- Quick identification

- of invisible material defects

Quick identification of material defects related to forming in tool try-out

Quick identification of material defects related to forming in tool try-out

The challenge

Apart from a check for correct shape and dimensional consistency of a part, it must be ensured during tool try-out that no material defects occur in the part during forming. During the forming process, excessive strain on some parts of the material or reduction of material thickness can occur. In such a case, the produced part is critically weakened and threatens to tear. These material defects are not visible to the naked eye.

The tool has to be revised in try-out so that the strain and material thickness of the part are still within the tolerance limits. This is achieved by adjusting the machine parameters or optimizing the tool geometry, for example.

The solution

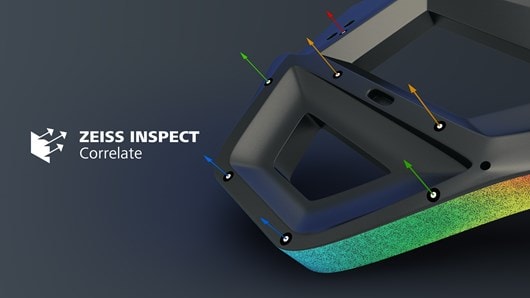

To find out whether a part has material defects, the material behavior during forming needs to be examined. The ARGUS system helps here. With the help of a corresponding measuring camera, changes in the shape of the entire surface can be scanned in 3D. This happens by taking only few measurement images of the part. From this 3D data, strain values of the entire surface of the part are calculated.

A forming limit diagram (FLD) is produced if the results are set into relation to the forming limit curve (FLC). The FLD reveals those areas in a part where machine parameters such as lubrication, contact pressure and workpiece positioning need to be adjusted. It also reveals if and where the tool geometry needs to be reworked.

The benefits

- Sufficient material thickness

- after process optimization

- Clear time savings

- compared to traditional forming analyses