Concentricity

Concentricity

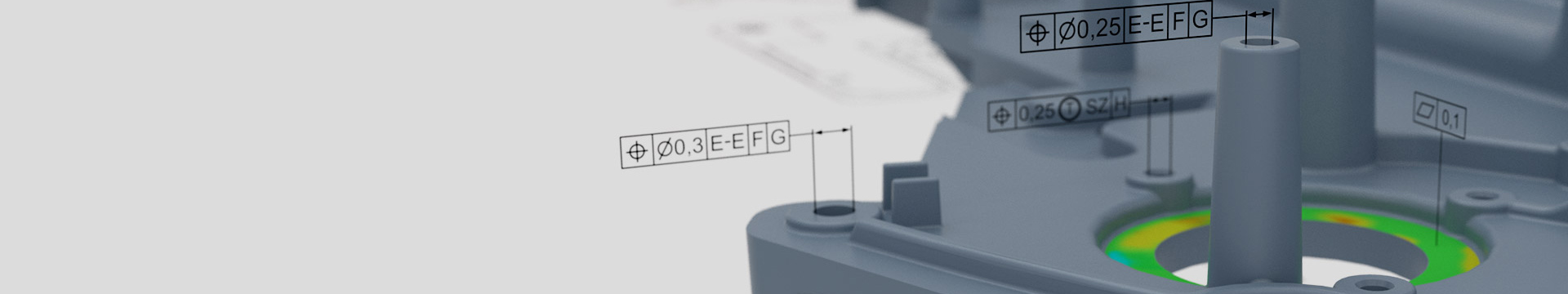

Concentricity is part of coaxiality. While the check for coaxiality includes the axes, the check for concentricity only includes the center point. These checks are usually performed several times on a part.

What is concentricity?

Concentricity is referred to as the location check of one or more independent circles. At first, the datum element is determined. This datum element can be either an axis or a center point. Then, a planar or circular tolerance zone is created around this datum element. The location of the center point is allowed to deviate within this tolerance zone. The dimension is considered out of tolerance if the center point is located outside the tolerance zone.

Concentricity in terms of metrology belongs location tolerances. Other location tolerances are, for example, position and symmetry tolerances. Imagine a washer with an outer diameter of 15 mm. In the center of the washer is a bore hole with a diameter of 10 mm. This bore hole serves as a datum element. With a concentricity tolerance of 0.4, the center point of the inner circle is then used as the datum. A circle with a diameter of 0.4 mm is created around the datum. This is the tolerance zone in which the center point of the outer diameter is allowed to be located. To achieve concentricity, the center point of the outer circle can only have a maximum radial offset of 0.2 mm to the center point of the inner circle. Otherwise, the center point would be out of tolerance.

The permissible deviations from the nominal dimensions (tolerances) occur during the manufacturing process. They often result from systematic or random influences on production, such as temperatures, vibrations or dirt. Knowing if the concentricity deviations are within the limit values is crucial for the later functioning of the part.

Applications of concentricity

The measurement of concentricity plays an important role in the production of precision ball bearings for the automotive and other industries. Rolling bearings are needed in automotive engineering. They reduce the energy consumption due to low friction. To ensure the best possible efficiency of the ball bearings, the metrological systems in use have to work with the highest precision. Classic inspections for ball bearings include:

- Diameter of the bearing groove and bore hole

- Concentricity of bore holes to the outer diameter

- Concentricity of bearing grooves to the outer diameter and bore hole

- Concentricity of seal grooves to the outer diameter

- Roundness of the bearing groove

Ball bearings are used in various products. They enable a smooth and fast rotation of parts that are required in drive technology, mechanical engineering and machine tool manufacturing.

Checking Concentricity

Optical 3D measurement technology enables non-contact measurements of concentricity by means of 3D scans. This enables high-speed measurements with the highest degree of detail.