ScanBox Series 6

Two models for production-accompanying quality control

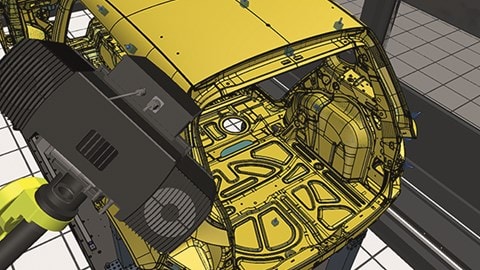

In the production environment, it is important to identify, analyze and eliminate quality problems as fast as possible. For that, as many parts as possible must be completely checked in the shortest amount of time to be able to initiate targeted corrective measures at short notice and to minimize scrap. Master this challenge with ATOS ScanBox Series 6: Two different variants deliver full-field deviations between the complete actual 3D coordinates and the CAD data.

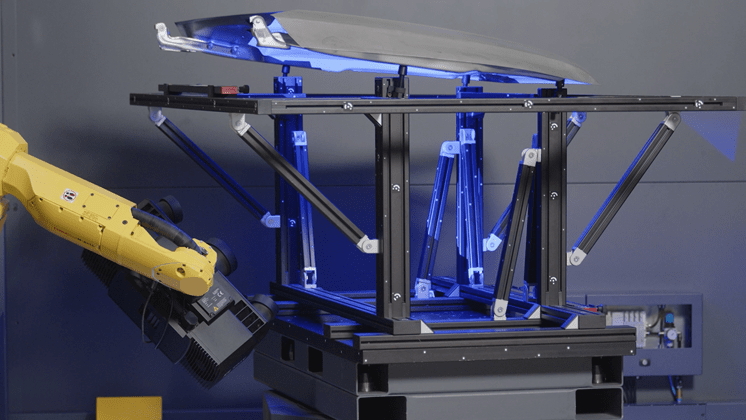

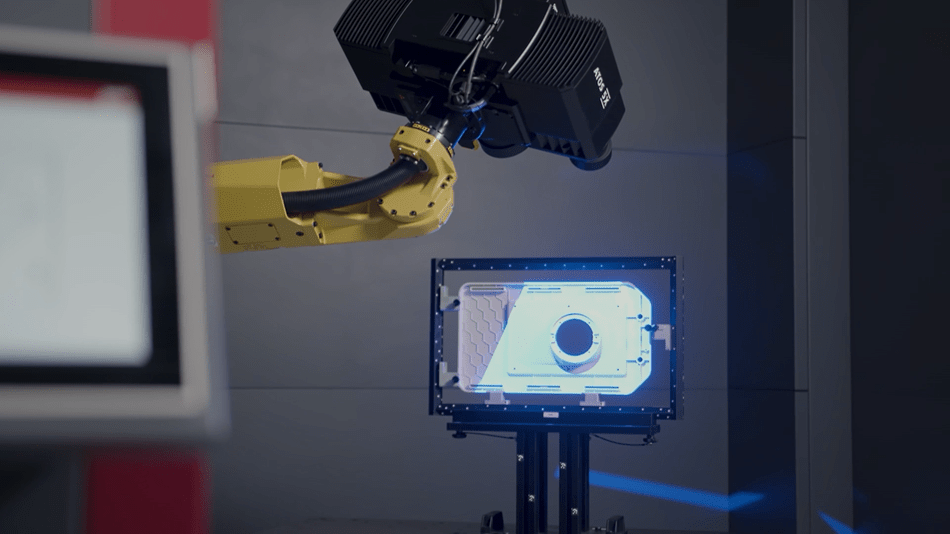

Choose ATOS ScanBox 6135 or 6235 if you need to inspect large and heavy parts with a weight of up to 5000 kg. Each optical 3D measuring machine is delivered with an industrial and high-precision 3D scanner of the ATOS series.

High load capacity

ATOS ScanBox 6135 is constructed for large and heavy parts. For example: cast parts, add-on parts or tools with a size of up to 3.5 m.

High throughput

Set up your parts and the fixtures on changing pallets outside ATOS ScanBox. The pallets are loaded quickly and reproducibly using positioning pins. This results in a high throughput of parts and is ideally suited for series production.

Loading and measuring at the same time

With ATOS ScanBox 6235 you can easily increase your throughput: two working areas can be operated independently from each other. The rotation table can be set up simultaneously to the measurement. In both working areas or on the rotation tables you can place parts such as doors or trunk lids with a size of up to 3.5 m. Both working areas are operated safely due to the automatic doors.

Intuitive loading concept

Quick loading and unloading

Generous entry areas allow for an uncomplicated use of loading machines such as cranes, forklift trucks or pallet trucks. ATOS ScanBox Series 6 can be loaded with large and heavy parts. The maximum load of the rotation table unit is 5000 kg.

Quick change of parts

With ATOS ScanBox 6135 and 6235, car body parts, such as trunk lids and doors, can be measured faster with a multi-part fixture because it is not necessary to change the fixture. The multi-part fixture can be easily positioned so that the attached parts can be exchanged at the front side.

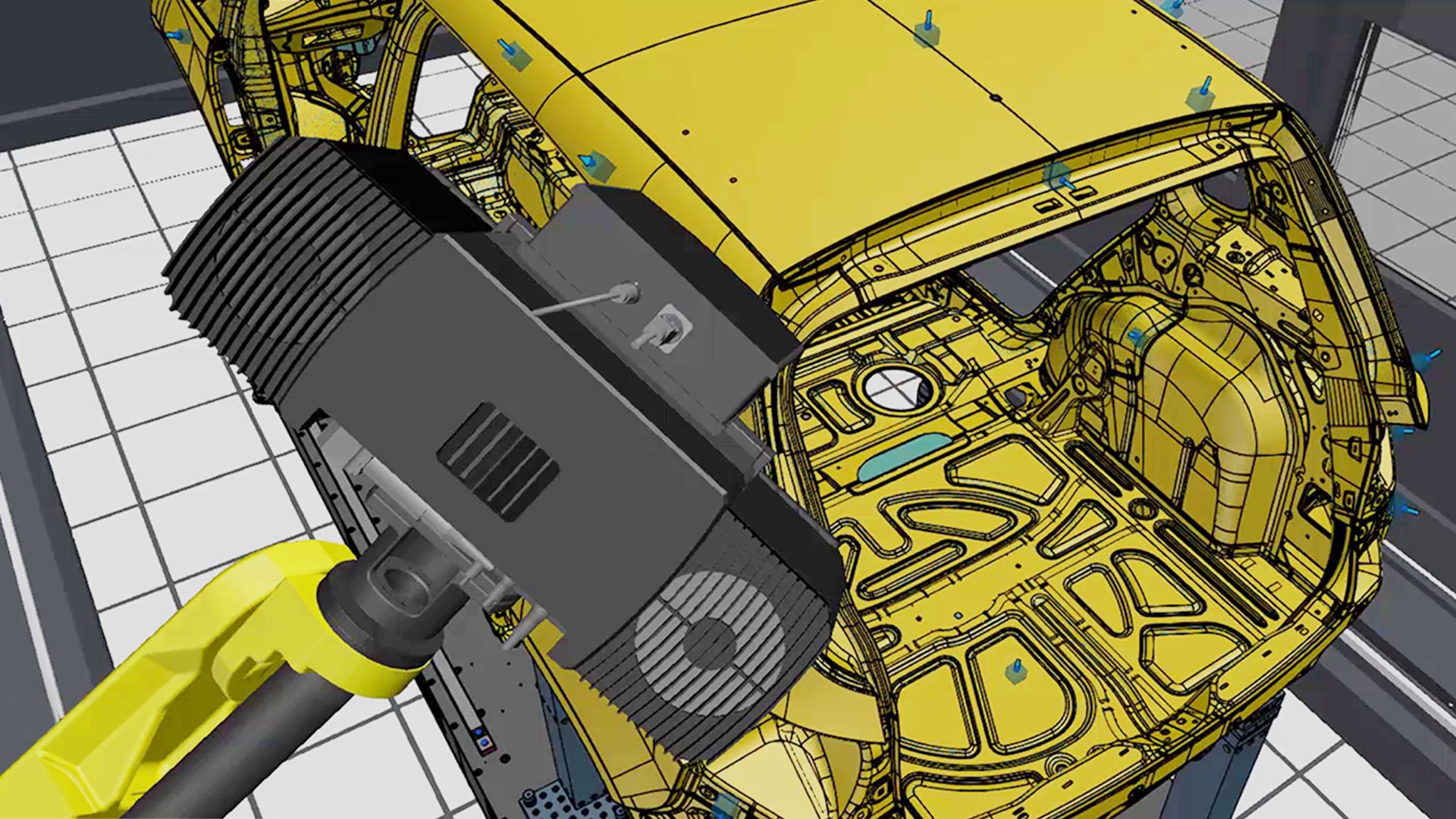

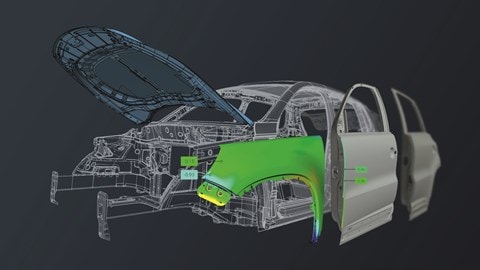

Virtual Measuring Room in GOM Inspect Pro

The virtual measuring room (VMR) is the central control station and measurement planning software for all elements of the ATOS measuring cells. In the VMR, the real environment, i.e. robots, sensors and parts in the measurement cell, is functionally simulated in a simulation. The programming includes the kinematics, the robot paths, the part fixture and the measurement plan. Thanks to the VMR, the user can work with the system without requiring specific robot programming skills. All robot movements are simulated and checked for safety before being performed in the actual environment.

Virtual Clamping for Hang-on Parts

Virtual Clamping technology avoids multiple measurement loops for parts that are typically measured on mechanical fixtures with four support points.

- High accuracies

- Usage of simple fixtures

- Great time saving

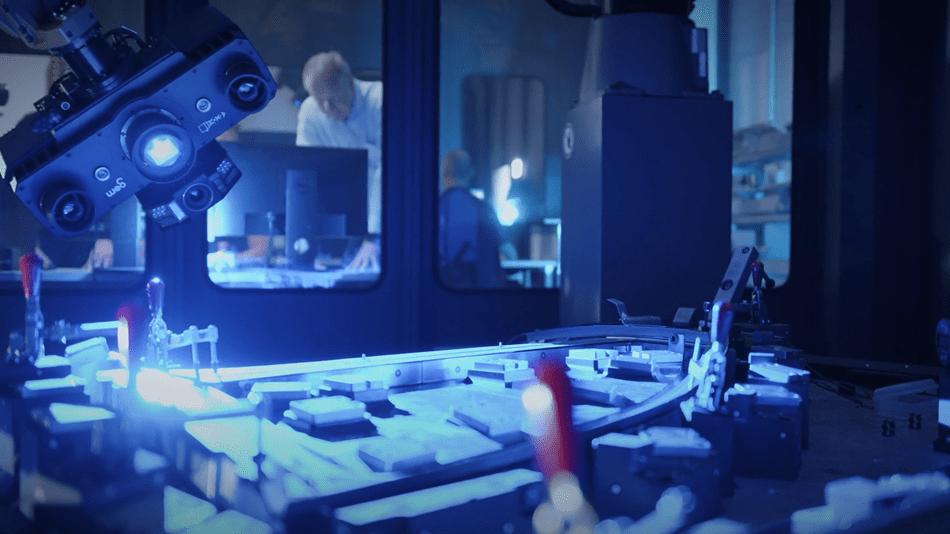

Sensor Compatibility

ATOS sensors provide full-field 3D coordinates for each individual measurement. Within a few seconds, up to 12 million independent measuring points are captured per scan. As a result, the measuring data are characterized by a high detail reproduction, which enables you to also measure very small parts.

Success Stories

Technical Information

| ATOS ScanBox 6135 |

ATOS ScanBox 6235 |

|

| Dimensions | 4500 × 4500 × 3250 mm | 7665 × 4500 × 3250 mm |

| Power supply | 200–500 V (3-phase, 32 A) | 200–500 V (3-phase, 32 A) |

| Max. part size | Ø 3500 mm |

2× Ø 3000 mm |

| Max. part weight | 5000 kg* | 2× 5000 kg* |

| Entry | Safety light curtains | Safety light curtains |

| Opening width | 2850 mm | 2850 mm |

| Floor mounting or fixing | Required | Required |

| Loading concept |

Manual, transport cart, pallet truck, crane, forklift truck | Manual, transport cart, pallet truck, crane, forklift truck |

| Sensor compatibility | ATOS 5, ATOS 5X |

*in combination with a palett system: 2000 kg

Services

GOM Care

With GOM Care, customers receive comprehensive support and services on a contractual basis for 3D measuring systems from GOM. These services include remote support via telephone or online, maintenance and on-site repair and support and service contracts.

GOM Training – Digital Assembly in Car Body Manufacturing

The expert course especially addresses users from the automotive industry. It deals with quality control of the outer skin parts of the car body in assembly situations.

GOM Training – Automation VMR

In this two-day training course, participants carry out the entire measuring procedure in the VMR and create a complete measurement program offline that is subsequently run in ATOS ScanBox.