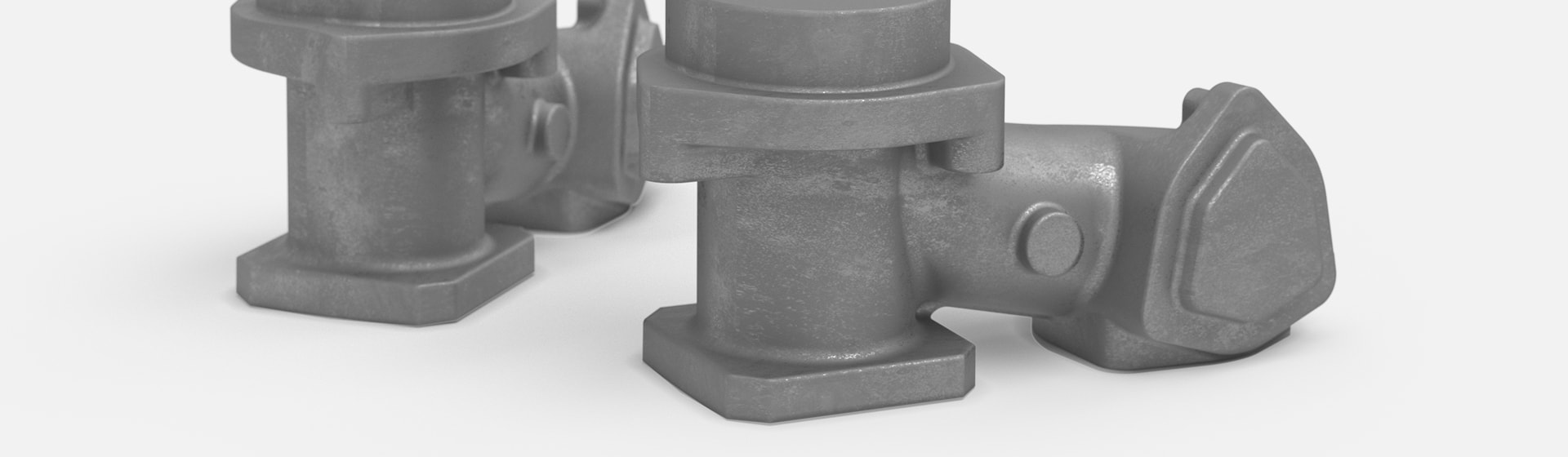

First Article Inspection / Series Inspection

Automated First Article Inspection and Production Control

The first article inspection can be carried out based on the CAD model or PMI data set and CMM inspection with features such as GD&T. The full-field 3D inspection performed with GOM’s ATOS systems leaves no area of the component unchecked. In quality control during series production, automated, production-related and mobile measuring cells, such as ATOS ScanBox, reduce scrap and rework time. Parts do not have to be transported to remote measuring rooms.

Applications

- Control of warpage, shrinkage, wall thickness, sink marks

- Automated quality control and inspection reports

- Geometric Dimensioning and Tolerancing (GD&T)

- Statistical trend analysis, Cp/Cpk and Pp/Ppk values

Benefits

Get easily understandable results instead of long tabular inspection reports. This ensures a quick determination of corrective values. Turn-key measuring cells are flexible regarding the place of installation. They can be used directly in production and deliver fast measuring results. Automated measuring cells with integrated operational safety equipment are ready for use within one or two days and are operated by shop floor workers.