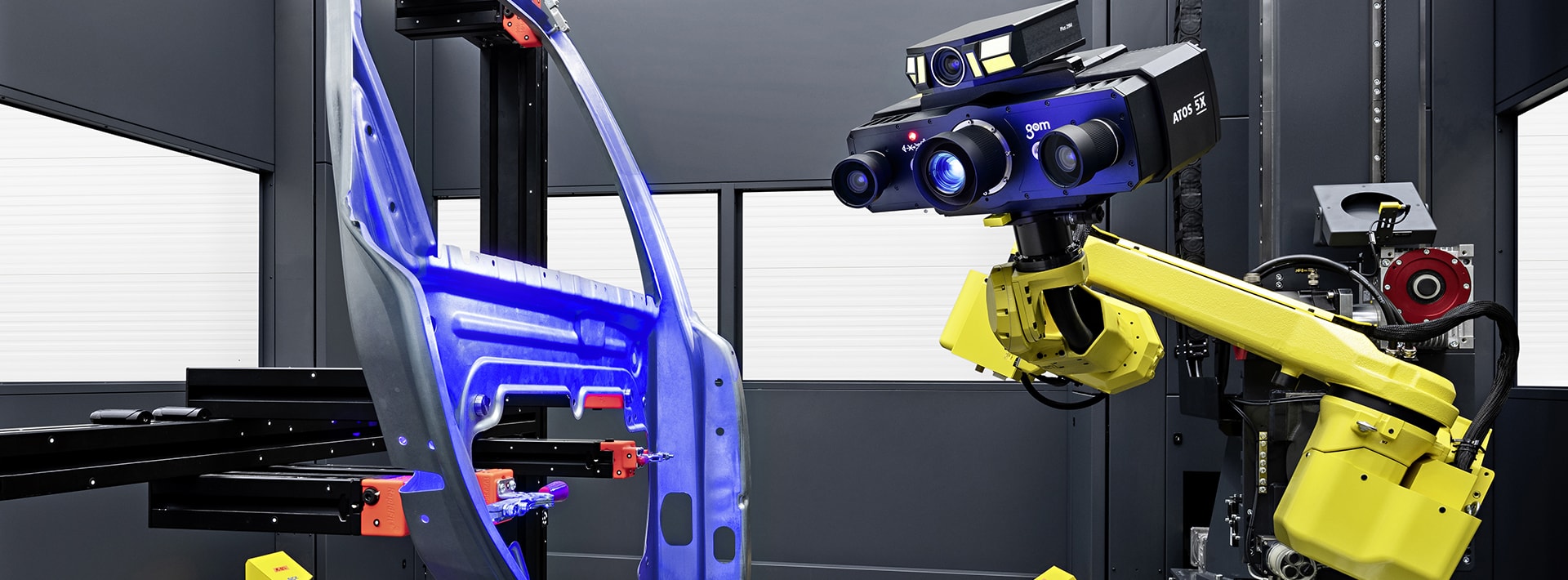

ScanBox definisce nuovi standard nella metrologia 3D industriale

ScanBox è una macchina di misura ottica che supporta i clienti con misurazioni veloci e precise per il controllo qualità nel processo di produzione e fabbricazione. Disponibili in undici modelli, i sistemi di misurazione forniscono risultati accurati e tracciabili, garantiscono un’elevata produttività e sono semplici da utilizzare grazie a un’interfaccia utente intuitiva e alla cella di misura virtuale (VMR) come software di controllo centrale e di pianificazione della misurazione.

Ispezione non distruttiva con dati TC

Con ZEISS INSPECT X-Ray è possibile visualizzare volumi e sezioni in 2D e 3D per una valutazione e una reportistica completa.

Demo digitali in tempo reale

Gli esperti GOM presentano la metrologia 3D in tempo reale con test pratici personalizzati. Specifici per le vostre applicazioni, con i vostri componenti o componenti demo. Fissate subito un appuntamento!

Il nostro focus è l’innovazione

Diamo forma alla qualità

Il principio della tripla scansione, ScanBox o software GOM Inspect: quando si parla di GOM, si parla di innovazioni tecnologiche continuamente proiettate verso l’eccellenza. Cui si affiancano iniziative aziendali in materia di sostenibilità e politiche a favore delle famiglie.

Responsabilità verso l’ambiente

GOM mostra la propria consapevolezza nei confronti dell’ambiente non solo nella concezione energetica degli edifici aziendali, ma anche nell’impiego di oggetti riutilizzabili nella mensa aziendale volto a contrastare il consumo sempre maggiore di prodotti usa e getta.

Creiamo un ambiente di lavoro stimolante

Nella nostra area, GOM è considerata un datore di lavoro d’eccellenza. L’azienda è ha inoltre recentemente ricevuto un riconoscimento per la propria politica a favore delle famiglie. L’orario flessibile e i sussidi per l’infanzia consentono di conciliare lavoro e vita familiare.

Gli standard della metrologia 3D del futuro

GOM ha definito standard in molti settori. Per mantenere la posizione acquisita, stiamo lavorando a nuove, avanguardistiche soluzioni.

GOM: la rete

Con oltre 60 uffici e una rete di oltre 1.200 esperti di metrologia, GOM assicura un servizio professionale di consulenza, supporto e assistenza in lingua locale.