ZEISS Quality Training Center

Never Stop Learning!

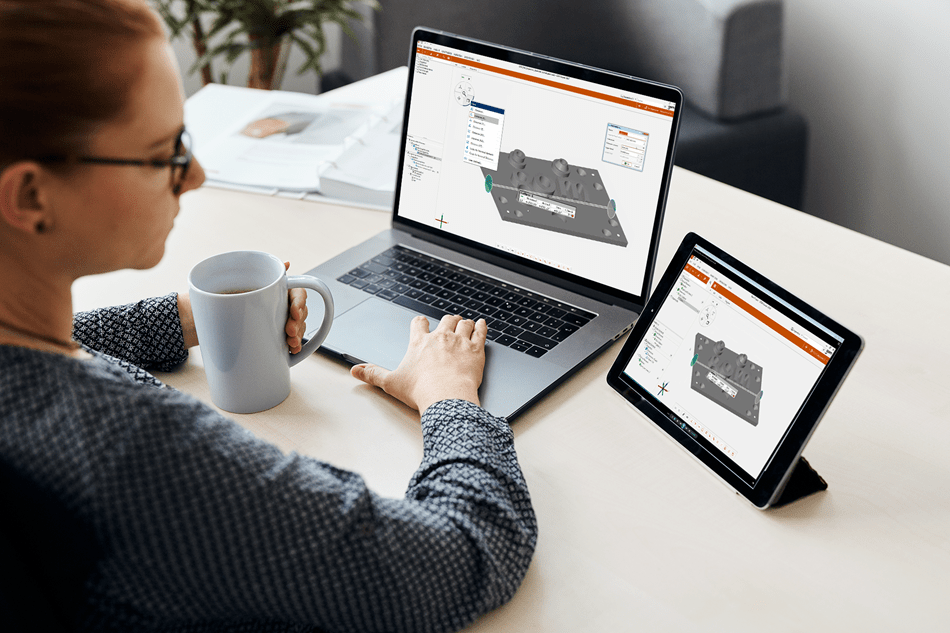

Get the best out of your product by attending our training courses. In local in-person or classroom courses and live online training sessions or time-flexible eLearning courses, you can experience how easy it is to work with your system and software.

Get detailed information about all training courses by creating your personalized account in the ZEISS Quality Training Center. You can then register for courses, view and manage your course progress and certificates at any time.