ZEISS ScanCobot

The perfect combination for simple automated inspections tasks

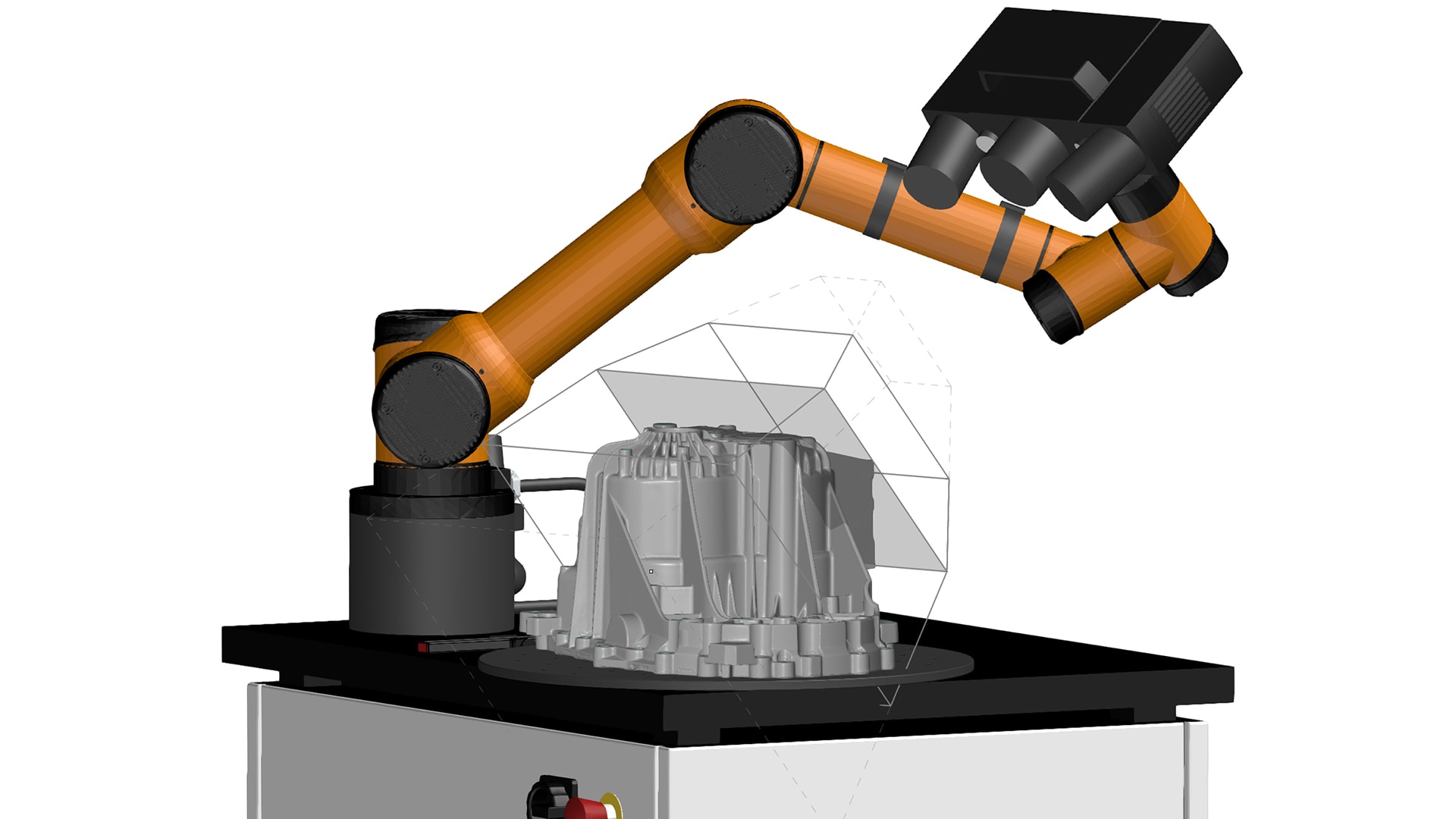

ZEISS ScanCobot is a mobile measuring station with a collaborative robot, a motorized rotation table and powerful software. It is especially suited for efficient quality control of small and medium-sized parts made of plastic, metal or cast iron. The system can be used during the preproduction phase such as design and prototyping and during the market launch. In a short measuring time, the optical 3D scanner ATOS Q captures quality information at a high level of detail, providing a reliable basis for easy interpretation. To measure a part completely, the sensor must face the part from different directions. The ZEISS ScanCobot uses a collaborative robot to perform this normally manual work process. Combined with the motorized rotation table, the robot can move along the sensor positions very quickly one by one. Efficient scanning and subsequent automatic inspection speed up quality control processes.

Easy Robot Programming in the Virtual Measuring Room

The ZEISS ScanCobot is programmed in the virtual measuring room (VMR). The VMR is the central control and measurement planning software that represents the complete measuring procedure. In the software, the CAD data set of the part to be inspected is imported together with the associated measurement plan. The necessary sensor positions and robot paths are computed fully automatically at the push of a button.

The Smart Teach functionality allows the user to work with the system without the need for specific robot programming skills. If the Kiosk Interface is activated, parts can be measured quickly using existing project templates, without the need for adjustments. As the user can no longer change measuring programs and evaluations, process reliability is enhanced. With the ZEISS ScanCobot, measuring and inspection tasks can be easily delegated from the measuring room to production.

ATOS Q – High-speed 3D scanner with superior data quality

Technical Information and Safety

ZEISS ScanCobot is a mobile measuring station that can easily and quickly be moved from one location to another. Only a standard socket is required for commissioning. The system can be equipped with a standardized safety housing to comply with market-specific safety regulations.

| Dimensions footprint [mm] | 975 x 775 |

| Working height [mm] | 1000 |

| Power supply |

Standard, 100–240 V (1-phase, 16A) |

| Max. part size [diameter in mm] |

500 |

| Max. part weight [kg] |

50 |

| Sensor compatibility |

ATOS Q |

Services

GOM keeps supporting its customers after the purchase and installation of 3D measuring systems.