- Intuitive

- Sophisticated software user interface for error-free operation

- Robust

- Temperature stable, maintenance free, vibration resistant

- Data quality

- Self-monitoring system with continuous image quality feedback

- Fast

- Significantly reduced measuring time, easy measurement preparation

TRITOP

3D coordinates for efficient inspections

TRITOP captures precise three-dimensional coordinates of individual measuring points on objects. High-resolution images are acquired in a short time using a digital measuring camera. The integrated software then automatically creates 3D point clouds for further metrological analysis, including inspection and display of displacements and deformations. Visualization of the results speeds up evaluation. As a portable system, TRITOP is suitable for tasks in 3D coordinate measuring technology and 3D testing.

All object sizes

Measuring system comes to the measuring object

Especially when inspecting large objects, such as ships or wind turbines, TRITOP brings the “measuring system comes to the measuring object” principle into best practice. The flexible system is at its best with parts of any size and almost any material.

Indoor to offshore

Independent of ambient conditions

TRITOP is specially designed for harsh measurement environments and captures precise 3D coordinates in a significantly reduced measuring time, even in demanding environments: directly in production, in a climate chamber or offshore. The system delivers accurate measurement results even under difficult lighting conditions. With minimal hardware requirements, this handheld, wireless solution offers complete mobility regardless of location.

Non-contact measurement

Ease of use

TRITOP allows for non-contact acquisition of 3D coordinates. The system really comes into its own in confined spaces and areas that are difficult to access. Fragile objects and sensitive surfaces can also be measured. TRITOP therefore replaces conventional measuring methods, such as tape measures and string lines, as well as complex conventional displacement measuring systems or LVDTs.

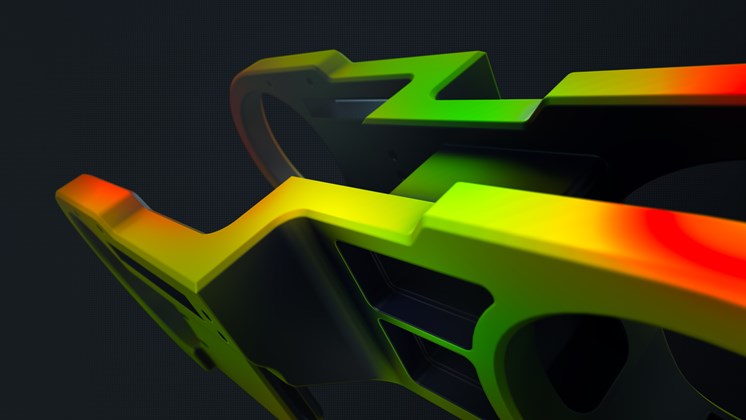

Effective tool for analysis

Powerful software ZEISS INSPECT

TRITOP comes with the high-performance software ZEISS INSPECT. It guides the user through the entire measurement and evaluation process in an uncomplicated and reliable manner. The analysis tool enables the visualization of measurement results and a wide range of analyses. It also includes comprehensive reporting functions.

Unbeatable team

TRITOP as extension for ATOS

To accurately inspect very large and often complex parts, TRITOP starts by creating reference point clouds. The ATOS optical 3D scanner then uses these reference points to automatically transform the individual measurements and to achieve the overall accuracy of the photogrammetric measurement over the entire measurement area.

Measuring by taking photos

In photogrammetric measurement with TRITOP, the object coordinates are recorded using a digital measuring camera. TRITOP first photographs the object to be measured from different angles, then the software automatically calculates the 3D coordinates using the bundle adjustment of all the 2D images taken.

Quickly overcome challenges in any location

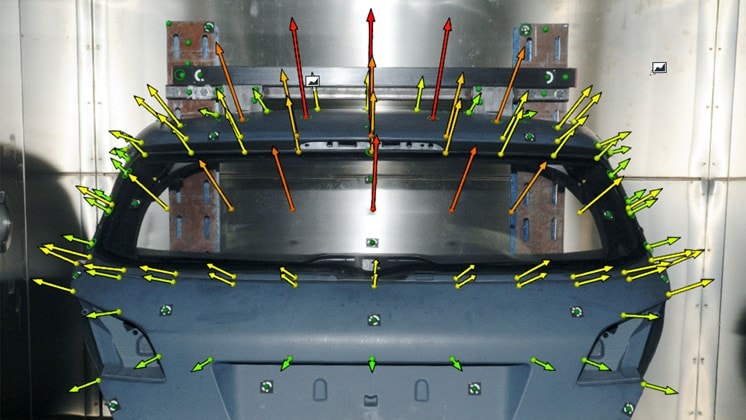

Static deformation analysis

TRITOP determines displacements and deformations in climate chamber tests, environmental simulations, load and ageing tests and analyses gap and flush changes as well as stiffness.

Wind turbines

Wind turbines are often not assembled until they reach their destination. TRITOP provides accurate 3D coordinates of mounting bolts and mounting surfaces in the demanding offshore measurement environment.

Ship building

TRITOP reduces the time ships spend in dry dock from months to days. The measurement data helps to inspect ship hulls and reconstruct spare parts.

Train wagon construction

With a wide range of options for analysing flatness, parallelism and squareness, TRITOP speeds up the measurement and inspection process.