Turbine Blade Inspection

Next Generation Optical Metrology Solutions for Turbine Blades

Turbine blades are the workhorse of the modern aero engine, primarily converting expanding hot gases into torque, power and thrust. Even a single civil HP blade generates ten times more power than a small family car. These blades must withstand the highest temperatures while producing maximum power, essentially pushing the boundaries of physics repeatedly (it compares to trying to stop an ice cube from melting in a 200ºC oven). Therefore, turbine blades need to exceed precision, design and inspection standards to maximize performance, efficiency and service life of the engine.

Our Solution

ATOS sensors are the powerful innovative solutions that the turbine blade industry trusts to increase throughput, reduce time-to-market and do it right first time on accelerated new engine programs. Given their ability to achieve high-speed, accurate measurements and inspections, the software/hardware combination of the ATOS technology ensures the quality of the turbine blades in every aspect, including:

- Measurement of castings, accuracy and airfoil features

- Wax/ceramic core measurement with GOM CT

- Use in adaptive machining for airfoil profiling – optimizing shape and edge geometries to meet demanding efficiency targets

- Repair activities

- Coating of airfoil and tip shroud features

- Measurement for first article inspection

Design and Composition

Turbine blades are continuously being designed for greater performance, longer lifespan, and fuel efficiency. Their designs have become increasingly intricate and harder to measure as they incorporate new geometries and different composites and castings. Due to the effect blade design and material have on engine performance and strength, high-precision accuracy is critical as inaccuracies can result in energy conversion loss and ultimately blade failure. Areas such as airfoil cross sections, alignment, blade profiles, trailing edge radii and root forms need to be measured non-destructively, which is a challenge for traditional measuring methods.

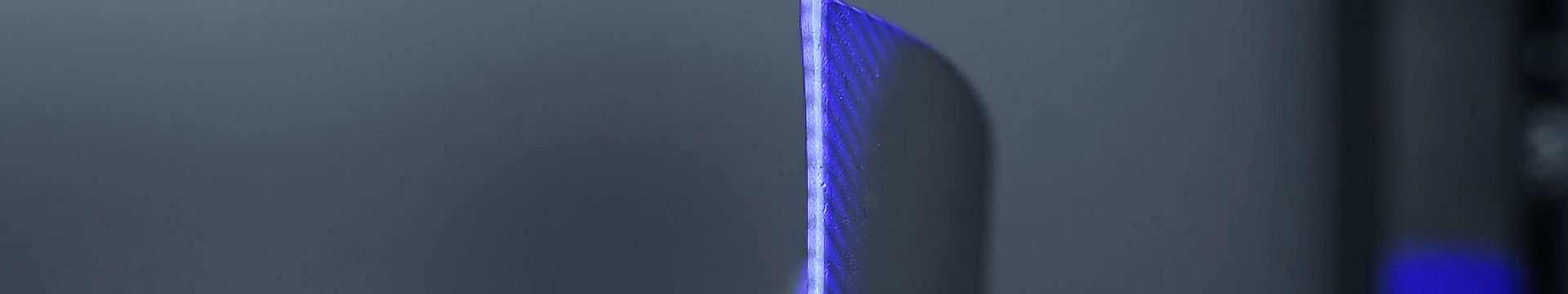

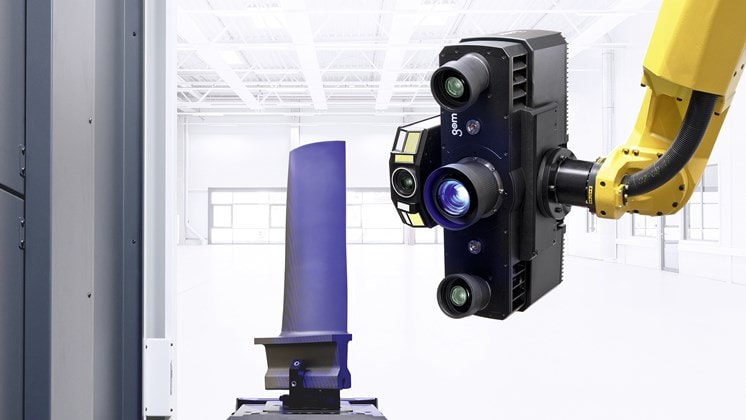

ATOS 5 for Airfoil

ATOS 5 for Airfoil is our own cutting-edge technology which we use to measure these advanced products. Developed exclusively for the industry, it measures complex airfoil geometries, particularly trailing edge geometries produced as part of the investment casting process which can be particularly small in the modern gas turbine.

GOM Inspect

Coupled with GOM Inspect software, our systems provide digital assembly capabilities to help analyze the performance of casting dies in relation to shrinkages and finished cast products in manufacture or the throat area in blade assemblies. Within minutes, the ATOS technology provides you with surface comparisons, form and position checks and precise blade measurements. This software and hardware duo delivers the ideal solution for higher accuracy and higher throughput for turbine inspection.

Manufacturing

Today’s market demands higher speeds, higher throughput at reduced timescales and smaller tolerances; this adds an immense amount of pressure to OEMs within their production programs. They have started turning to 3D optical metrology solutions as they improve productivity while decreasing inspection times, allowing them to keep up with the continuous stream of demand for turbine blades.

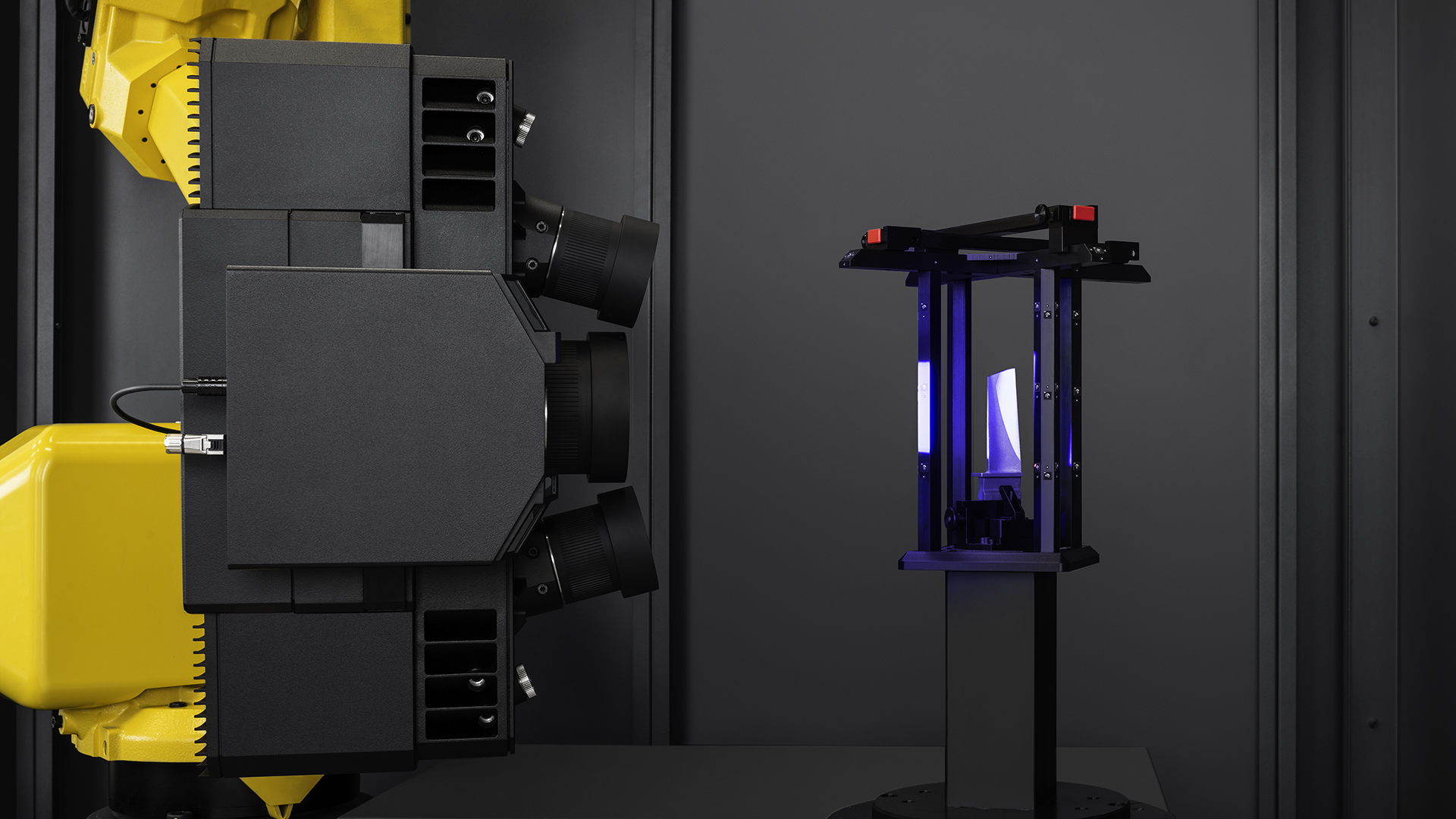

ATOS technology is the perfect solution for the high-volume aero manufacturer. Our sensors are the trusted product by OEMs and supply chain companies to optimize geometries, decrease inspection time and increase precision within their manufacturing processes. ATOS systems deliver increased productivity from initial scans to final inspection with approximately three-minute cycles at the highest resolution.

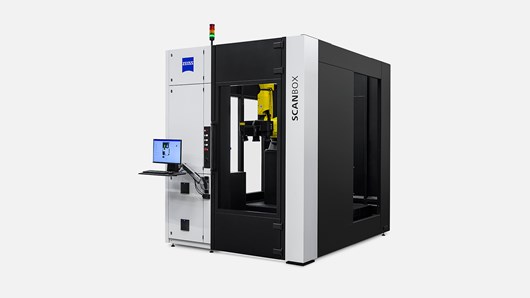

ATOS ScanBox BPS complements manufacturer needs by using automated technology to measure the hundreds of thousands of parts required each year, while GOM Inspect includes industry-leading measuring and inspection functionalities for airfoil geometries.

From casting measurements to airfoil coating thicknesses, this high-precision hardware and software combination is the production manager's and engineer's first choice for turbine blade measurement.

Repair and Overhaul

Turbine blades are built to last 35,000 hours before they need repairs or overhauls – this is roughly 15 million flight miles. However, when the time comes for repairs, it is one of the biggest cost factors OEMs face in terms of money and time. They need technology that helps uncover hidden errors, anticipate structural failures and quickly highlight imperfections to get the blades back into rotation and lengthen the lifetime of the turbine engine.

In addition to wear and tear analyses, ATOS technology supports the planning and control of repair jobs such as digital coordinate measurement of damaged/repaired surfaces and verification of material deposition. GOM customers use ATOS technology to close the performance analysis loop by creating a digital twin and verifying the condition of the blades for Computational Fluid Dynamics (CFD), stress and reliability. By providing detailed insights and predictions about turbine blade inspections, ATOS systems shorten downtime for repair jobs and maximize the lifespan of turbine blades.

Metrology Systems

Discover ATOS systems for every stage of turbine blade inspection