- Fast

- troubleshooting

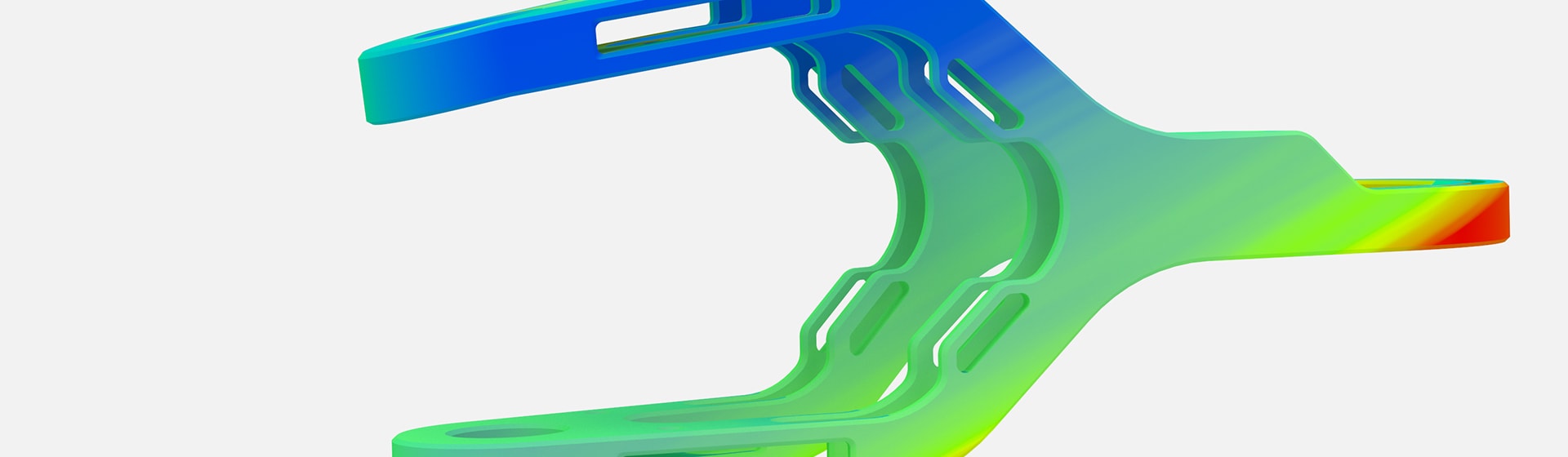

Measuring part distortions

Measuring part distortions caused by heat treatment and removal from the build plate

The challenge

3D printed parts are subjected to several heat treatments. These include tempering and HIPing. The heat treatments reduce the stresses in the part, increase its density and help to achieve the final form and surface.

These types of heat treatment, along with other steps in the additive manufacturing process, such as removing the part from the build plate, can have an impact on the part’s dimensions. And if the dimension deviations in the final part are not within the desired tolerances, finding out where exactly in the process the deviations occurred is a challenge. To locate the problem, the deviations must be analyzed during the individual process steps.

The solution

The ATOS system lets you digitize the part efficiently between the various process steps so that you can track the deformations that occur, for example before and after heat treatment and after removing the part from the build plate. This makes it possible to check precisely how much deformation takes place through internal stresses and at which stage of the process it occurs.

In the GOM Inspect software, users can compare the actual data from the various process steps with each other or with the target data. As a result, changes can be closely monitored throughout the entire process. And comparisons with the CAD model can be carried out at any time.

The results of these measurements can be used to optimize the process efficiently by adjusting the process parameter settings. Trend analyses show you how the 3D printed parts change over time.

The benefits

- Full-field measurements

- to check parts for distortions in various process steps

- Trend analysis

- and statistical process control