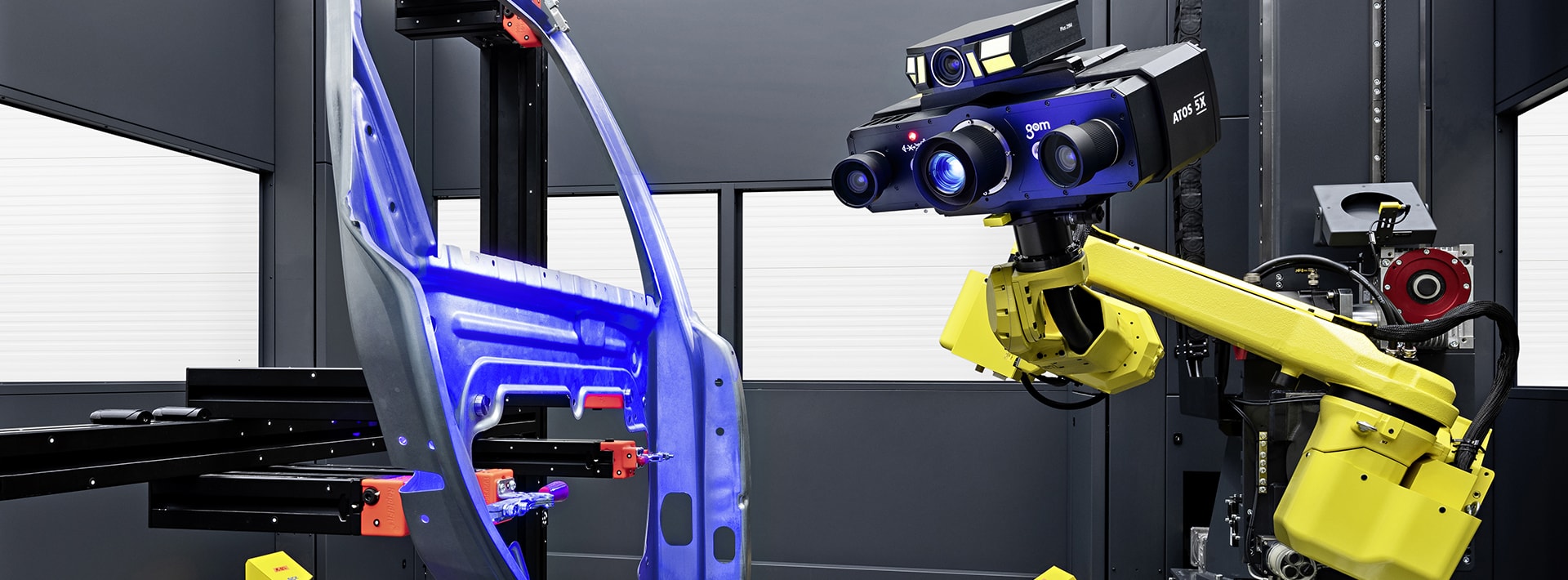

ScanBox Sets New Standards in Industrial 3D Metrology

ScanBox is an optical measuring machine that supports customers with fast and precise measurements for quality control in the production and manufacturing process. Available in eleven models, the measurement systems deliver accurate and traceable results, guarantee high throughputs and are easy to operate thanks to an intuitive user interface and the Virtual Measuring Room (VMR) as central control and measurement planning software.

Non-destructive inspection with CT data

With ZEISS INSPECT X-Ray, you can visualize volumes and sections in 2D and 3D for a complete evaluation and reporting.

Live Digital Demos

GOM experts present live 3D metrology in individual practical tests. Especially for your application, with your own component or a demo part. Arrange your appointment now!

Our focus on innovation

Shaping quality

Triple Scan Technology, ATOS ScanBox or the GOM Inspect software - GOM stands for technological innovations with a continuous strive for excellence. This includes the company initiatives in sustainability and family friendliness.

Responsible with our environment

GOM shows environmental awareness not only in the energy concept of the company building. We also use reusable items in our restaurant to counteract the increasing consumption of disposable packaging.

Create an appealing working environment

In our region, GOM is considered a TOP employer. Now GOM has also been recognized as a family-friendly employer. Flexitime and subsidies for childcare help to balance work and family life.

For tomorrow's 3D metrology standards

GOM has established standards in many industries. To keep it that way, we are working on new cutting-edge solutions.

GOM Network

At over 60 locations with more than 1,200 metrology specialists, GOM guarantees professional advice, support and service in the local languages.