三维测试

三维测试

实时变形测量

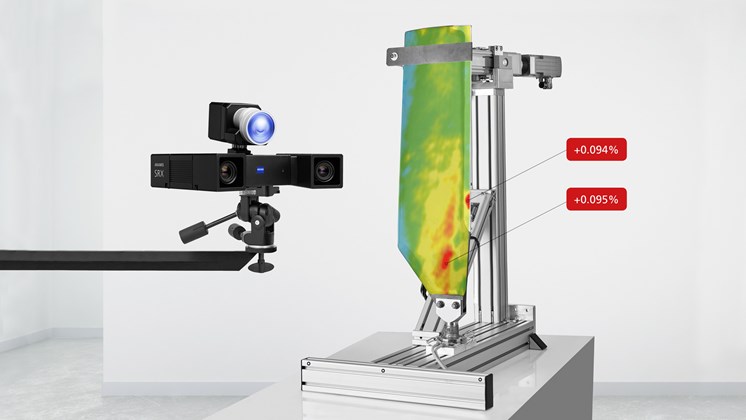

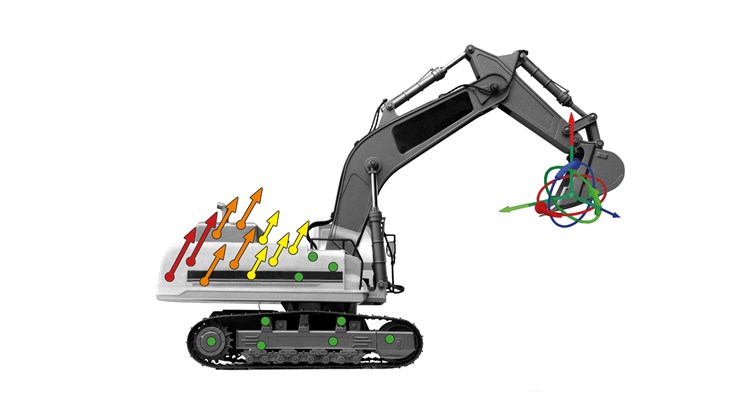

ARAMIS产品组合包括用于动态测量三维坐标、三维位移和三维表面应变的测量头。系统基于三角测量原理为全场基于点的测量提供精确的三维坐标。

光学三维运动和应变分析

适用于产品开发,材料研究和组件测试

分析结果提供有关材料特性和部件在载荷下的行为的信息,为测试产品耐用性,几何布局,可靠的数值模拟及其验证提供数据基础。

快速简单的测试流程

ARAMIS测量头可以测量静态和动态加载下的试样和零件,基于数字图像相关原理,采用非接触式测量方式,不受被测材料限制,无需对试样进行费时和昂贵的制备。

高精度测量小型和大型物体

ARAMIS系统为试样分析提供了稳定的解决方案,测量范围涵盖几毫米的试样到数十米的结构件。测量精度高,分辨率可以达到亚微米级别,不受试样几何形状和温度局限。

Metrology Story

Dresden University of Technology

Analysis of physical effect chains

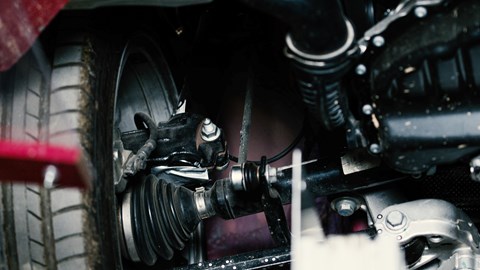

At the Vehicle Testing Centre (FVZ) of the TU Dresden ARAMIS SRX sensors are used to carry out dynamic analyses on complete vehicles in the test bench. Emphasis is given to evaluating the interaction of the parts chassis, axles and tires.

ARAMIS 测头概念

ARAMIS适用于测试应用

集成到测试环境

集成的GOM测试控制器不仅控制阶段采集,还可以管控照明条件。同时集成基于软件的编程接口,用于预设或用户自定义的测量序列。

多测头

结合多个ARAMIS测头可从不同角度对不同的测量区域进行测量,并在一个公共坐标系下对捕捉到的测量数据进行评估。

测量体积大

对于复杂或大型组件的动态测量,ARAMIS还可以评估例如重负载下的风力发电机的各个叶片的振动性能。

长时间在线测量

在线组件测试可用于例如耐久性测试,疲劳测试以及风洞测试和振动分析。测量结果可以被在线查看或由其他程序实时处理。

ARAMIS Kiosk界面—自动化检查

ARAMIS Kiosk界面是用于自动评估符合不同标准的拉伸试验的人机交互界面。通过最少的用户交互,快速、轻松、可重复地执行标准化测试程序,并将其用于无数个样本的测量系列。

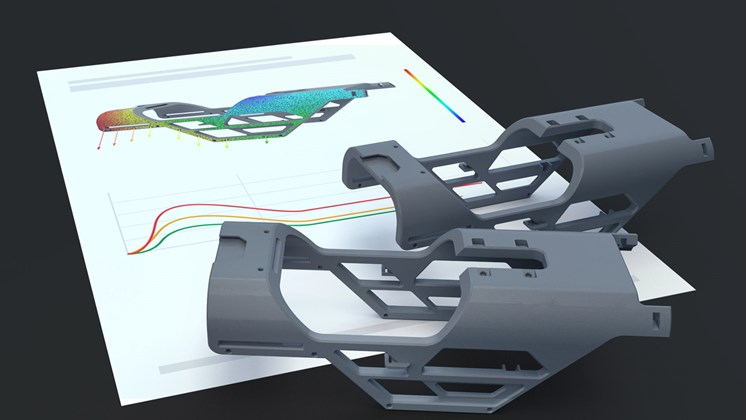

数值模拟验证

ARAMIS测头可提供有关零件材料特性的数据,该信数据可作为仿真计算的输入参数和优化和验证所需的参考数值。 GOM软件允许从包括ABAQUS,LS-DYNA和ANSYS在内的格式导入FE数据,并将它们与测量数据和空间位置对齐。

ARAMIS生成精确数据

- 三维位移

- 三维变形

- 速度和加速度

- 表面应变

- 数字图像相关(DIC)

- 用于仿真的材料属性

- 6个自由度评估(6DoF)

- 三维坐标

ARAMIS Professional 软件 – 数字图像相关

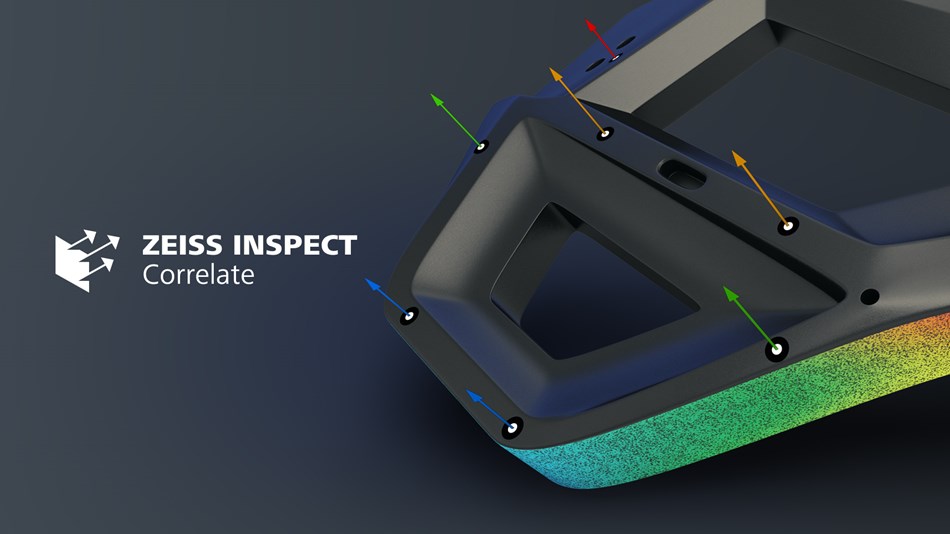

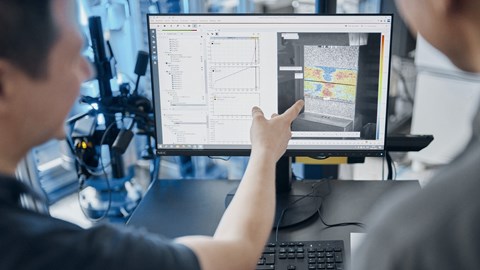

ARAMIS Professional软件提供从测量数据采集,分析,到出具报告的完整工作流程。 它将ARAMIS测头的图像和模拟数据同步采集功能以及GOM Correlate软件的评估功能相结合。

应用

Industries

Automotive

In e-mobility, lightweight construction or classic disciplines of vehicle development: With 3D measuring data from ARAMIS, OEMs and service providers can reliably meet the stringent requirements regarding safety, function and service life.

Aerospace

In the aerospace sector, ARAMIS has established itself as an indispensable measuring solution for characterizing all kinds of materials and for analyzing the reaction of prototypes, components and structures to mechanical loads.

Electronics

ARAMIS provides the competitive advantage that companies need in this fast-paced industry: more efficiency in product development combined with essential expert knowledge regarding materials and parts.

Medical Technology

Optical 3D metrology provides valuable insights for research on new materials and the development of orthopedic implants and sports products.

Power & Energy

The energy sector is facing a huge transformation in the course of the expansion of renewable energies. Energy-producing companies must always keep the safety of their plants in mind. In order to ensure safety, a large number of mechanical tests such as tensile, compressive and bending tests are carried out. In addition, vibration tests on components such as generators and turbines play an important role in ensuring that the components can withstand the high loads caused by vibrations during operation. ZEISS ARAMIS is the optical measurement solution for the determination of strains, deformations and displacements in 3D.

Fields of application

Materials characterization

Precise, full-field ARAMIS measuring results improve the accuracy of material characteristics. Existing evaluation procedures are optimized and become more reliable, such as the determination of flow curves and forming limit curves. Some material tests can only be performed due to the non-contact method of ARAMIS measurements and the high local resolution of the results. This is applied to tensile, shear, compression and 3-point bending tests as well as to high-speed and temperature tests.

Prototype testing

ARAMIS is used for strength and vibration analyses, fatigue limit and crash tests. The measuring results form the basis for determining product durability and load limits and for optimizing the geometrical layout. During load testing, the system measures the real part geometry along with the non-linear deformation behavior and allows for direct comparison with FEM data.

Validating numerical simulations

ARAMIS sensors provide information on material properties, the deformation behavior of parts and the boundary conditions of test setups. The measurement data are used as input parameters for simulation computations and for optimization and validation of FEA models. The software allows for importing FE data from ABAQUS, PAMSTAMP, LS-DYNA and ANSYS, AUTOFORM as well as for aligning them in 3D to the measuring data and in space.

光学成形应变分析解决方案

服务支持

GOM为购买和安装过三维测量系统的客户提供持续的服务和技术支持。