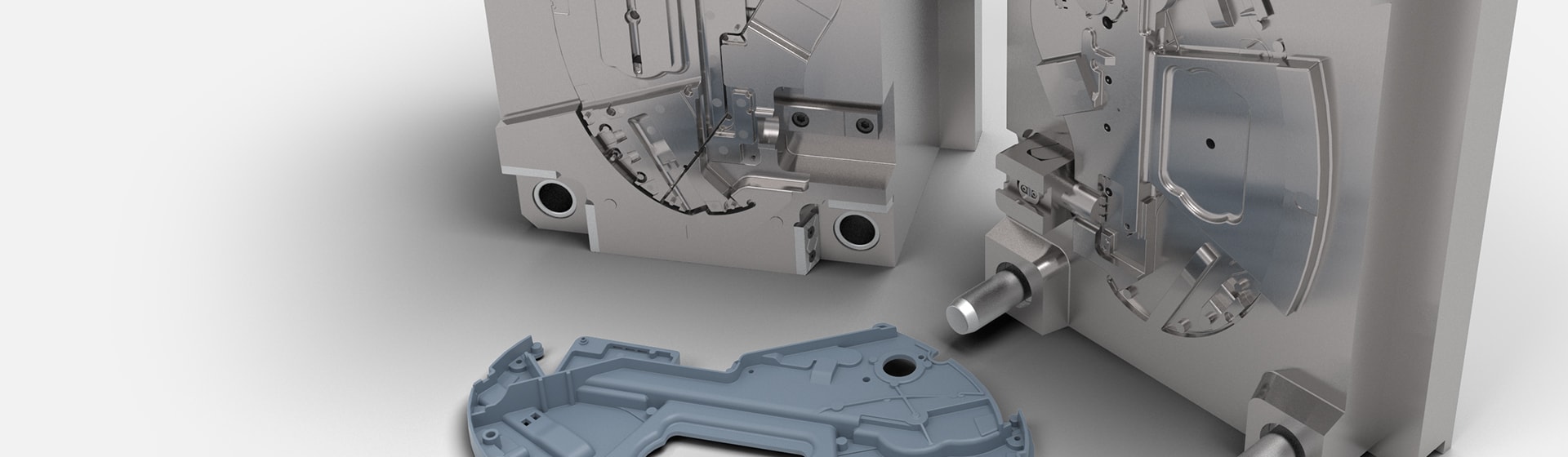

Tools and Electrodes (CAD/CAM)

Fast Inspection and Modification of Tools and Electrodes

3D digitizing saves time and costs during tool and electrode production and maintenance. Process control at an early stage reduces correction loops, especially for multiple cavities. The comparison of nominal and actual part data serves to control the individual steps during CNC machining of the tool. In try-out, GOM’s ATOS system measures complex geometries, offering 3D data for a specific tool correction and a lower material input.

Applications

- Optimization of multiple cavities

- Check erodible areas and create electrodes

- Targeted tool correction

- Wear control

- Dynamic 3D motion analysis

Benefits

Warpage and deformation measurements of plastic parts during mold validation lead to a targeted tool optimization. The virtual assembly analysis serves for the inspection of contact surfaces and tool offset. Dynamic 3D motion analyses of the tool carried out with the ARAMIS system help to recognize relative movements between the mold halves with various injection parameters (mold breathing).