ZEISS ScanBox Series 5 RC

Contrôle de qualité relatif à la production et surveillance en série

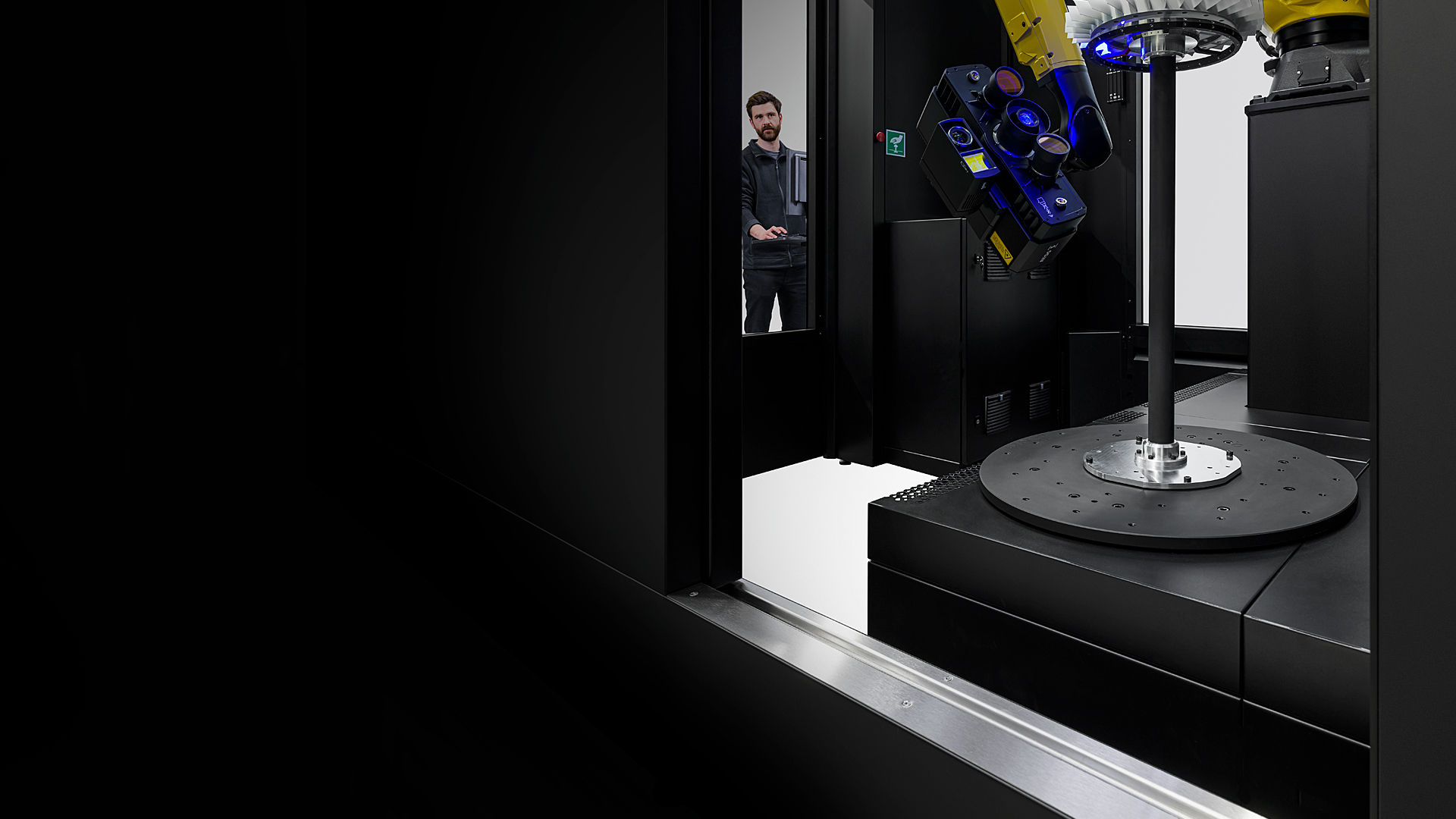

La ZEISS ScanBox Series 5 RC (Remote Control) est une machine de mesure 3D sans contact équipée d'une porte coulissante motorisée. Un robot ou un système de chargement personnalisé vous permet de charger automatiquement des composants de type pales, composants assemblés ou outils dans la ZEISS ScanBox Series 5 RC pour les placer sur le module plateau tournant. Puisque l'utilisateur n'a pas à placer chaque composant un par un, le temps que le contrôle qualité demande est nettement plus court qu'auparavant. Le fonctionnement autonome augmente les possibilités d'utilisation de la machine, accélère les cycles de mesure et favorise un déploiement plus efficace du personnel. La ZEISS ScanBox Series 5 RC est disponible en deux modèles et elle a été conçue spécialement pour les applications qui exigent un fort degré d'intégration et un débit élevé. Le système s'intègre facilement dans toute ligne de production grâce à son impact minime.

Débit élevé et grande répétabilité

Procédures de mesure précises et comparabilité optimale

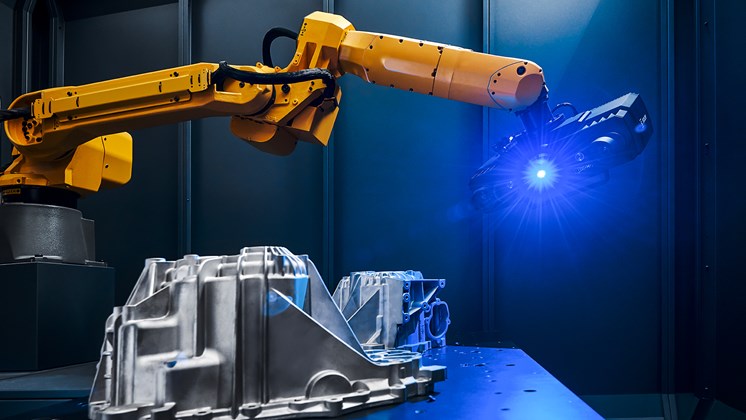

Le contrôle qualité pendant la production en série consiste à surveiller le processus de production, à réduire les chutes et les rectifications nécessaires. Pour cette application, la machine de mesure 3D sans contact ZEISS ScanBox Series 5 RC est la solution idéale. Comparer directement les coordonnées réelles de composants en série créés entièrement en 3D avec une tête de mesure ATOS 5, avec le modèle CAO ou des caractéristiques d'un plan de mesure. Créer des rapports de contrôle directement sur le site de production et les exporter vers des systèmes de contrôle statistiques de processus.

Utilisation maximum des machines et processus optimisés

Pour utiliser le potentiel complet de la ZEISS ScanBox Series 5 RC, combinez la machine de mesure 3D sans contact avec un système d'alimentation et de chargement ZEISS. La série ZEISS Integration vous permet d'automatiser le chargement des composants, et donc d'éviter des immobilisations de la machine. La circulation des composants et les durées de traitement sont optimisées.

Technologie d'automation avec un système de traitement par lots

L'intégration d'un système de traitement par lots augmente la durée de cycle et réduit les besoins en personnel car le système agit de manière autonome pendant jusqu'à 11 heures. Des lots de composants, de type pales de turbine, sont empilés dans le système de traitement par lots. Chaque emplacement est doté d'une puce RFID destinée à l'identification. Le programme de mesure correspondant est automatiquement sélectionné à partir de ces informations. Le composant est retourné automatiquement après le contrôle.

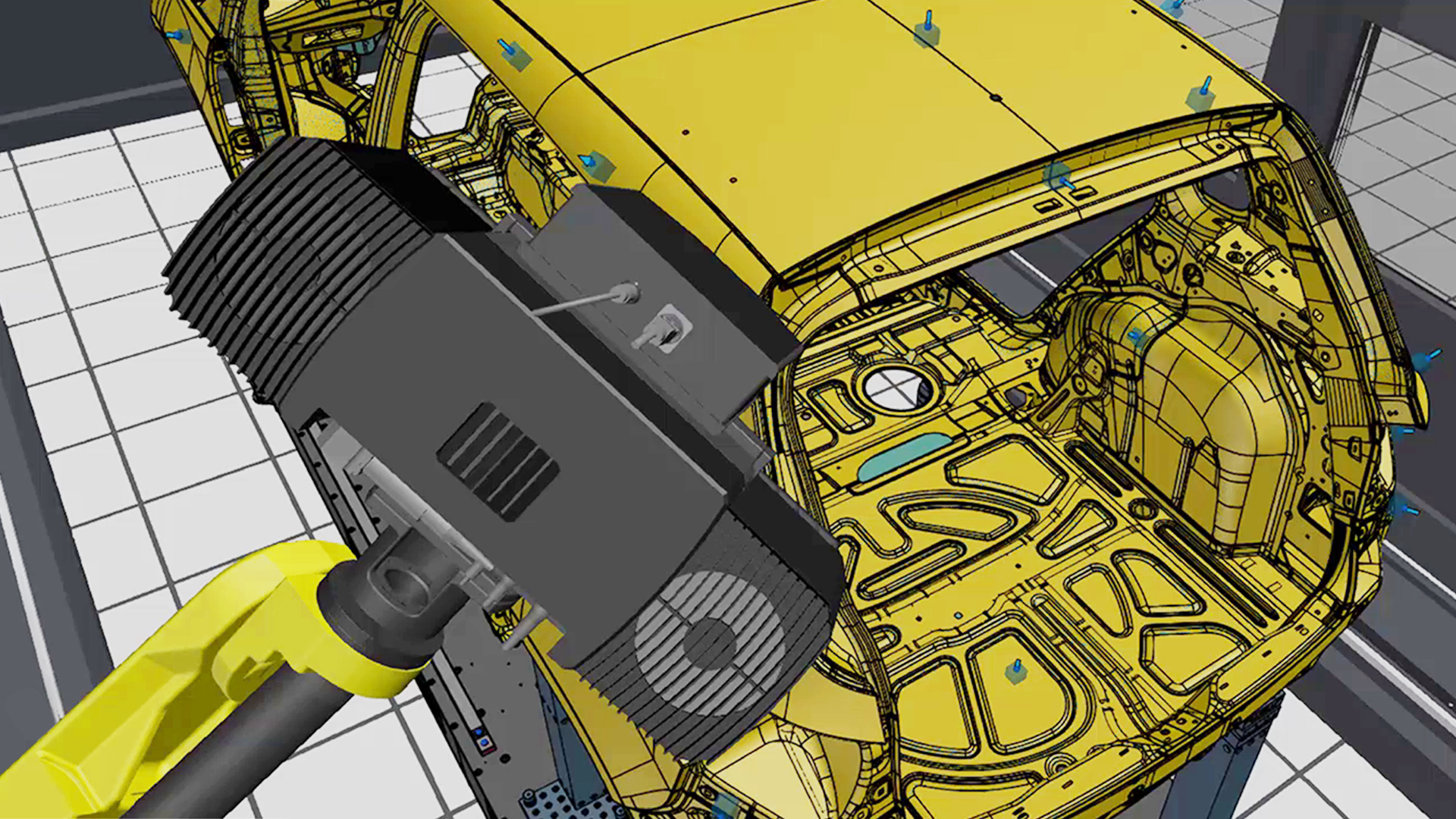

Cellule virtuelle de mesure dans le logiciel de métrologie 3D

La cellule virtuelle de mesure (VMR) est le logiciel central de commande et de planification de la mesure pour tous les éléments des cellules de mesure sans contact. Dans ses fonctions, la VMR représente l'environnement réel, c'est-à-dire les robots, les capteurs et les composants situés dans la cellule de mesure sous forme d'une simulation. La programmation comprend la cinématique, les trajectoires du robot, la monture et le plan de mesure. Grâce à la VMR, l'utilisateur peut travailler avec le système sans devoir disposer de compétences spécifiques en programmation robotique. Tous les mouvements du robot sont simulés et vérifiés à des fins de sécurité avant d'être transposés dans l'environnement réel.

Compatibilité des capteurs

Les têtes de mesure ATOS fournissent des coordonnées 3D plein champ complètes pour chaque mesure. En quelques secondes seulement, jusqu'à 12 millions de points de mesure indépendants sont capturés par scan. Les données de mesure qui en résultent se caractérisent par une reproduction extrêmement détaillée, ce qui permet de mesurer les composants dans leurs moindres détails.

Informations techniques

| |

ZEISS ScanBox 5110 RC |

ZEISS ScanBox 5120 RC |

| Dimensions |

2200 x 2850 x 3050 mm |

3600 x 3550 x 3050 mm |

| Alimentation électrique |

200 - 500 V (triphasé, 16 A) |

200 - 500 V (triphasé, 16 A) |

| Taille max. de composant |

Ø 1000 mm |

Ø 2000 mm |

| Poids max. composant |

2000 kg |

2000 kg |

| Entrée |

Porte coulissante avec interrupteur de sécurité |

Porte coulissante avec interrupteur de sécurité |

| Larguer d'ouverture porte coulissante |

1000 mm |

1350 mm |

| Concept de chargement |

Automatisé via la porte coulissante motorisée ou manuel par la porte de sécurité |

Automatisé via la porte coulissante motorisée ou manuel par la porte de sécurité |

| Compatibilité des capteurs |

ATOS 5 for Airfoil, ATOS 5* |

ATOS 5*, ATOS 5 for Airfoil |

* Vérification nécessaire de la configuration

Services

GOM assiste ses clients bien après l'achat et l'installation des systèmes de mesure 3D.