- High speed

- 0.2 seconds per measurement and 100 frames per second

- Robust precision

- Housing protected from dust and splash water

ATOS 5

La précision par l'innovation

Développé pour l'industrie, ATOS 5 fournit des données de haute précision en un temps de mesure très court, même dans des conditions extrêmes. Les données de mesure 3D plein champ permettent de réaliser des opérations exhaustives de contrôle de la qualité et du processus grâce à la visualisation des erreurs dissimulées, permettant ainsi d'accélérer les opérations de production.

ATOS 5 Accelerates Production Processes

ATOS 5 meets the high metrological requirements of industrial users. The system provides high-precision data: from tools and molds to plastic and metal parts. The inspection software GOM Inspect Pro guides you through the entire workflow, from measurement and evaluation to the inspection report. The full-field 3D scans enable comprehensive process and quality control by making errors and defects visible. This allows for early corrective measures to be taken and fast process optimization.

Fast

- Up to 50% faster when inspecting

- Short exposure times, even with shiny and dark surfaces

- Maximum speed due to enlarged measuring areas

User-friendly software

- Complete package for measurement, evaluation and reporting

- Digital twin for inspection, adaptive manufacturing, simulation and reverse engineering

- Detailed 3D models (rib structures, narrow radii or hemmed edges)

Robust

- Developed for industrial use

- Self-monitoring systems

- Fast and interference-free data transmission

Flexible

- Variable systems for individual requirements

- Stationary, mobile, automated

- Production environment and measuring room

Graphics Card Accelerates Measurements

Thanks to its GPU acceleration, ATOS 5 provides fast measuring results. The GOM Inspect software uses the computing power of the graphics card. Due to the large number of cores on the GPU, individual scans are processed faster. This significantly reduces the total measuring time. Combined with its powerful light source and camera technology, ATOS 5 reaches a new level of performance with this GPU acceleration.

Designed for a Wide Range of Tasks

Companies from the automotive, consumer goods and aerospace industries are successfully using ATOS 5 to accelerate time-to-market and maintenance of products and to ensure the quality in ongoing production, thus minimizing the costs. The sensors ensure the quality of sheet metals, tools and molds, turbine blades, prototypes as well as injection-molded and cast parts. The software guides the user through the entire workflow.

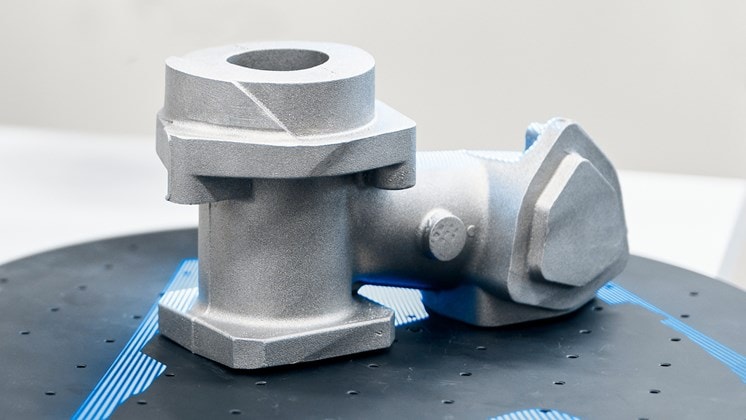

Casting and forging

In sand, pressure die and investment casting processes as well as in the forging industry, ATOS 5 is used for consistent quality assurance: from simulation validation to acceleration of tool try-out and first article inspection to production control and CNC machining.

The systems allow for inspection planning based on design data. In pattern and mold making, the targeted correction of tools and patterns and the inspection of fitting for mold halves, cores and sliders are possible. In tool try-out, cast parts are checked for shape and dimensional accuracy: part geometry, material thickness, shrinkage and warpage. For quality control during series production, measuring and evaluation processes are automated.

Plastics

ATOS 5 speeds up all phases of injection molding, blow molding and thermoforming by measuring complete surfaces of prototypes, electrodes, tools and injection-molded parts. The system also measures demanding freeform contours quickly and completely. The full-field measuring results guarantee a faster first article inspection and targeted tool correction, thereby reducing production lead times. For quality control in series production, both the measurement and the entire evaluation can run automated.

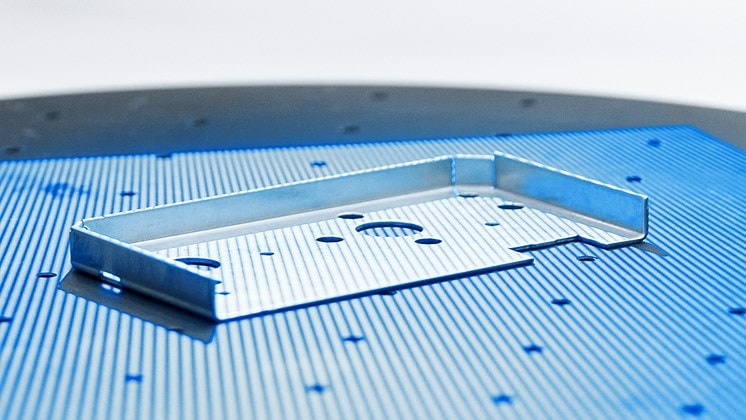

Metal forming

ATOS 5 is used in stamping, bending, drawing, pressing and forming process chains to guarantee consistent quality assurance: The 3D scanners help to optimize the design of parts and tools. They speed up tool try-out and first article inspection. In addition, ATOS 5 ensures efficient production control and assembly analysis during series production.

Additive manufacturing

In additive manufacturing, ATOS 5 accelerates product development and launch through fewer iterations and better process control while maintaining high product quality. The 3D scanners digitize the complete surface of additively manufactured parts and provide high-resolution polygon meshes (STL files). By comparing the measuring data with the design data in the inspection software from GOM, the dimensional quality of the parts can be checked, thus improving the CAD model. Furthermore, the data simplifies reverse engineering. The 3D point cloud created by ATOS 5 can be used as an STL file for direct 3D printing. In this way, time-consuming CAD data creation is no longer necessary for rapid prototyping in reverse engineering.

High-Speed 3D Scanning System for Industrial Demands

ATOS 5 captures up to 2 x 12 million coordinate points during scanning. Accuracy, resolution and the size of the measuring area can be defined freely. This also allows for a very high resolution in complex, detailed parts as well as very rapid digitizing of large parts.

- High detail resolution

- Projection of very small fringes per unit area

- Flexible measuring areas

- Changeable measuring volumes

- High data throughput

- Cable lengths up to 30 meters

- Blue Light Equalizer

- Bright light source with uniform, speckle-free light

Gamme de produits ATOS 5

Métrologie 3D industrielle avec technologie à grande vitesse

ZEISS ATOS LRX

ZEISS ATOS LRX

|

ATOS 5 for Airfoil

ATOS 5 for Airfoil

|

ATOS 5

ATOS 5

|

ATOS 5X

ATOS 5X

|

|

|---|---|---|---|---|

| Technical Data | ||||

| Your system for: | 3D scanning for very large volumes | precise scanning of smallest details | high-speed 3D scanning system | automated scanning for large volumes |

| Light source | LASER | LED | LED | LASER |

| Measuring points per scan | 12 m | 12 m | 8 or 12 m | 12 m |

| Working distance | 1810 mm | 530 mm | 880 mm | 880 mm |

| MORE | More | More |

Services

GOM assiste ses clients bien après l'achat et l'installation des systèmes de mesure 3D.