- 3D measurement

- Scanning dimensions and geometries

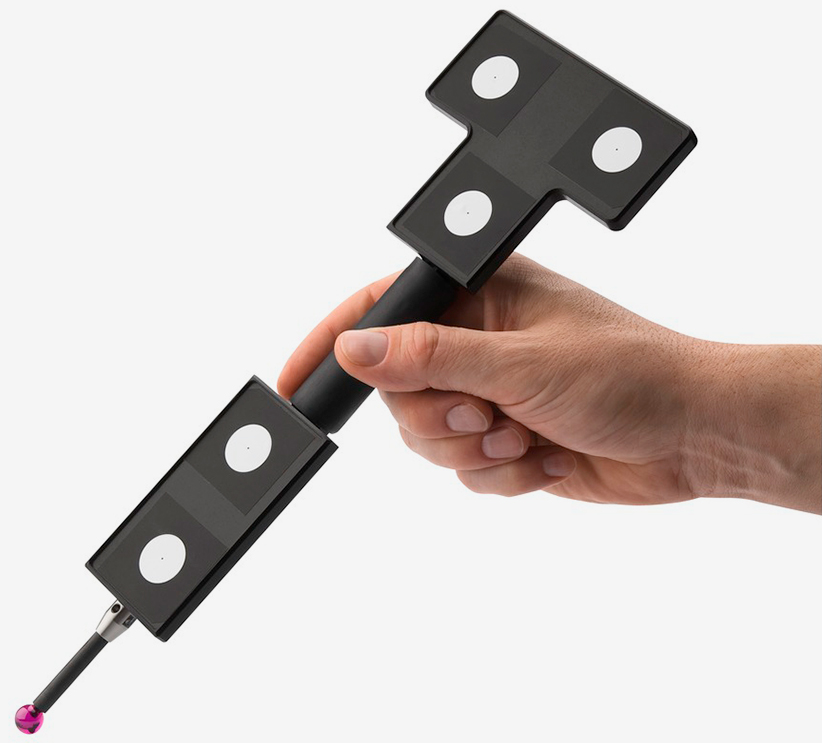

GOM Touch Probe

Combination of full-field and tactile measurements

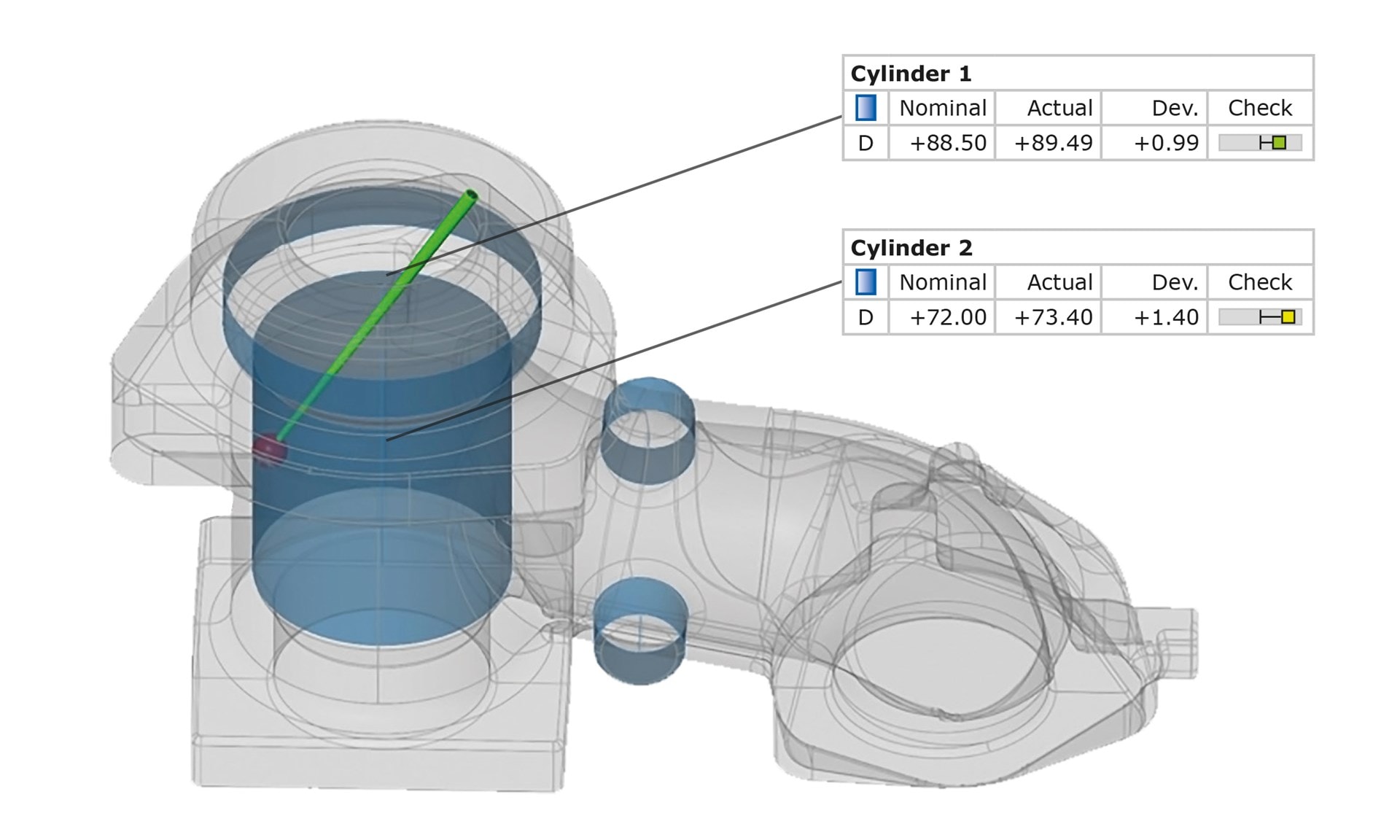

Many complex measuring tasks require a combination of full-field and tactile 3D measurements. The GOM Touch Probe is available as an accessory and incorporates a group of calibrated point markers that are optically tracked by the ATOS 3D digitizer. ATOS generates a 3D polygon mesh that exactly represents the object surface and the 3D coordinates captured with the GOM Touch Probe.

Benefits

- Full-field and tactile measurement

- Measurement of hidden areas that can hardly be captured by optical systems

- Evaluation of measuring data

- Comparison against CAD data

- Standard geometries

- Measurement of lines, planes, circles, cylinders and cones

- Freeform surfaces

- Quick measurement of individual points

- Online alignment

- Real-time motion tracking

Complete hardware and software

The lightweight GOM Touch Probe allows for easy measurement of large measuring projects over a longer period. Neither internal electronics nor cables are used, which guarantees high stability and mobility.

Both, the ATOS and touch probe measurements use the same software package to evaluate the results and do not require any additional hardware or tracker. As a result, measurements can be performed quickly and it is easy to switch between full-field and tactile measurement or measurement analysis.

Small to large objects

The GOM Touch Probe comes with five probe heads in different sizes, suitable for small to large objects. It was designed in a way that it is adaptable for various applications. The user can not only easily exchange the probe heads and extensions but can also construct customized touch probes for specific measuring tasks. For this reason, the GOM Touch Probe is suited to measure alignment holes of small injection-molded parts as well as cooling ducts of large casting molds.

Online measurement

The GOM Touch Probe and CMM adapters extend the possibilities of measuring geometrical elements online using ATOS sensors. For this purpose, the sensor continuously captures and tracks the movements of the optically tracked accessory. The software provides the user with constant feedback about the current position. The measurement is triggered manually, and only the measured value is saved in the software.

Applications

- Part alignment

- Preparation of the process

- Adjusting fixtures

- Further processing

- Trimming and springback

- Evaluation

- Quick online measurement

- Standard geometries and edges