GOM Webinars

GOM Webinars

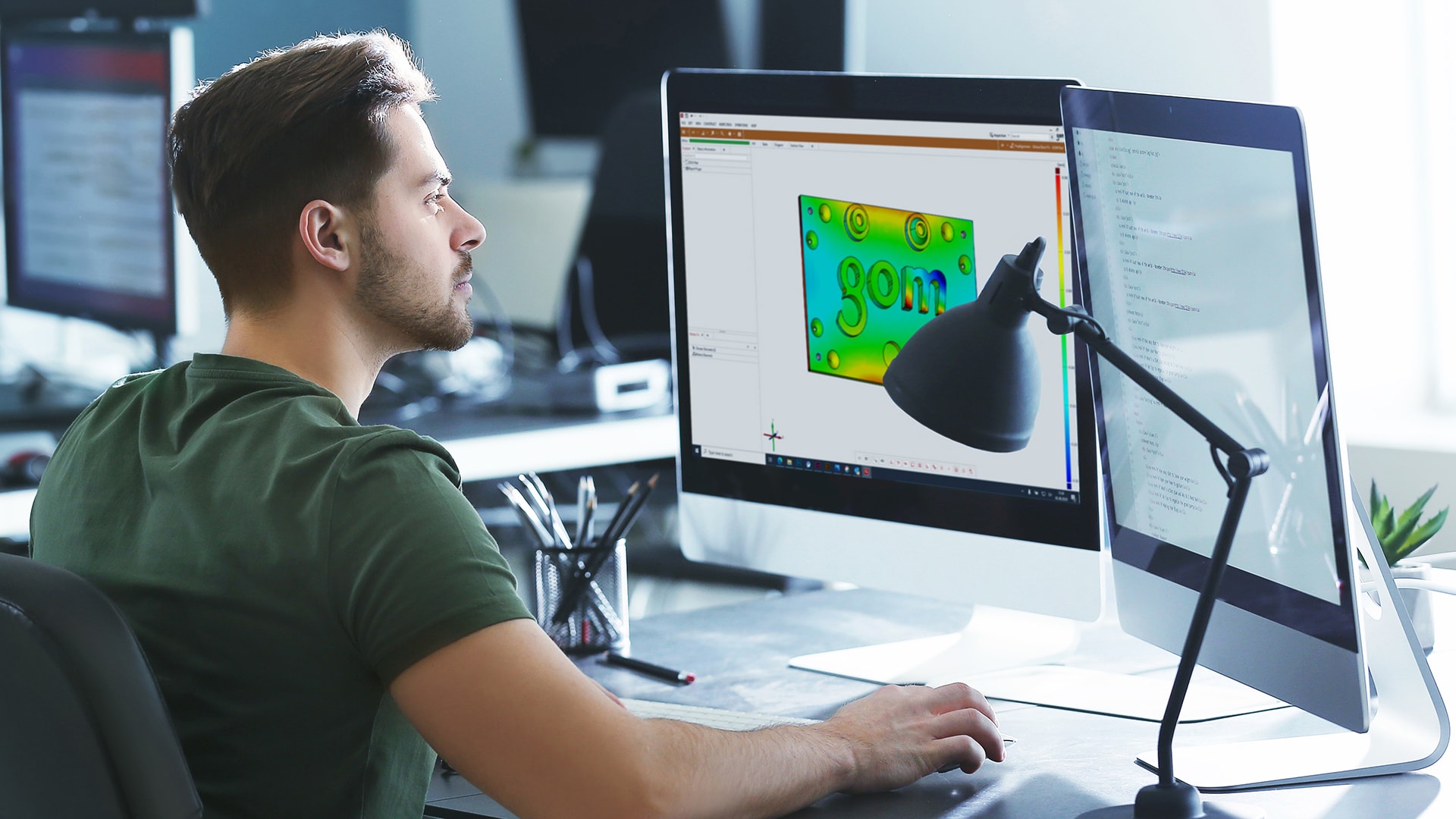

GOM webinars allow users to benefit from the specialist expertise of the webinar hosts. After free registration, participants learn essential operations and are provided with specific background information on software features and concepts as well as on the application fields of GOM systems.