Process-integrated quality assurance in metal forming

Process-integrated quality assurance in metal forming

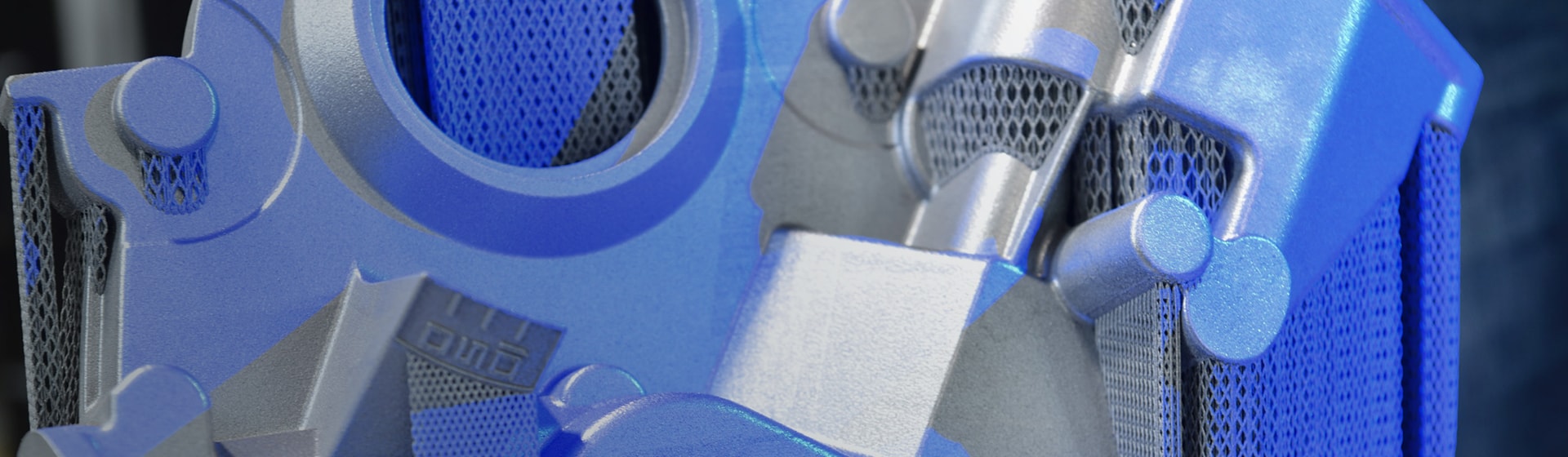

Get the best out of optical 3D metrology: From manual measurements with GOM’s high-speed 3D scanning system ATOS 5 to automated solutions for series inspection in ATOS ScanBox 6235.

Topics

- Fast and precise: Learn how to increase the quality of your parts by creating and using a digital twin for process and quality control.

- See what challenges must be overcome in the production of battery trays - live demo included.

- For beginners and experts in the field of optical 3D metrology.

Getting started with optical 3D metrology: Manual and automated standard solutions

On March 23, 2021, we present you the basics of precise industrial 3D metrology in metal forming: from manual measuring systems to automated solutions for series inspection. Our experts demonstrate which systems are used for efficient part inspection and can be operated by a worker.

Knowledge in practice: Automated 3D metrology in the production process

In this expert webinar, on March 24, 2021, we introduce you to the advantages of the optical 3D measuring machine ATOS ScanBox. We demonstrate how to use optical 3D metrology to generate highly accurate and traceable data.