GOM - Accueil

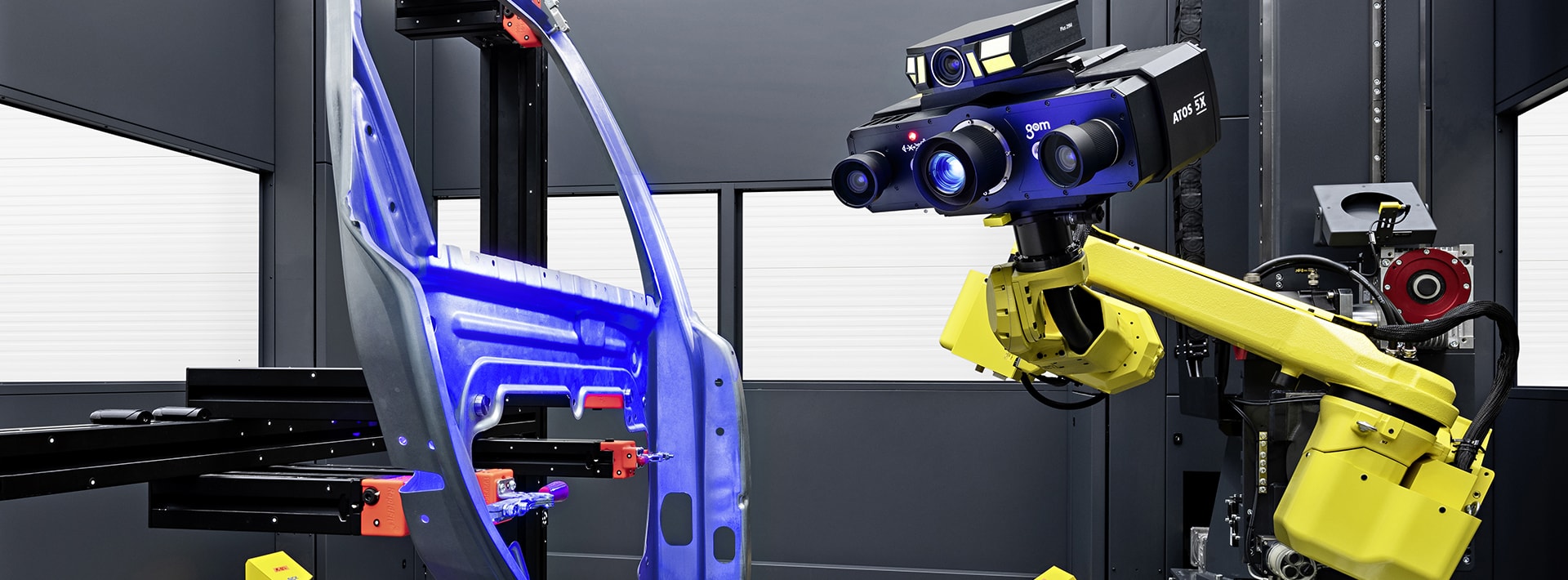

ScanBox établit de nouvelles références en matière de métrologie 3D industrielle

ScanBox est une machine de mesure optique qui permet de réaliser des mesures rapides et précises afin de réaliser le contrôle qualité des composants dès les processus de production et de fabrication. Disponibles en onze modèles, les systèmes de mesure fournissent des résultats précis et traçables, garantissent des rendements élevés et sont faciles à utiliser grâce à une interface utilisateur intuitive et à la chambre virtuelle de mesure (VMR) servant de poste de commande central et de logiciel de planification des mesures.

Contrôle non destructif avec données CT

Avec ZEISS INSPECT X-Ray, vous pouvez visualiser les volumes et les sections en 2D et 3D pour établir une évaluation et un rapport complets.

Démos numériques en ligne

Les experts GOM présentent en direct la métrologie 3D dans des essais pratiques personnalisés. Ces essais sont spécialement pensés pour votre application, avec votre propre composant ou un composant de démonstration. Prenez rendez-vous dès maintenant !

L'innovation au cœur de notre stratégie

Façonner la qualité

Qu'il s'agisse de la technologie Triple Scan, de l'ATOS ScanBox ou du logiciel GOM Inspect, GOM est synonyme d'innovations technologiques et de quête permanente d'excellence. Cette démarche englobe les initiatives de l'entreprise en matière de durabilité et de convivialité pour les familles.

Responsable de notre environnement

La conscience écologique de GOM ne se limite pas au concept écoénergétique du bâtiment de l'entreprise. Nous utilisons également des articles réutilisables dans notre restaurant pour lutter contre la consommation croissante d'emballages jetables.

Créer un environnement de travail attractif

Dans notre région, GOM est considérée comme un employeur de choix. GOM a également été reconnue comme un employeur attentif aux besoins des familles. Les horaires flexibles et les subventions pour les services de garde d'enfants permettent de concilier vie professionnelle et vie familiale.

Pour les normes de métrologie 3D de demain

GOM a établi des normes dans de nombreux secteurs. Pour continuer sur cette voie, nous travaillons en permanence sur de nouvelles solutions innovantes.

Le réseau GOM

Avec plus de 60 sites et plus de 1200 spécialistes en métrologie, GOM garantit des conseils, une assistance et des services professionnels dans toutes les langues.