Aero Engine

Powered by Precision

More than 30,000 components form the engine of an aircraft. From design to operation, the smallest details matter as they have an immediate impact on safety, engine durability and fuel consumption. GOM's aero solutions meet the demands on the superlatives of the industry responding to highest complexity and speeding up product cycle times.

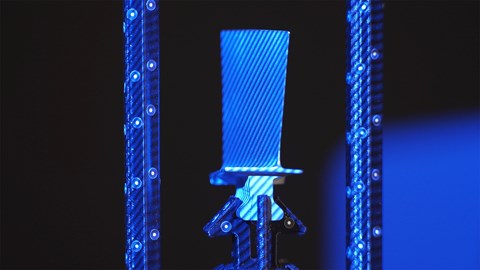

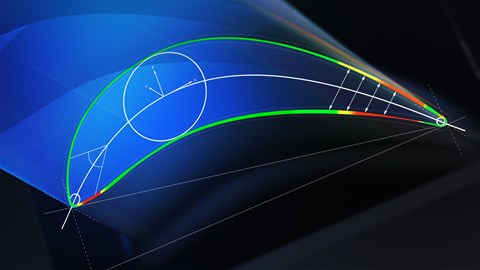

Fan Blade Inspection

Fan blade inspection is characterized by geometrical complexity and requires a highly advanced technological approach to meet functionality and material tests.

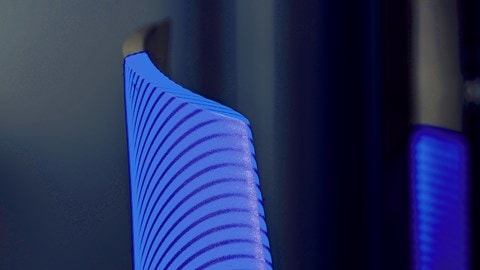

Compressor Blade Inspection

Compressor blade inspection needs precise measurement to fully evaluate the airfoil and root geometries for efficiency and performance.

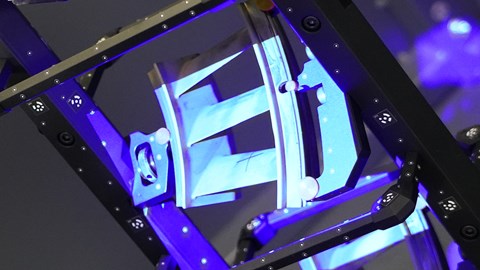

Blisk Inspection

Measurements on blisks require high-end automation processes for fast inspection results and sophisticated software to allow for in-depth analysis.MORE ›

Turbine Blade Inspection

Smallest details of turbine blades have an effect on the efficiency and fuel consumption of an aircraft. Speed and precision for inspection processes is key.MORE ›

Nozzle Guide Vanes Inspection

NGVs are crucial to engine performance and rely on robust measurement and inspection for features like throat area which are perfectly created from our digital twin.

Structural Casings Inspection

Every intricate geometry of a structural casing influences how air is directed during flight. Discover how GOM delivers an all-in-one system that meets the highest speed and accuracy possible.MORE ›

Achieving NADCAP Accreditation

Discover what it means to be NADCAP accredited and how GOM's ATOS systems can help you achieve accreditation and be a symbol of excellence and compliance.MORE ›

Inspect Blades with GOM Blade Inspect

GOM Blade Inspect offers specific inspections for the aerospace industry like quality control functions for the analysis of airfoils and turbine blades.

Single Airfoil Measurement and Inspection Training

Learn how to create your own ATOS ScanBox process for a single airfoil including acquisition, common and custom airfoil inspections as well as reporting.

MORE ›

Fan Blade Integrity Testing

Using the point tracking technology of ARAMIS, GOM carries out a study on a single fan blade to demonstrate its accuracy and speed on evaluating the integrity of aerospace components.MORE ›