ZEISS INSPECT Airfoil

GOM Blade Inspect is now ZEISS INSPECT Airfoil

As of the release 2023 we have united our software products under the same roof and the same name: ZEISS INSPECT.

Learn more about the renaming here.

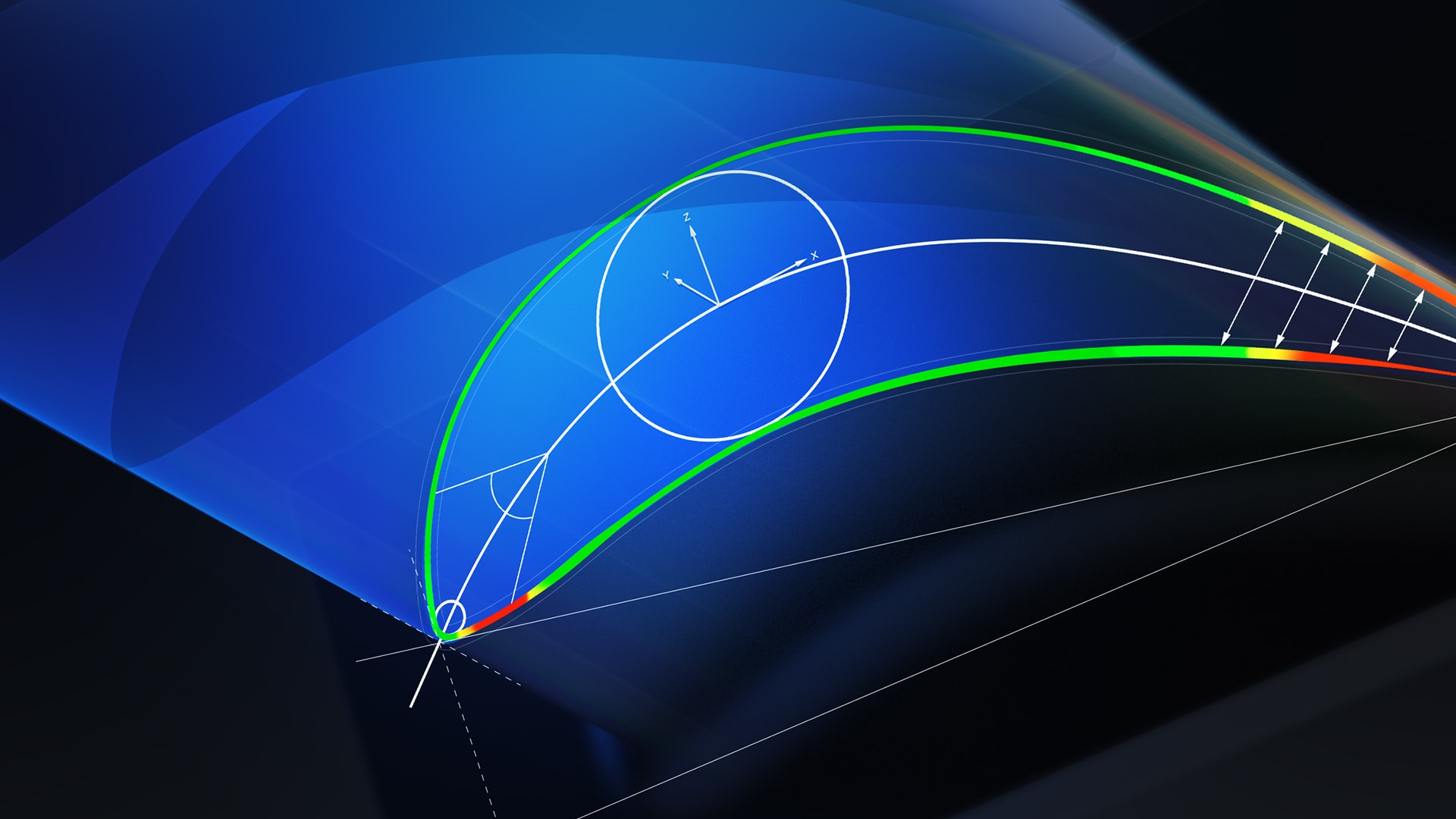

One thing has not changed: ZEISS INSPECT Airfoil remains the software for the simple and efficient analysis of blade geometries. Regardless of whether it is an aircraft or gas turbine – safety is the defining issue. That’s why quality assurance is especially important. It does not matter whether your data comes from tactile or optical measurement systems – ZEISS INSPECT Airfoil is designed to be system-independent.

In the course of the renaming, our contents have moved to zeiss.com.

Do you know the ZEISS Quality Suite?

Benefit from our digital ecosystem:

- Seamless workflows in one place

- Services such as eLearnings, online help and the latest metrology news

- Always up to date with updates