ScanBox 8系

ATOS ScanBox 8系

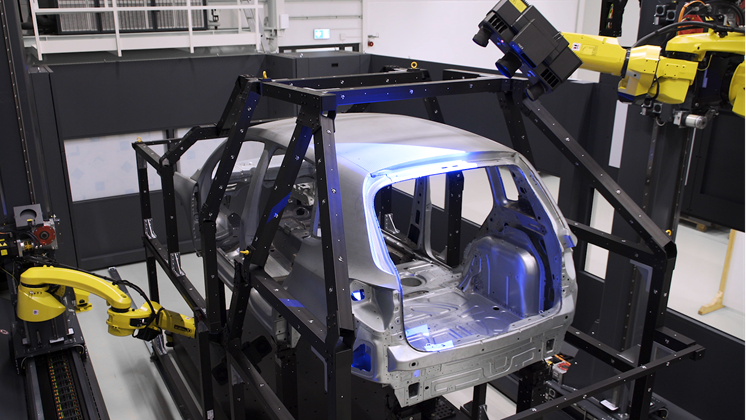

专为大型部件设计的ATOS ScanBox 8系是一套针对车身外部和内部进行快速数字化处理的整车测量系统。作为一套可执行车身测量和匹配分析、整车检测、实现车身制造质量控制的完整解决方案,这一模块化的测量单元受到了主机厂的广泛认可。 ATOS ScanBox 8系具有广泛的应用, 结合功能强大的GOM Inspect Pro软件,可以对多个零件的测量结果进行虚拟整合,对齐平和缝隙的细节信息进行线性评估。

双机器人自动扫描

两个8轴运动系统可对超大型组件进行全场测量。复式运行机制确保同步协调测量间里的两台机器人。在测量过程中,两台机器人始终处于同一坐标系下,系统会为其创建合并测量数据集。根据需求,两个机器人还可以分别对两个不同的零部件进行独立测量。

此外,ATOS ScanBox 8系还支持向外扩展一或两个旋转台工作区,以满足特定需求。升级之后的系统可以更灵活、更快速地响应生产变化并提高产量。

ATOS ScanBox 8160

该型号配备两个高速工业测头,可测量尺寸最大至6000 x 2500 mm的超重型零件。

ATOS ScanBox 8260

该型号支持双工位测量。可在中央区域测量车身的同时,于左侧或右侧的旋转台区域检测例如车门、引擎盖等汽车附件。

ATOS ScanBox 8360

该型号配配备两个可独立操作的旋转台工作区,可以快速获得准确的测量结果,用于后续分析,是ATOS ScanBox 8系的最高拓展形态。

Car body measuring technology: Flexible. Fast. User-friendly.

Accelerated measurement and inspection of body-in-white

The new reference frame for ATOS ScanBox Series 8 makes production control in series even more efficient. The flexible system is ready to go without any preparation time. You can significantly increase your throughputs. Inspect more than 1000 measurement features, such as surface and edge points, holes and bolts. Measurement results can be easily exported to a statistical database.

灵活的装载方式

ATOS ScanBox 8系可以经由轨道系统、驱动计算机和安全系统组成的无人驾驶的夹芯板运输系统进行装载。这种自动装载系统可以确保车身的快速、可重复、精确定位。此外还通过运输车、托盘车、起重机或叉车将零件运输到相应的旋转台工作区。

Digital Vehicle Audit of Finished Car Bodies

Today, the visual impression of new vehicles is more important than ever – OEMs focus a lot on an aesthetic gap pattern as well as flawless surfaces during production. During the final inspection of the vehicle, each new model should be inspected comprehensively – but there is often not enough time to open all the flaps and carefully digitize the edges. For this demand, GOM Inspect Pro provides a new feature.

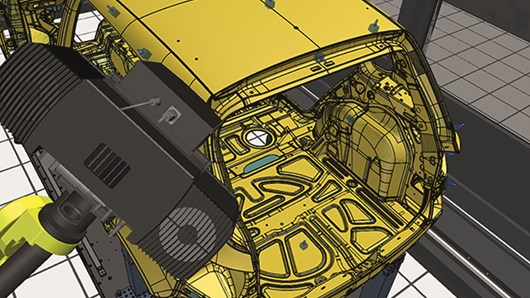

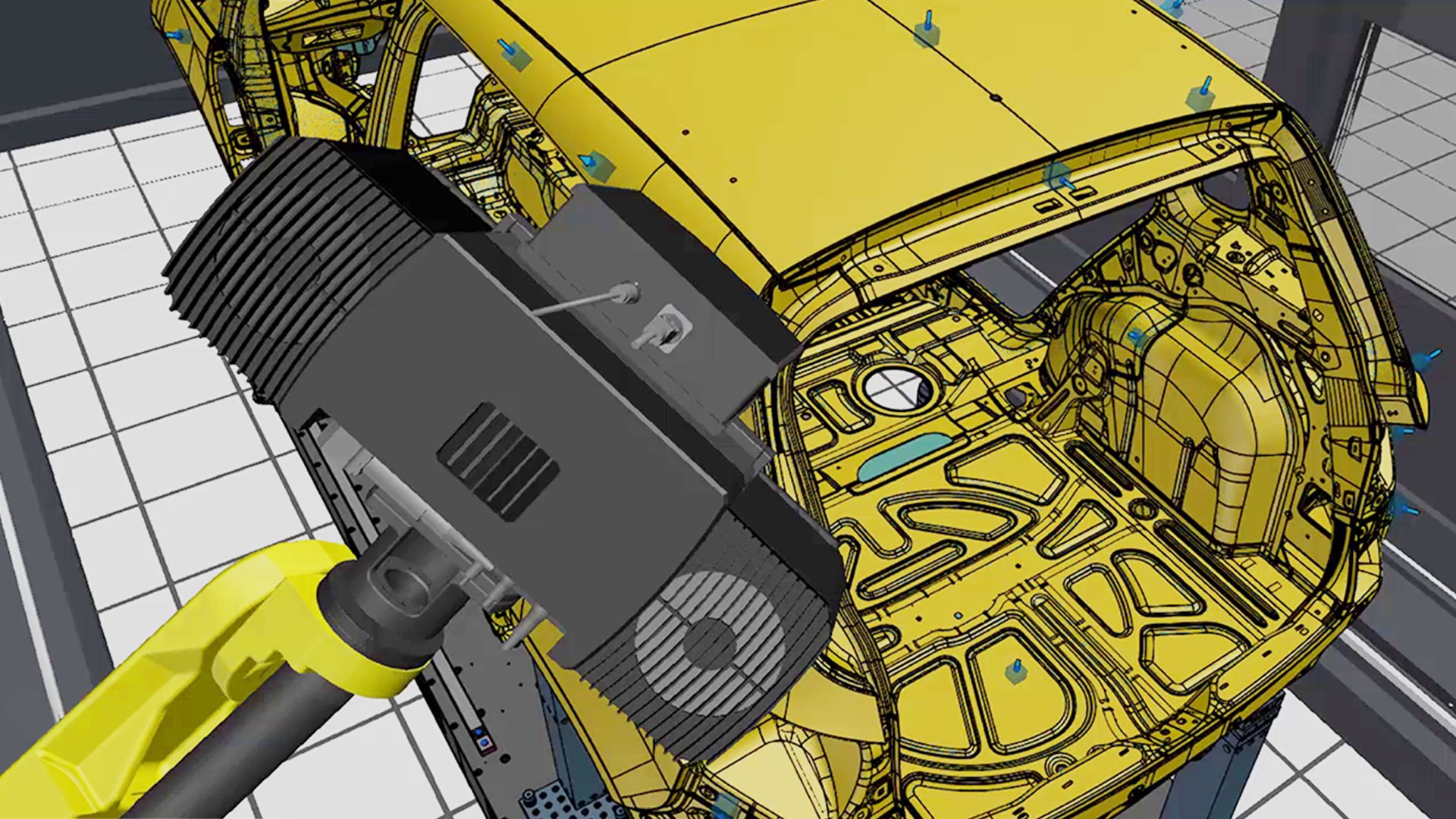

GOM Inspect Pro 中的虚拟测量室

虚拟测量室(VMR)是ATOS测量单元所有元素的中央控制站和测量计划软件。在VMR中,真实环境,即测量单元中的机器人、传感器和零件,在模拟中进行功能模拟。编程包括运动学、机器人路径、零件夹具和测量计划。由于VMR,用户可以使用该系统,而不需要特定的机器人编程技能。所有的机器人运动都是模拟的,并在实际环境中进行安全检查。

测头兼容性

ATOS 测头为每次测量提供全场三维坐标。单次扫描即可捕获多达1200万个独立测量点,过程仅需数秒。因此,测量数据细节重现度极高,可以摄取到极小的组件特征。

技术参数

| ATOS ScanBox 8160 | ATOS ScanBox 8260 | ATOS ScanBox 8360 |

|

| 尺寸 | 5750 × 10150 × 3900 mm | 9750 × 10150 × 3900 mm | 13750 × 10150 × 3900 mm |

| 电源 | 2× 200–500 V (3-相, 32 A) | 2× 200–500 V (3-相, 32 A) | 2× 200–500 V (3-相, 32 A) |

| 最大零件尺寸 | 6000 × 2500 mm | 6000 × 2500 mm, 转台区最大零件尺寸 Ø 3000 mm | 6000 × 2500 mm, 转台区最大零件尺寸 Ø 3000 mm |

| 最大零件重量 | 不限 | 不限,转台区最大零件重量2000 kg | 不限,转台区最大零件重量2000 kg |

| 出入口 | 安全光帘 | 安全光帘 | 安全光帘 |

| 开口宽度 | 3050 mm | 3050 mm, 转台区最大零件尺寸 3400 mm | 3050 mm, 转台区最大零件尺寸 3400 mm |

| 是否需要地面安装或固定 | 需要 | 需要 | 需要 |

| 装载方式 | 手动装载或运输车、托盘车、起重机、叉车、夹芯板运输系统装载 | 手动装载或运输车、托盘车、起重机、叉车夹、芯板运输系统装载 | 手动装载或运输车、托盘车、起重机、叉车夹、芯板运输系统装载 |

| 兼容测头 | ATOS 5, ATOS 5X | ATOS 5, ATOS 5X | ATOS 5, ATOS 5X |