ARAMIS Adjustable

Grows with Your Requirements

The modularly expandable ARAMIS Adjustable camera system is a cost-effective entry point into the world of digital image correlation. It provides precise 2D and 3D coordinates for the analysis of statically or dynamically strained components and can be used flexibly for various measuring tasks.

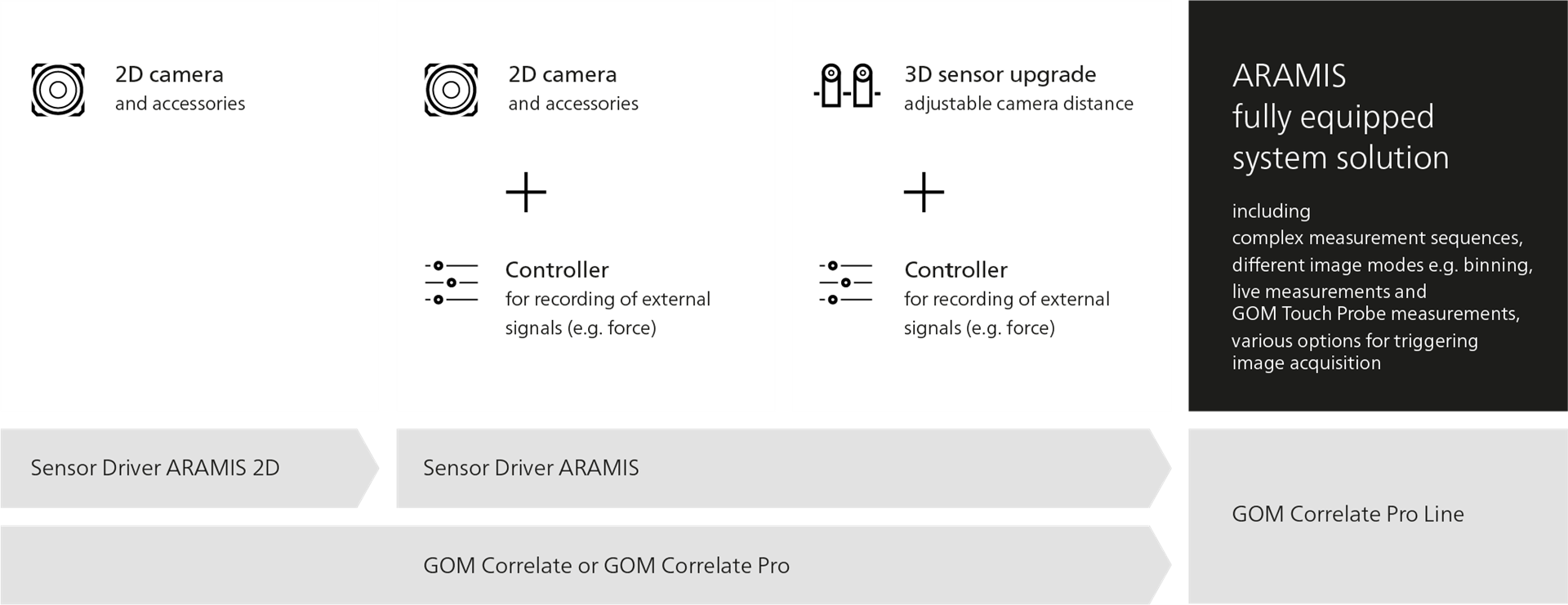

A Modularly Expandable System

Do you need to cover professional metrology tests with a limited budget? Now you can configure ARAMIS Adjustable according to your needs. When your requirements grow, the system grows with them. For instance, the 2D sensor can be easily extended to a 3D system with a second camera. Other system components, such as the ARAMIS Controller, Dual LED lighting, and software, can be added just as easily.

Start small, expand your system later.

| Camera System | 2D Sensor | expand to | 3D Sensor |

| Recording |

Sensor Driver ARAMIS 2D | expand to |

Sensor Driver ARAMIS |

| Image Processing |

ZEISS INSPECT Correlate |

expand to |

ZEISS INSPECT Correlate |

| Training |

eLearning |

expand to |

GOM Training |

| Support |

E-Support |

expand to |

GOM Technical Support |

Flexibly Adjustable Measuring Area

With both a 2D and a 3D sensor, the system is suitable for full-field and point-based analysis of components subjected to static or dynamic strain. Thanks to variable measuring volumes and distances, the sensors can be used flexibly for different measuring tasks. Furthermore, the flexible dual LED lighting allows to illuminate even difficult to access samples from different angles. This makes the system ideal for research institutions and universities working on various applications.

Modular System Solution for Maximum Flexibility

Three camera variants with a resolution of up to 24 megapixels, variable lighting solutions, which can be mounted directly on the sensor, and a powerful software for digital image correlation: The modular design of the ARAMIS Adjustable sensors allows you to choose from a wide variety of components, making it possible to tailor the system perfectly to any measurement task.

Hardware

With its adjustable lenses and variable camera and measuring distances, the flexible design offers many measuring areas within defined measuring volumes.

The associated ARAMIS Controller can be used for easy programming of user-defined measuring sequences, offers image-synchronous signal recording of external measurement signals (e.g., force), transmits analog and digital measurement values and provides numerous options for integrating the system into the testing environment.

Software

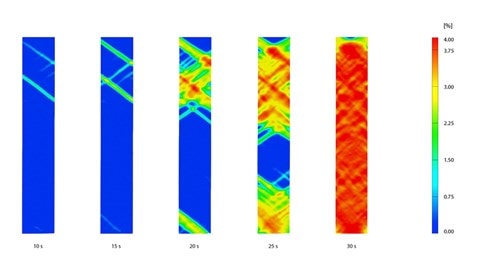

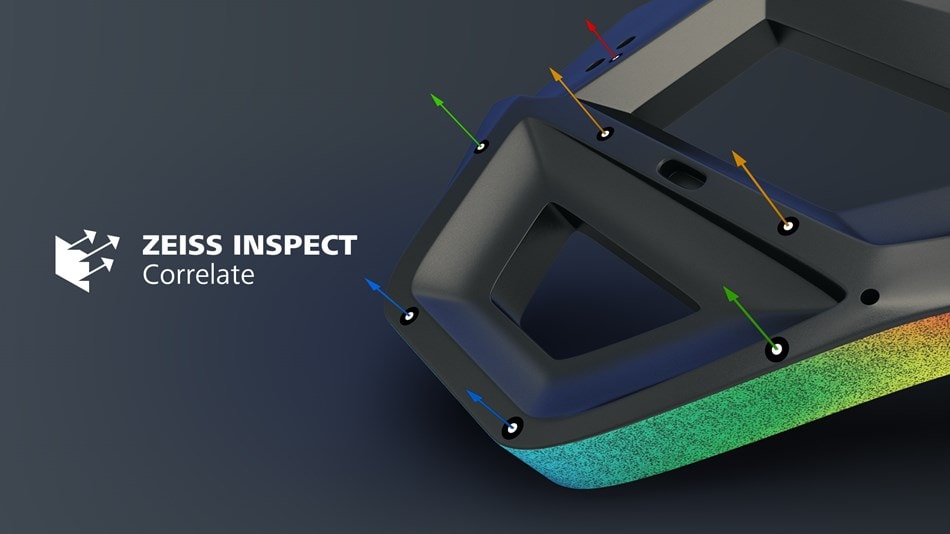

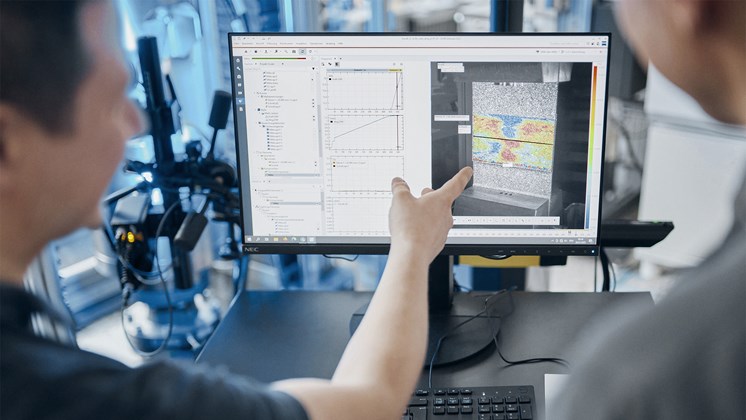

The ZEISS INSPECT Correlate software makes it easy to capture, analyze and evaluate movements and deformations.

The software for 3D testing includes algorithms for digital image correlation and point tracking, evaluations of measurement results, such as 3D displacements, 3D deformations and surface strain, live deformation tracking with data streaming and more.

Accessories

For optimum illumination of very small to medium-sized measurement objects, flexibly positionable dual LEDs or the light projector developed in-house are available. LED Panels, on the other hand, enable a full-field illumination of larger measurement objects.

All three lighting solutions use Blue Light Technology and provide uniform illumination of the surface. In addition, the optically tracked touch probe can perform tactile 3D measurements. With its touch elements, it can even capture areas that are difficult to access optically, making it easy to set up test fields or testing machines.

Technical Data for ARAMIS Adjustable 2D/3D

With a total of three standard camera variants between 12 and 24 megapixels and frame rates from 25 to 2,000 fps, ARAMIS Adjustable is designed for a variety of possible applications in research, development and industry. If recording rates beyond 2000 fps are required, measurements can be realized with high-speed cameras.

| 12M (2D/3D) | 24M (3D) | SRX (3D) | High Speed (2D/3D) | |

| Camera resolution | 4096 x 3000 pixels | 5312 × 4448 pixels | 4096 x 3068 pixels | up to 2048 x 2048 pixels |

| Frame rate (fps) | up to 150 fps | 100 fps (up to 360 fps) | 75 fps (up to 480 fps) |

e.g. 6400 fps (up to 200000 fps) e.g. 16000 fps (up to 1000000 fps) |

| Measuring area (mm) | 20 x 15 mm² up to 5000 x 4000 mm² |

20 x 18 mm² up to 5000 x 4500 mm² |

33 x 25 mm² up to 5000 x 4000 mm² |

10 x 10 mm² up to 5000 x 5000 mm² |

Accessories

- Touch Probe

- Calibration object

- Reference point markers

- Deformation spray package

- Stand

- Transport case

Applications

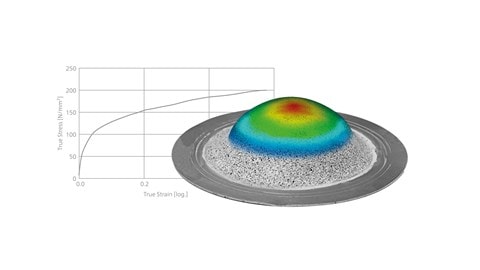

Surface strain measurement of samples

Non-contact and material-independent measurements based on the principle of digital image correlation (DIC).

Determination of material properties

For material tests such as Nakajima, bulge, tensile, bending, shear, and hole expansiontests.

GOM Acceptance Test

Evidence of the quality and performance capability of most ARAMIS sensors is provided by the GOM Acceptance Test (GAT). The acceptance procedure is based on VDI standards 2634-1 and 2626 and is an integral part of the outbound delivery process. Customers receive a GAT certificate for the purchased sensor, a DAkkS certificate for the optical scale used and a detailed process description.

Services

GOM keeps supporting its customers after the purchase and installation of 3D measuring systems.