Buderus Guss: Sustainable Production of Brake Disks Made in Germany

Buderus Guss: Sustainable Production of Brake Disks Made in Germany

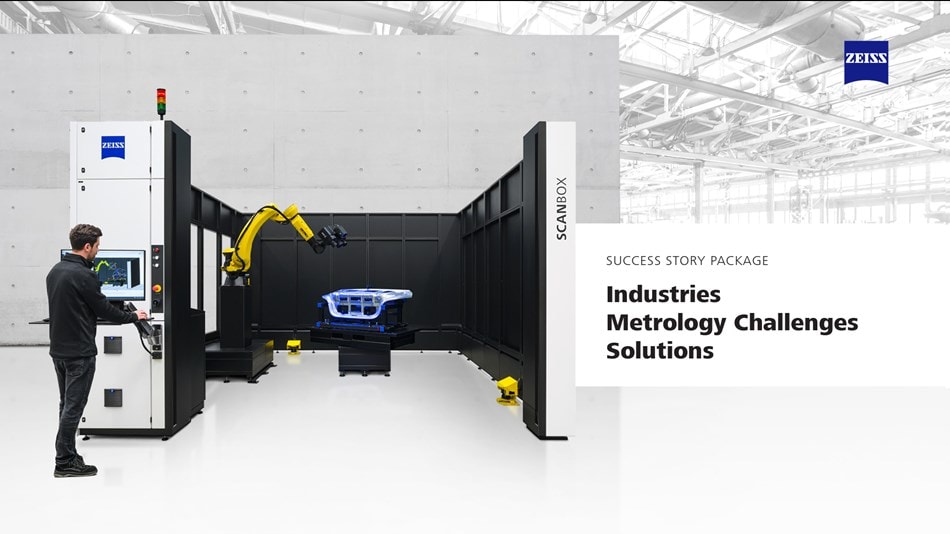

At its site in Breidenbach, Germany, automotive supplier Buderus Guss annually produces around 15 million brake disks for passenger cars. For manufacturing its parts, the European market leader uses both industrial scrap and recycled materials from its own production, thus offering to its customers a safety-related and sustainably produced product. The automated quality assurance is conducted by a ScanBox Series 4 during production. The compact optical measuring machine is capable of inspecting up to 190 brake disks per day. If it finds deviations, it transmits the generated measuring data to production in real time to allow for adjusting process parameters.

Environmental protection and cost efficiency go hand in hand

With its products, processes and knowhow, Buderus Guss committed itself to the goals of sustainability and resource efficiency. Environmental protection is a fixed part of the company’s code of conduct and rated as important as the quality of the brake disks and cost-efficient entrepreneurship. Each brake disk manufactured in the plant is 100% recyclable. The disks are supplied to all German OEMs and many international automotive manufacturers. To be able to meet the high demand, melting more than 1,000 tons of liquid iron per day is required.

Quality control during three-shift production

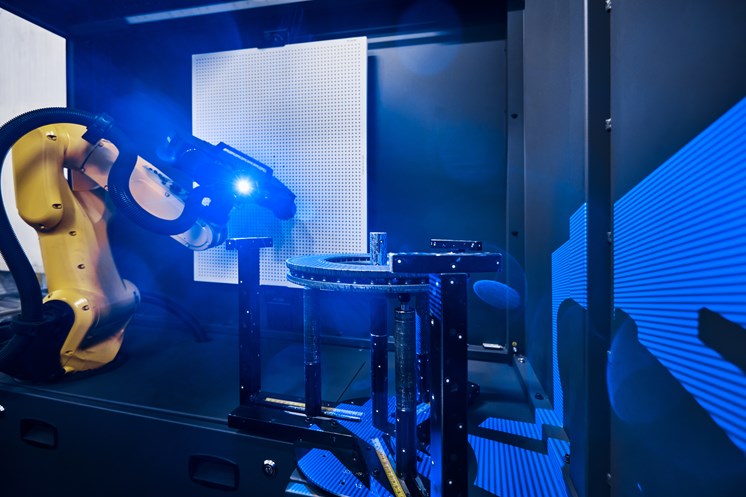

When the casting into the sand moldings is completed, the safety-related parts are inspected for dimensional accuracy. “In terms of solidity, the final brake disk must comply with the specifications,” explains Steffen Sasse, Casting Manager at Buderus Guss. Once fitted, only a minor deformation of the brake disk is permitted. Since it is exposed to extreme strain with temperatures of up to 700 degrees Celsius during the braking process, Buderus Guss produces ventilated brake disks that discharge the heat from inside the part via the ventilation duct to the outside. Deviations, if any, and resultant quality losses are restricted by previously defined tolerances. These specify which deviations from the nominal are permitted – and when the brake disk is deemed Not Okay (NOK) and therefore unfit for use without any post-processing. The data for comparison are created with a ScanBox Series 4 optical measuring machine during three-shift production. “With the ScanBox, we are able to digitize an entire part in no time and to determine various drawing dimensions afterwards by creating GD&T as well as sections or false color comparisons,” explains Marcel Nickel, Optical Metrology Specialist at Buderus Guss. Thus, precise and retraceable measuring results allow for a quick first article inspection.

Marcel Nickel is particularly convinced by the easy handling of the ScanBox system – the intuitive Kiosk Interface makes it possible to fully digitize a part at the push of a button. The metrologist is very pleased with the ScanBox system: “I am fascinated by the dimensional accuracy with which we can produce a casting part. Moreover, the inspection during production shows us that our process is stable and that we generate almost no scrap.”

Buderus Guss

As a partner of the international automotive industry for the development and manufacturer of car brake disks, Buderus Guss is globally positioned.

From 1991, the Breidenbach location in Hessen was consistently expanded to specialize in brake parts. Since 2016, the Ludwigshütte location has been the technology center for developing and production of the innovative, fine dust reducing brake disk iDisc®.

Buderus Guss stands for high-quality materials, state-of-the-art production processes, excellent quality, safety and perfection with tradition. We supply all well-known car manufacturers in Europe as well as customers in Japan and South Korea with car brake disks for both original equipment and original spare parts service.

Since 2005, Buderus Guss GmbH has been a company of Robert Bosch GmbH and is now part of to the Chassis Systems Control.

Since 2017, Robert Bosch Lollar Guss GmbH has been a cooperation partner of Buderus Guss and mainly produces car brake disks of large dimensions in an extended state-of-the-art foundry Lollar/Hessen site. The Breidenbach, Ludwigshütte and Lollar locations are combined in the Bosch CC-BC product division.