主页

ScanBox 树立工业三维计量新标准

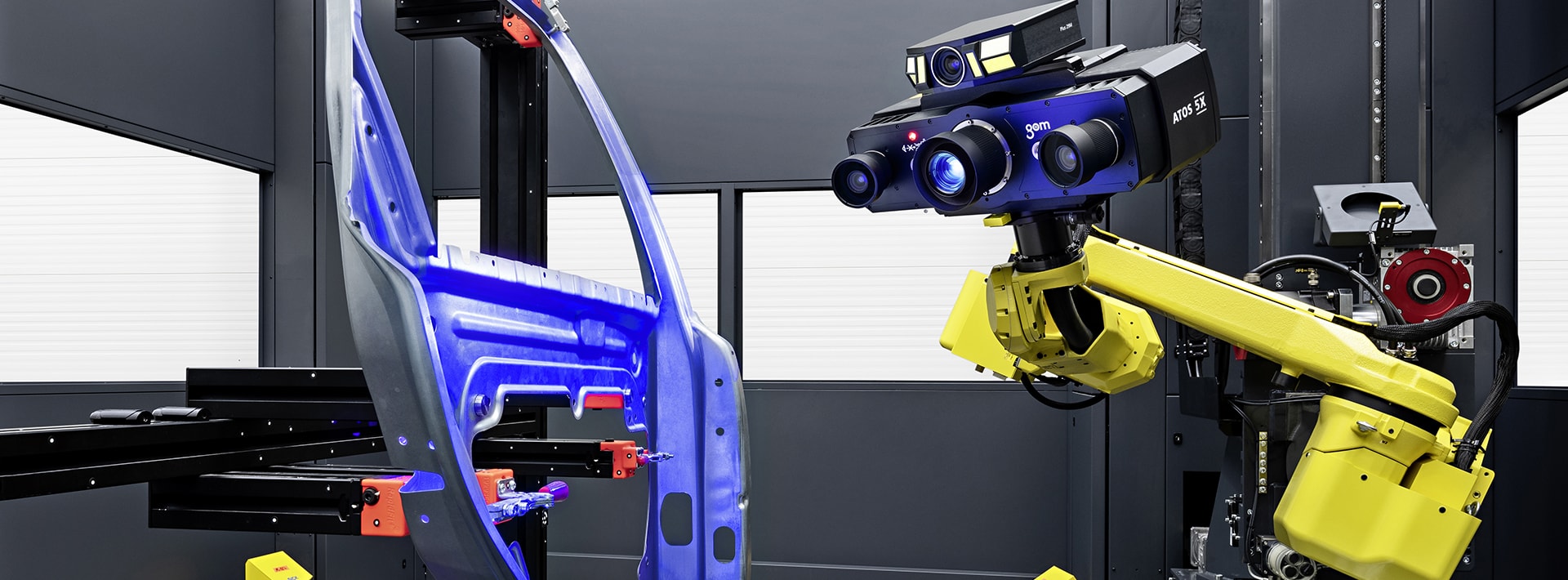

ScanBox是一种光学测量系统,可为客户提供快速精确的测量数据,用于生产和制造过程中的质量控制。该系列系统有11种型号,可提供准确、可追溯的测量结果,确保高产量。用户界面设计简单直观,以虚拟计量室(VMR)作为中央控制和测量计划软件,易于操作。

我们专注创新

塑造品质

三重扫描技术,ATOS ScanBox,GOM Inspect软件——GOM代表技术创新和对卓越品质的孜孜追求。公司推崇可持续发展和家庭友好制度。

对我们的环境负责

GOM的环保意识不仅体现在公司办公楼内的能源利用上,餐厅也使用可重复使用的物品,以抵消一次性包装消费的增长。

创造一个具有吸引力的工作环境

在我们所处的地区,GOM被评为最佳雇佣企业。如今GOM还成为了公认的家庭友好型雇佣企业。弹性的工作时间和儿童保育补贴帮助员工平衡工作和家庭生活。