定位,以便附件部件可以在前面交换。

将车前盖、车门等汽车配件固定到多部件支架上可以加快ATOS ScanBox 6135和6235的测量速度,无需更换支架即可完成测量。多部件支架定位简单,零部件可以直接从正面更换。

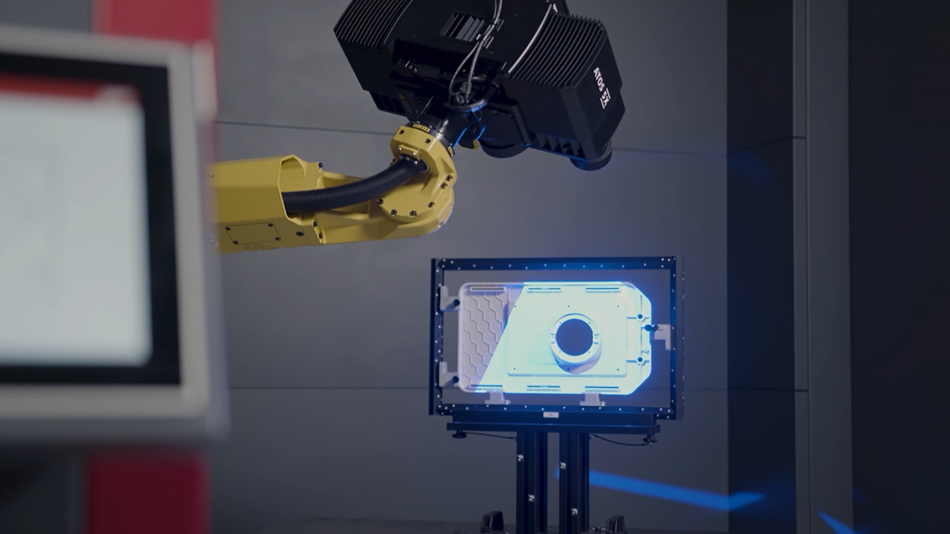

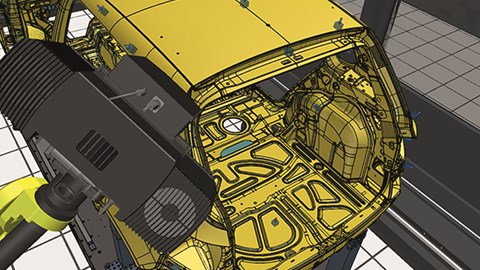

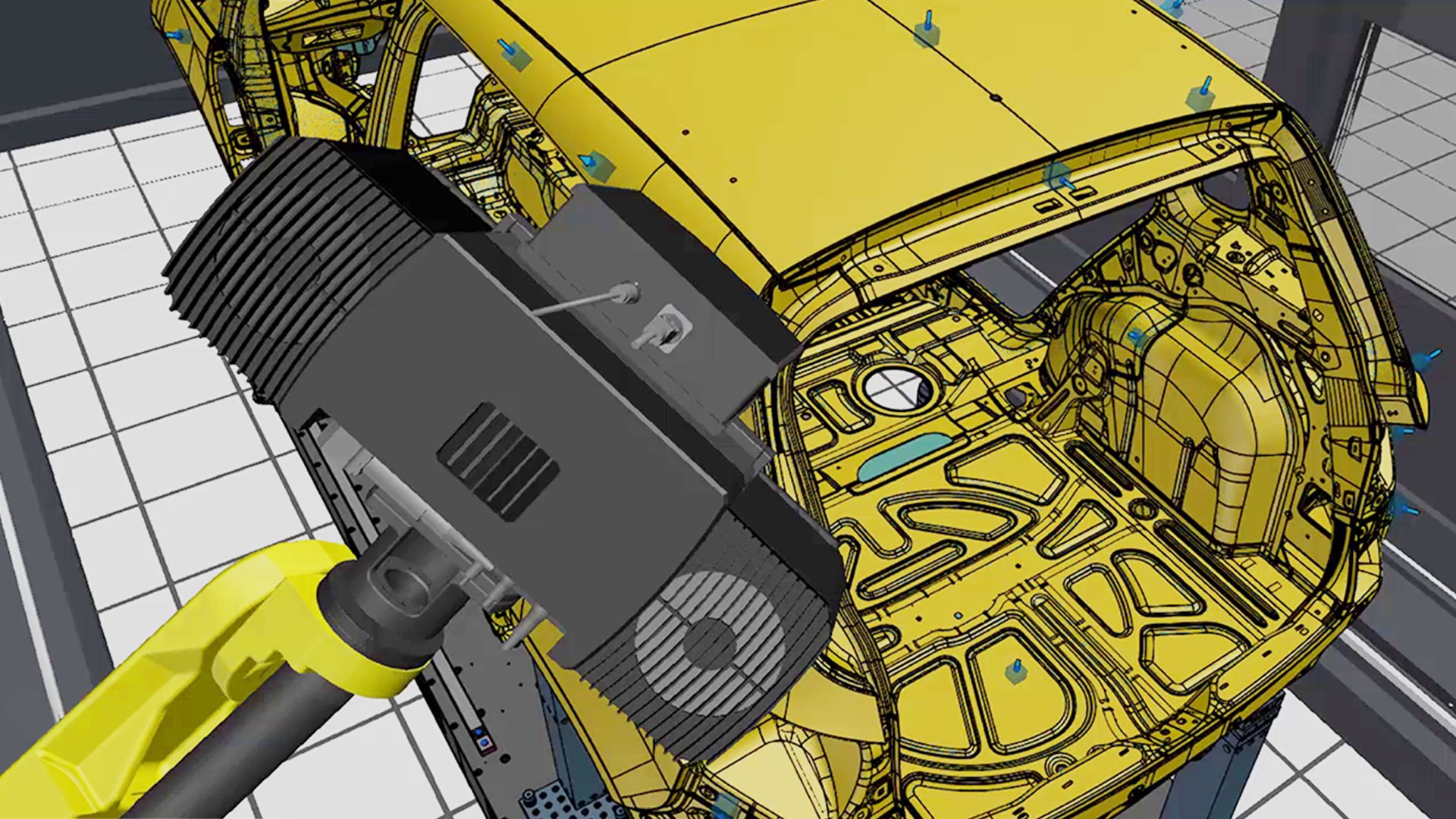

Virtual Measuring Room in GOM Inspect Pro

The virtual measuring room (VMR) is the central control station and measurement planning software for all elements of the ATOS measuring cells. In the VMR, the real environment, i.e. robots, sensors and parts in the measurement cell, is functionally simulated in a simulation. The programming includes the kinematics, the robot paths, the part fixture and the measurement plan. Thanks to the VMR, the user can work with the system without requiring specific robot programming skills. All robot movements are simulated and checked for safety before being performed in the actual environment.

Virtual Clamping for Hang-on Parts

Virtual Clamping technology avoids multiple measurement loops for parts that are typically measured on mechanical fixtures with four support points.

- High accuracies

- Usage of simple fixtures

- Great time saving

Sensor Compatibility

ATOS sensors provide full-field 3D coordinates for each individual measurement. Within a few seconds, up to 12 million independent measuring points are captured per scan. As a result, the measuring data are characterized by a high detail reproduction, which enables you to also measure very small parts.

成功案例

Technical Information

| ATOS ScanBox 6135 |

ATOS ScanBox 6235 |

|

| Dimensions | 4500 × 4500 × 3250 mm | 7665 × 4500 × 3250 mm |

| Power supply | 200–500 V (3-phase, 32 A) | 200–500 V (3-phase, 32 A) |

| Max. part size | Ø 3500 mm |

2× Ø 3000 mm |

| Max. part weight | 5000 kg* | 2× 5000 kg* |

| Entry | Safety light curtains | Safety light curtains |

| Opening width | 2850 mm | 2850 mm |

| Floor mounting or fixing | Required | Required |

| Loading concept |

Manual, transport cart, pallet truck, crane, forklift truck | Manual, transport cart, pallet truck, crane, forklift truck |

| Sensor compatibility | ATOS 5, ATOS 5X |

*in combination with a palett system: 2000 kg