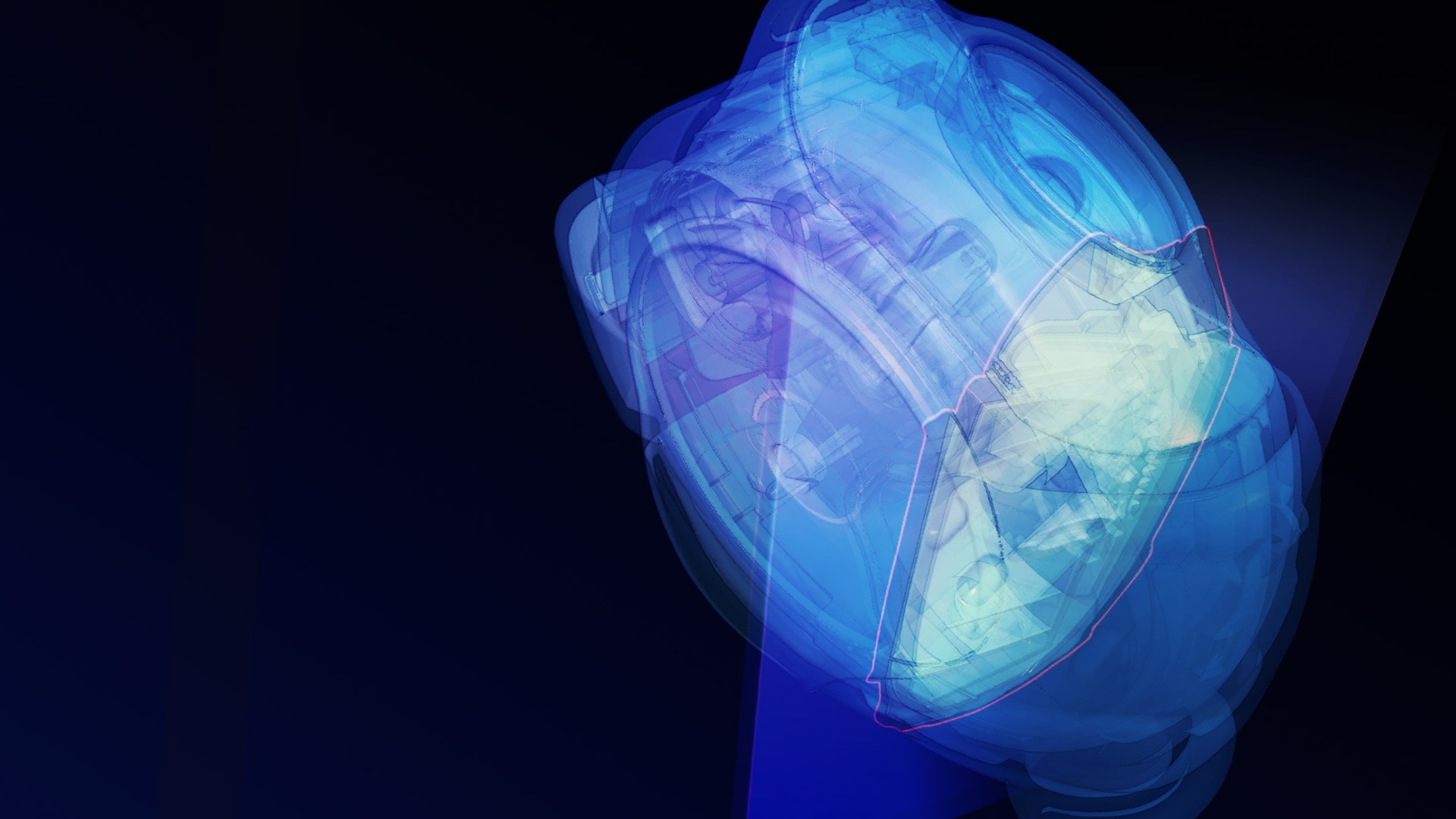

3D Computed Tomography

Reveal what remains hidden under the surface

The industrial use of CT systems offers a significant advantage: The digitization of complex parts includes the internal geometries at the finest level of detail. At the same time, the technology is very efficient as you can measure multiple parts in one scan. CT solutions include hardware such as ZEISS METROTOM series and an easy to use software for the entire workflow like GOM Volume Inspect Pro.

CT hardware

ZEISS Computed Tomography

A CT system supports the inspection of your parts in the development process and during production. The X-ray technology provides insights into your parts without destroying it. Find out about industrial CT systems from ZEISS.

CT software

GOM Volume Inspect Pro

GOM Volume Inspect Pro combines powerful 2D and 3D volume features with innovative measuring tools. The standalone software offers full analysis power for any computed tomography system. Look into the benefits and features of our CT software.

GOM Volume Inspect – the all-in-one software for CT data

Benefit from a complete workflow solution with ZEISS METROTOM 1 or ZEISS METROTOM 6 scout. GOM Volume Inspect combines the control of the device and the metrological evaluation of the data in a single software package, making additional software or intermediate steps redundant. The process chain from the recording of the raw data through the inspection up to the creation of a measuring report is significantly simplified.

Application solution

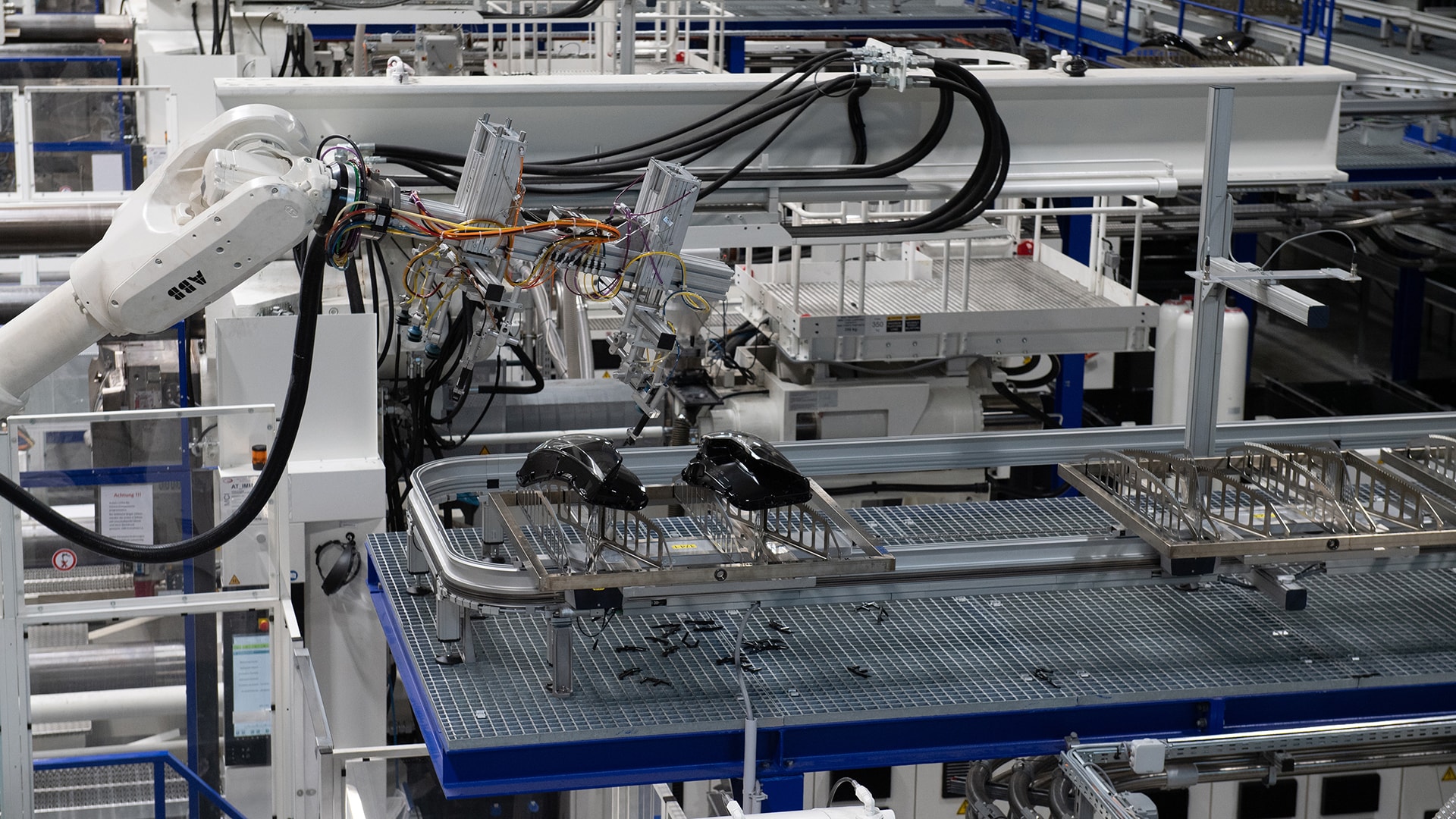

ZKW Lighting Systems in Austria uses ZEISS computer tomography and GOM software as a powerful overall solution for quality assurance of innovative, high-quality lighting systems for the automotive industry. The non-destructive measurement and testing quickly delivers comprehensive findings for ZKW. This saves development time and enables stable production processes.