ZEISS INSPECT Optical 3D

GOM Inspect is now ZEISS INSPECT Optical 3D

As of the release 2023, we have united our software products under the same roof and the same name: ZEISS INSPECT. Learn more about the renaming here.

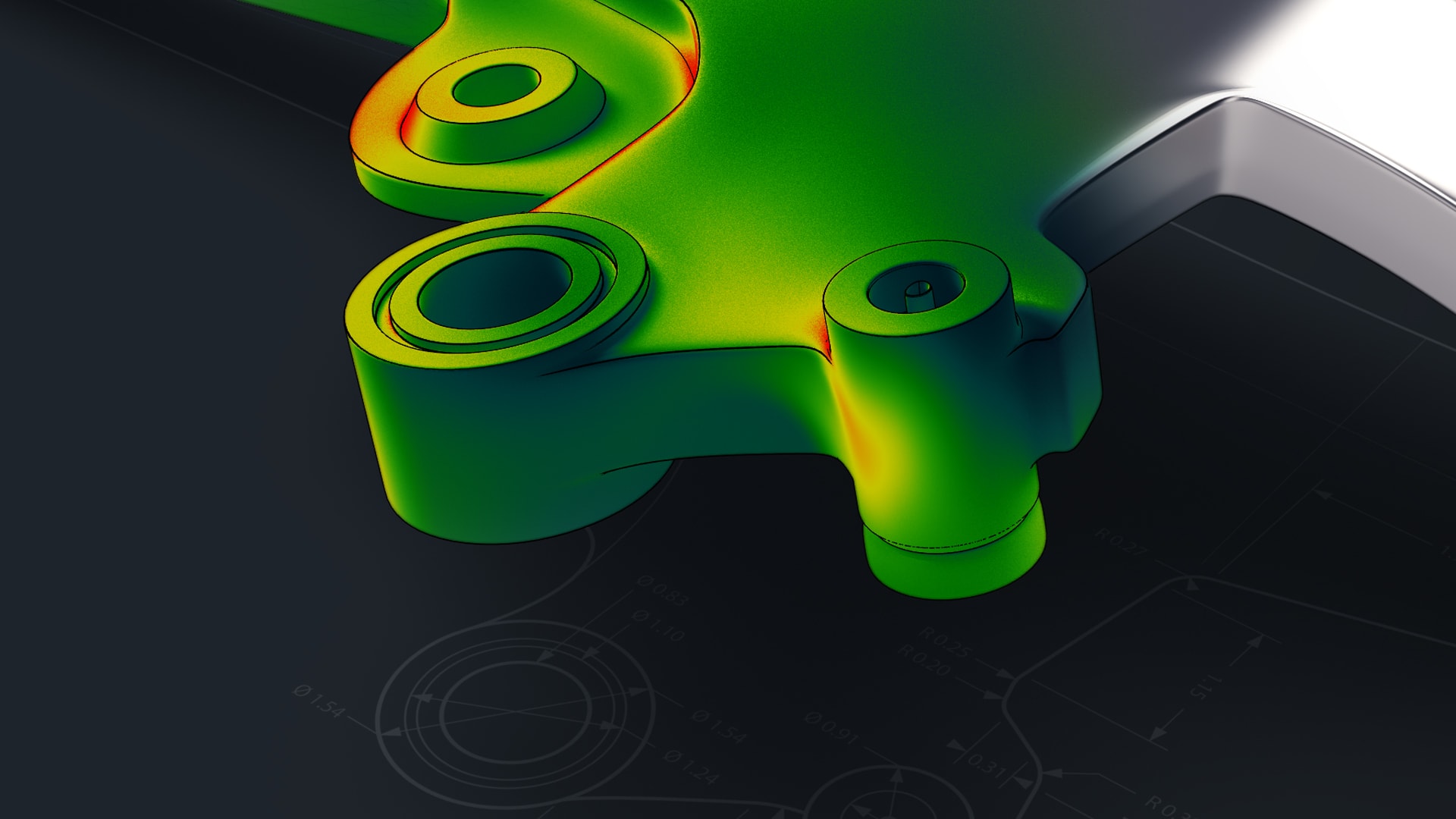

One thing will not change: ZEISS INSPECT Optical 3D is still the industry standard when it comes to the evaluation of optically measured 3D surface data. Use the software for simple or complex inspection tasks - from GD&T calculations to trend analyses, and digital assembly – no matter which optical measurement system you use to acquire your data. ZEISS INSPECT Optical 3D is designed to be system-independent.

In the course of the renaming, our contents have moved to zeiss.com.

Do you know the ZEISS Quality Suite?

Benefit from our digital ecosystem:

- Seamless workflows in one place

- Services such as eLearnings, online help and the latest metrology news

- Always up to date with updates