High Precision 3D Metrology

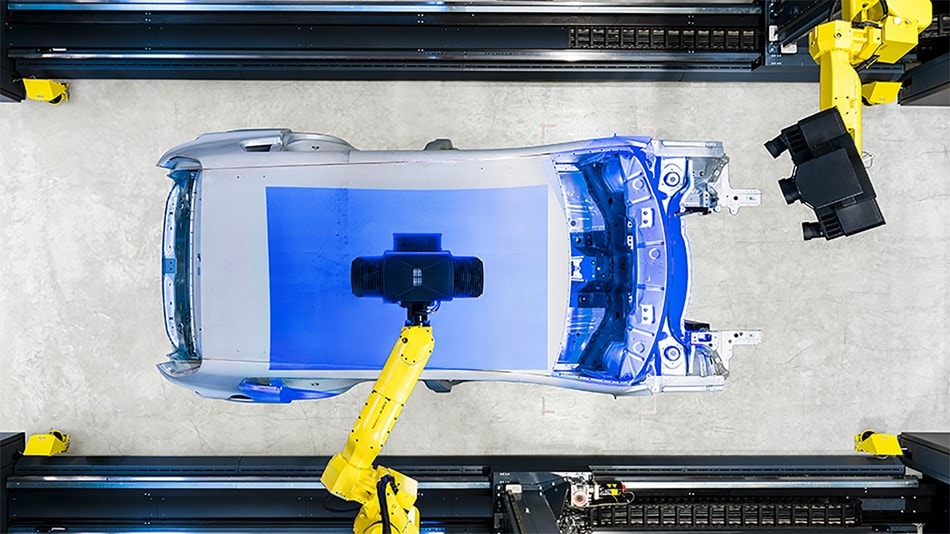

Industrial 3D Measuring Systems with High-Speed Technology

GOM internationally sets standards in optical 3D metrology. ATOS sensors help customers worldwide to increase product quality, optimize processes and thus produce more efficiently.

ATOS 3D scanners are high-resolution optical digitizers, delivering three-dimensional measuring data quickly and precisely. ATOS was developed with advanced hardware and intelligent software for repeatable and precise measurements. The measuring systems work non-contact by using structured blue light and deliver precise scans with detailed resolution at high speed.

ATOS systems are used in many industries for the inspection of parts such as sheet metals, tools and molds, turbine blades, prototypes and injection-molded and pressure die-cast parts.

ZEISS ATOS LRX

Fast, Full-Field Data Acquisition of Large Measuring Areas

With an ultra-bright laser light source and a large measuring area of up to 4 square meters, ZEISS ATOS LRX delivers precise, full-field data in short time. The sensor captures up to 2 x 12 million coordinate points with just one scan.

ATOS 5

High-speed 3D scanning

Developed for industrial use, ATOS 5 delivers high-precision 3D data in a short measuring time − even under harsh conditions. The enhanced measuring areas combined with high resolution result in faster processes thanks to few measurements.

ATOS 5X

3D scanning with large measuring areas

With its powerful light source, ATOS 5X enables the use of large measuring volumes for maximum speed in automated applications. The integrated Laser Light Compressor generates ultra-bright light, thus enabling very short exposure times.

ATOS 5 for Airfoil

Tailor-made for gas turbine industries

Developed for gas turbine industries, ATOS 5 for Airfoil with its optimized working distance and measuring areas from 100 x 70 mm² delivers high-precision 3D data of the smallest details in a short measuring time.

PONTOS Live

3D measuring system for online photogrammetry

PONTOS Live is the tracking system from GOM for part positioning. The system is used for the precise part positioning on CNC machines or for the adjustment of fixtures. Combined with the GOM Touch Probe, PONTOS Live allows the inspection of areas that are optically difficult to access.

Further Products of the ATOS Family

ATOS Technology

Dynamic Referencing

The proven stereo camera principle of ATOS delivers an overdetermined system of equations for every measurement. The combination of the stereo camera principle with GOM’s Reference Point System guarantees the process reliability of ATOS by:

- Detection of sensor and part movements

- Verification of measuring accuracy and quality

- Identification of environmental changes

- Tracking of 3D sensor position

Triple Scan Principle

Precise fringe patterns are projected onto the surface of the object and are captured by two cameras based on the stereo camera principle. As the beam paths of both cameras and the projector are calibrated and therefore known in advance, 3D surface points from three different ray intersections can be calculated. This Triple Scan Principle offers advantages for measuring reflective surfaces and objects with indentations. The result is complete measuring data without holes or erratic points.

Blue Light Equalizer

GOM’s projection technology works with narrow-band blue light, which means that interfering ambient light can be filtered out during image acquisition. In addition, ATOS 5 is equipped with a Blue Light Equalizer, which increases the brightness of the light source by a factor of 1.5 and transmits uniform, non-coherent, speckle-free light to the projection unit.

The Blue Light Equalizer of ATOS 5 is so powerful that even on unconventional surfaces short measuring times can be achieved and the precise coverage of complex geometries is possible.

Laser Light Compressor

The light processing of the ATOS 5X is extended by a Laser Light Compressor, which bundles several laser elements to generate an extremely bright light source based on laser light. The up to eight times brighter light is especially resistant to ambient light influences and enables measuring areas of up to 1,000 mm and extremely short exposure times. This reduces the number of required scans, simplifies the measuring setup and shortens the measuring time.

Blue Light Technology

GOM’s projection technology works with narrow-band blue light, which means that interfering ambient light can be filtered out during image acquisition. The light sources are so powerful that even on non-cooperative surfaces measuring data is captured. In addition, the LEDs of the Blue Light Technology have a life expectancy of far more than 10,000 hours.

Services

GOM keeps supporting its customers after the purchase and installation of 3D measuring systems.