- Full-field 3D Data

- High-accuracy data from complete surface inspection

- Optimized Processes

- Increased overall throughput with automated systems

Aerostructures Inspection

Multiple Optical Solutions for Rapid Aerostructure Inspections

Aerospace manufacturing relies on thorough inspections of critical parts to ensure proper operation of the aircraft and the safety of the passengers. Small structural defects during the manufacturing process can spell trouble for manufacturers and even worse for passengers in flight. OEMs and suppliers see the benefit of non-contact measurements and NDT, such as faster inspection times, higher accuracy, and shorter production cycles. Implementing such technology helps make aviation safer for every touchpoint involved.

The Solution

GOM technology is used all over the product life cycle, especially with aircraft structures.

Applications

In research and development the ARAMIS Digital Image Correlation system helps measure material properties, limit loads and fatigue characteristics of structural components. In manufacturing, the ATOS 3D Scanners are used at different stages of the production to ensure the quality build of a Digital Twin for each aircraft. In MRO, GOM’s NDT solutions can detect defects to structural components that help reverse engineer parts for faster turnaround rates.

Unique technology

What makes GOM unique is what makes it industry-leading: its unparalleled speed in inspection, higher data capture per scan, high resolution cameras with precise accuracy, and its ability to create a Digital Twin of the aircraft using powerful analytics in the GOM software.

ATOS Solutions Provide

- Faster Scan Times

- High-speed and accurate results (in as little as 10 min)

- Maximized ROI

- Projected return on investment within two years

Manufacturing

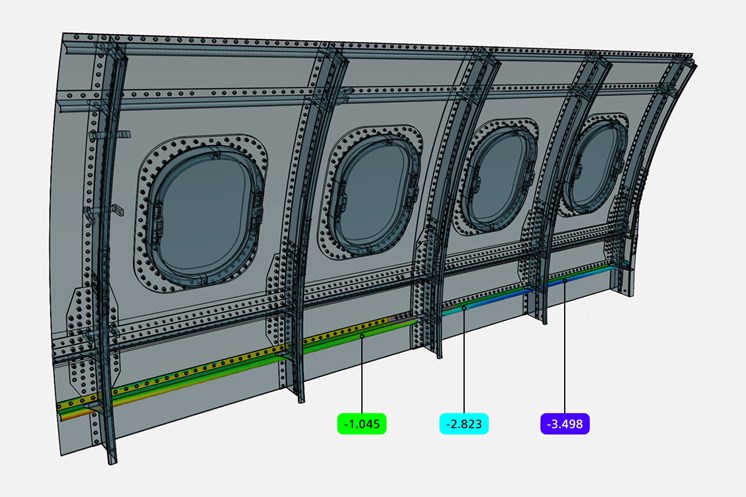

Whether it’s stringers, frames, or ribs, all aircraft structure components alike need to be manufactured at tight tolerances to ensure structural safety.

The problem

But high quality and high accuracy are costly, and suppliers must meet the ever-increasing demand while keeping costs at minimum. With thousands of structural components in each aircraft manufacturers need flexible measurement solutions that accommodate large components quickly and with incredible accuracy (within microns) to shorten and optimize their manufacturing cycle times. Optical 3D measurement systems, like GOM’s, are the industry’s best solution to maximizing efficiency and productivity within aircraft structure inspection.

Our solution

GOM’s ATOS systems have been developed to help speed up manufacturing cycles with the use of advanced hardware and intelligent software. This combination delivers high-accuracy measurements through a range of industrial solutions proven to accelerate productivity and profitability. With GOM Blade Inspect Pro the creation of a digital copy, or Digital Twin, of the aircraft is achieved and accessed over time to ensure quality build of every component during the manufacturing process, and is used to streamline maintenance operations or service bulletins.

ATOS ScanBox 7 Series + ATOS 5

The ATOS ScanBox Series 7 equipped with the powerful ATOS 5 is the answer to measuring large aerostructures efficiently and accurately. This automated piece of metrology performs complete analysis measurements on large volume parts (up to 6 m) while the ATOS 5 visualizes hidden errors by capturing high-precision data in rapid time. Complete with 8-axis kinematics, the ATOS ScanBox 7 Series allows high flexibility in positioning the ATOS 5 thanks to its 8 degrees of freedom. The ATOS 5 has a powerful built-in light source that captures high-precision data with 0.2 seconds per scan and 100 frames per second. Thanks to its industry-leading camera sensors and projection technology, the ATOS 5 requires fewer individual scans and thus accelerates the entire measuring procedure.

GOM Inspect Pro

This dynamic hardware is supported by GOM Inspect Pro and the Virtual Measuring Room (VMR). It’s the central control station and the functional representation of a real measurement environment in a virtual simulation. While traditional CMMs take hours to program, VMR takes away the hassle of programming robots and only takes minutes to set up within the software. The Professional Suite platform enables thorough inspection of aerostructures throughout their entire lifecycle, while simultaneously generating a digital twin to verify quality during the manufacturing cycles.

Maintenance, Repair & Overhaul

If the average global citizen travels once every 21 months, it’s no surprise that suppliers and OEMs are feeling the pressure of the overwhelming demand for MRO services. Identifying hidden errors, deformations, and defects is crucial to making sure aircrafts stay in the air longer than they are in MRO hangars. Time and money is a priority, so achieving rapid measuring times and high-accuracy for exacting measurements is essential when it comes to inspecting aerostructures. It becomes an even bigger challenge when spare parts or a CAD file aren’t available to OEMs and are needed for replacements.

Our Solutions

ATOS 5

GOM’s non-contact solutions simplify preventive maintenance and help reverse engineer parts for faster turnaround rates. These solutions take form in the innovative technology of the ATOS 5 and ATOS Compact Scan for MRO applications. Both these sensors encompass the best of GOM technology; the high-powered structured blue light, live tracking, and patented Triple Scan Principle provide precise scans with detailed resolution at high speed.

ATOS Compact Scan

ATOS 5 has unrivaled speed, requiring fewer scans and capturing more point cloud data than competing scanners while the ATOS Compact Scan is the mobile 3D scanning solution and can be placed anywhere along the aircraft for optimal inspection. With the amount of data these two capture, MRO teams can quickly re-create the structures they need with minimal aircraft downtime.

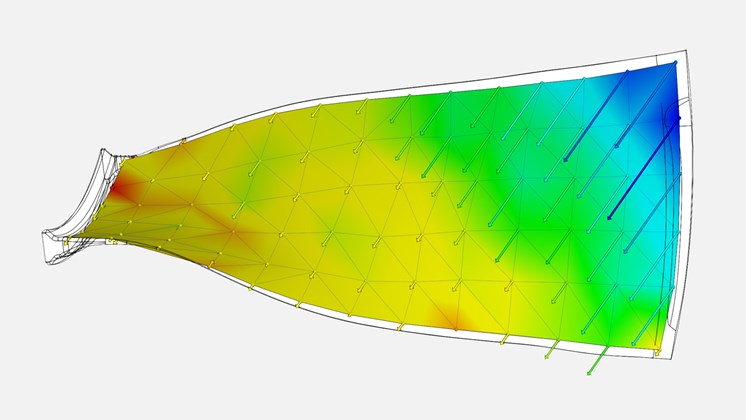

Research & Development

Aircrafts need to have a structure that can handle high fatigue cycles caused for example by flutter or low cycle fatigues such as hard landings and heavy loads. Correspondingly in R&D, OEMs and suppliers test new materials for aircraft structure intensively to guarantee their performance, safety and durability. While they test material properties, they also perform simulation verification. Strain gauges can take days to set up and require more manpower than 3D technology. Therefore optical 3D systems become the perfect tool to perform both functions; determining static and dynamic deformations in testing and comparing simulations with reality in the form of easy-to-follow charts, videos and images.

ARAMIS hardware & software

ARAMIS is GOM’s upgrade from strain gauges and displacement sensors; a stereoscopic 3D optical sensor capable of measuring 3D strains and displacements. GOM’s software suite can rapidly analyse test data for easy validation of structural simulations, providing a quicker process with less testing iterations.The results enable users to review and improve simulation parameters, as well as optimize current and future design processes. Therefore they can reduce the number of costly test runs and consequently speed up product development. At the same time, the results show insights into safety risks, part durability, as well as creep and aging processes. This increases not only the safety, but also the lifetime of products.

ARAMIS Solutions Provide

- Flexible Systems

- Physical capabilities to capture complex geometries

- Faster, Relevant Data

- Rapid data capture outpaces standard contact sensors

- Real-Time Inspection

- Instant measurement of deformations and strain

- Optimized Setup

- Accelerated test setup with comprehensive software