- Automated solution

- ATOS ScanBox for fast and efficient inspection

Quality Assurance of Sheet Metal Parts

Quality Assurance of Sheet Metal Parts

Challenges:

Along with increasing requirements for functionality and safety, the demand for high-quality sheet metal parts grows continuously. Besides, a shorter time for the development and launch of products is a competitive factor. Therefore, a fast and efficient measuring machine checking the shapes and quality of the products is highly in need. However, tactile CMMs achieve a low throughput, leaving certain areas on the part unchecked.

Solutions:

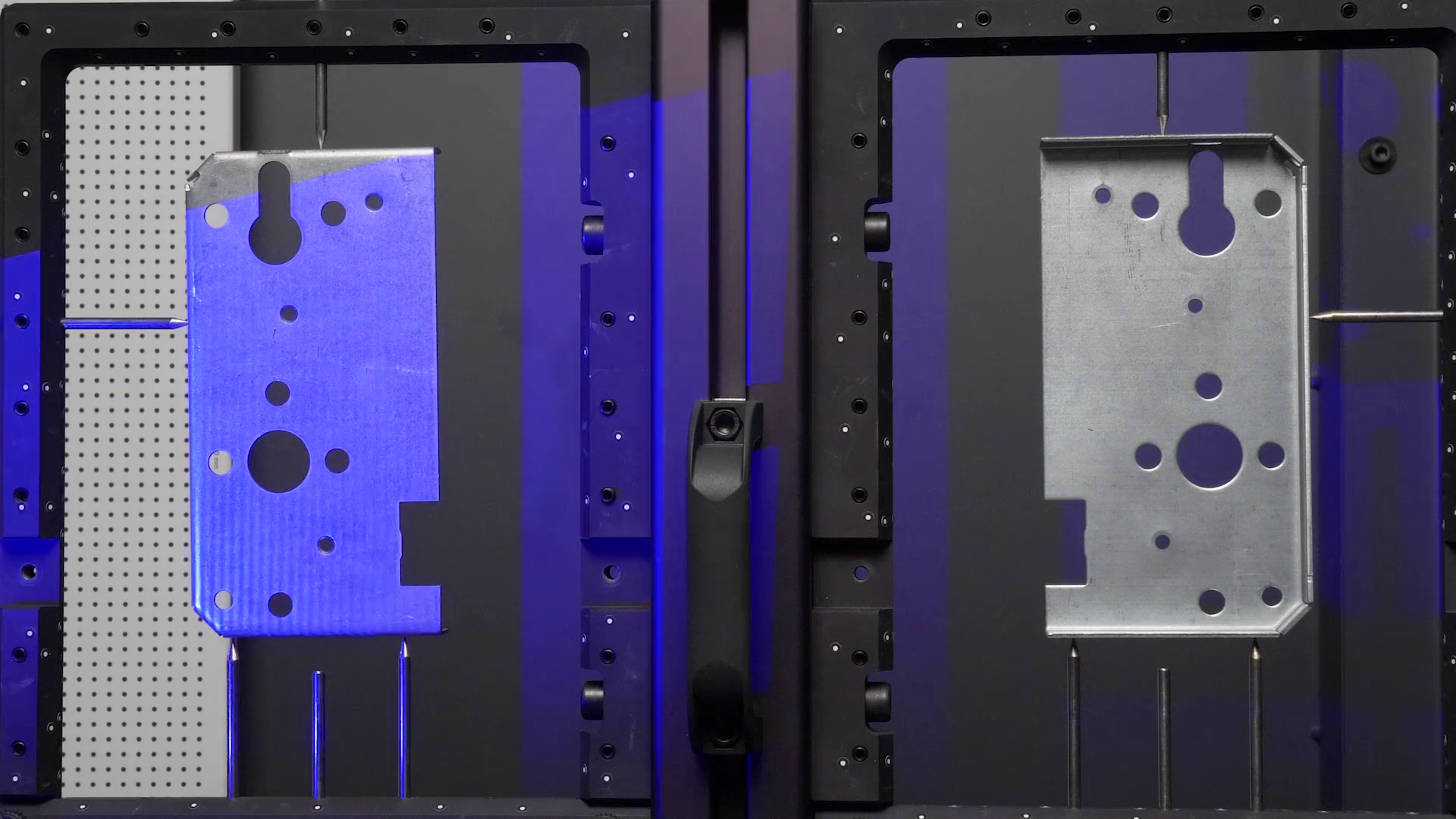

GOM’s automated solution, the ATOS ScanBox, allows a fast and efficient inspection of sheet metal parts. Its non-contact measuring system can be used in the sheet metal forming process to guarantee consistent quality assurance from tool try-out and first article inspection up to production control during series production and assembly analysis. The ATOS ScanBox is delivered with the virtual measuring room (VMR) in the GOM software for easy measurement planning and control. After the setup in the VMR, the ATOS ScanBox runs the measurement and inspection program automatically. Even reflecting sheet metal parts and sharp-edged features, such as laser trimming and hole patterns, can be measured precisely. The measurement results give an immediate feedback on the quality of the parts. Users can see the overall shape distortion and look at the trim deviation. The parametric GOM Inspect software even supports multi-part scanning and trend analyses of many parts during production.

Benefits:

- Easy handling

- Virtual measuring room for complete measuring procedure

- High data quality

- Thanks to Triple Scan Technology and Blue Light Technology