ScanBox Series 8

Two-Sides Measurement of Long and Wide Parts

This 3D measuring machine is designed for something big: With ATOS ScanBox Series 8, complete vehicles are digitized at high speed, both from the outside and the inside. The modular measuring cell has established itself among OEMs as a complete solution for analyses in Meisterbock and Cubing, the inspection of finished vehicles, and for quality assurance in car body manufacturing. Take advantage of the wide range of possibilities of ATOS ScanBox Series 8 : Virtually merge measurements of multiple parts and use the powerful GOM Inspect Pro software for linear evaluation of detailed information on gap and flush.

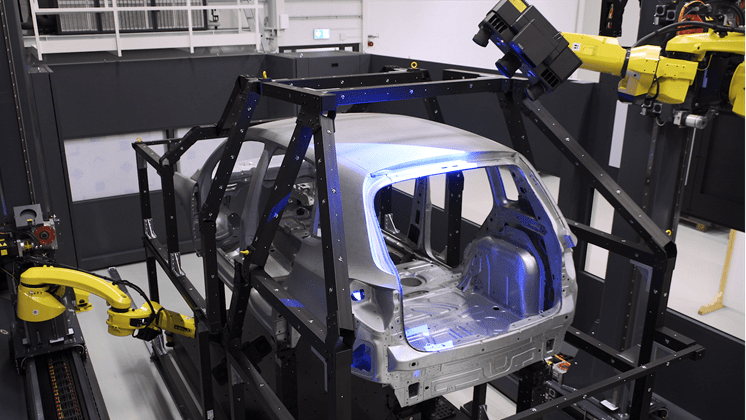

Automated Scanning in Double Robot Mode

Two 8-axis kinematics allow for full-field measurement of particularly large assemblies. The duplex mode ensures synchronous, coordinated use of two robots in the measuring cell. In this process, a joint data set of measurements is created, as the double robot mode takes place in a shared coordinate system. Depending on your needs, the two robots of ATOS ScanBox Series 8 can also be used for independent measurement on two different parts.

Depending on the specific requirements, ATOS ScanBox Series 8 can be extended by one or two rotation table working areas. With this upgrade, you can respond even more flexibly and quickly to production changes and increase throughput.

ATOS ScanBox 8160

In the measuring cell, you use two high-speed sensors to measure particularly heavy parts with a maximum size of 6000 x 2500 mm.

ATOS ScanBox 8260

While a car body is being measured in the central working area, you can inspect add-on parts, such as doors or trunk lids, in the left or right rotation table working area.

ATOS ScanBox 8360

Get the best out of ATOS ScanBox Series 8: With two additional rotation table working areas that can be operated independently from each other, you get fast and precise measuring results for your analyses.

Car body measuring technology: Flexible. Fast. User-friendly.

Accelerated measurement and inspection of body-in-white

The new reference frame for ATOS ScanBox Series 8 makes production control in series even more efficient. The flexible system is ready to go without any preparation time. You can significantly increase your throughputs. Inspect more than 1000 measurement features, such as surface and edge points, holes and bolts. Measurement results can be easily exported to a statistical database.

Flexible Loading Options

ATOS ScanBox Series 8 can be loaded with a driverless sandwich panel transport system including a track system, drive computer and safety systems. The automated loading system guarantees fast, repeatable and accurate positioning of car bodies within ATOS ScanBox. Alternatively, the parts can also be transported to the respective rotation table working area by transport cart, pallet truck, crane or forklift truck.

Digital Vehicle Audit of Finished Car Bodies

Today, the visual impression of new vehicles is more important than ever – OEMs focus a lot on an aesthetic gap pattern as well as flawless surfaces during production. During the final inspection of the vehicle, each new model should be inspected comprehensively – but there is often not enough time to open all the flaps and carefully digitize the edges. For this demand, GOM Inspect Pro provides a new feature.

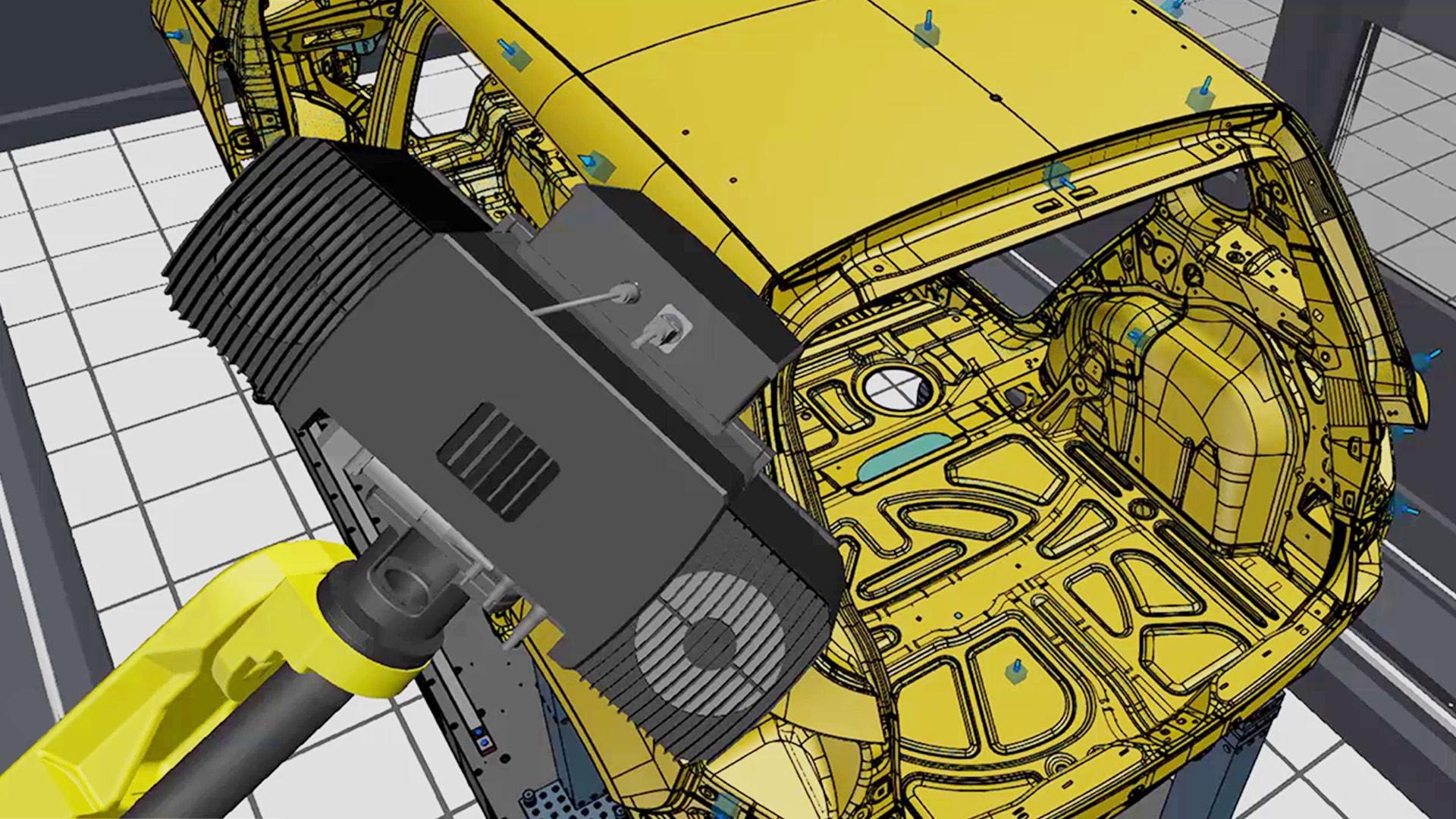

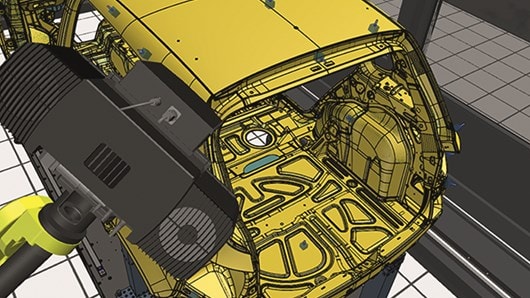

Virtual Measuring Room in GOM Inspect Pro

The virtual measuring room (VMR) is the central control station and measurement planning software for all elements of the ATOS measuring cells. In the VMR, the real environment, i.e. robots, sensors and parts in the measurement cell, is functionally simulated in a simulation. The programming includes the kinematics, the robot paths, the part fixture and the measurement plan. Thanks to the VMR, the user can work with the system without requiring specific robot programming skills. All robot movements are simulated and checked for safety before being performed in the actual environment.

Sensor Compatibility

ATOS sensors provide full-field 3D coordinates for each individual measurement. Within a few seconds, up to 12 million independent measuring points are captured per scan. As a result, the measuring data are characterized by a high detail reproduction, which enables you to also measure very small parts.

Technical Information

| ATOS ScanBox 8160 | ATOS ScanBox 8260 | ATOS ScanBox 8360 |

|

| Dimensions | 5750 × 10150 × 3900 mm | 9750 × 10150 × 3900 mm | 13750 × 10150 × 3900 mm |

| Power supply | 2× 200–500 V (3-phase, 32 A) | 2× 200–500 V (3-phase, 32 A) | 2× 200–500 V (3-phase, 32 A) |

| Max. part size | 6000 × 2500 mm | 6000 × 2500 mm, rotation table working area up to Ø 3000 mm | 6000 × 2500 mm, rotation table working area up to Ø 3000 mm |

| Max. part weight | Unlimited | Unlimited, rotation table working area up to 2000 kg | Unlimited, rotation table area up to 2000 kg |

| Entry | Safety light curtain | Safety light curtains | Safety light curtains |

| Opening width | 3050 mm | 3050 mm, rotation table working area up to 3400 mm | 3050 mm, rotation table working area up to 3400 mm |

| Floor mounting or fixing | Required | Required | Required |

| Loading concept | Manual, transport cart, pallet truck, crane, forklift truck, sandwich panel transport system | Manual, transport cart, pallet truck, crane, forklift truck, sandwich panel transport system | Manual, transport cart, pallet truck, crane, forklift truck, sandwich panel transport system |

| Sensor compatibility | ATOS 5, ATOS 5X | ATOS 5, ATOS 5X | ATOS 5, ATOS 5X |

Services

Our service range after the purchase and installation of 3D measuring systems.

-

GOM Care

Support and services on a contractual basis for all 3D measuring systems from GOM Metrology.

-

GOM Training – Automation VMR

In this two-day training, you will get to know the complete process for the creation and execution of automation projects from scratch to the final mesh.

-

GOM Training – eLearning: Robogrammetry – Measuring Large Objects in ATOS ScanBox Series 7 and 8

This eLearning guides you step by step through the complete process of robogrammetry and shows how to prepare, use and optimize robogrammetry in the GOM software and at ATOS ScanBox.