3D Testing

3D Testing

Measure deformations in real time

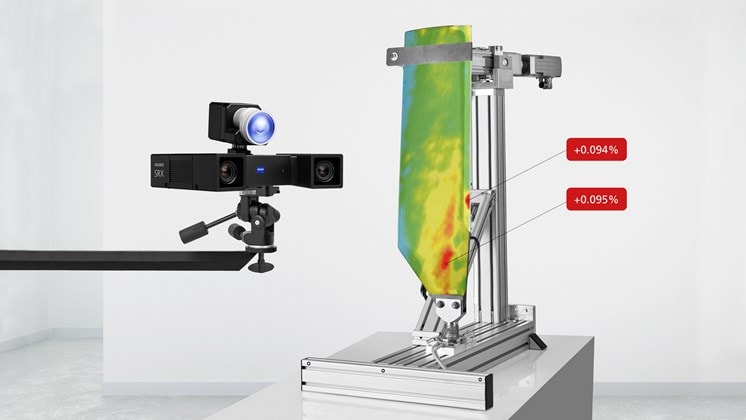

The ARAMIS product portfolio comprises sensors for dynamic measurements of 3D coordinates, 3D displacements and 3D surface strain. Based on triangulation, the systems provide precise 3D coordinates for full-field and point-based measurements.

Optical 3D Motion and Strain Analysis

Ideally suited for product development, materials research and component testing

The analyses provide information on material characteristics and the behavior of components under load. These results form the basis for product durability, geometrical layout, reliable numerical simulations and their validation.

Fast and easy test procedure

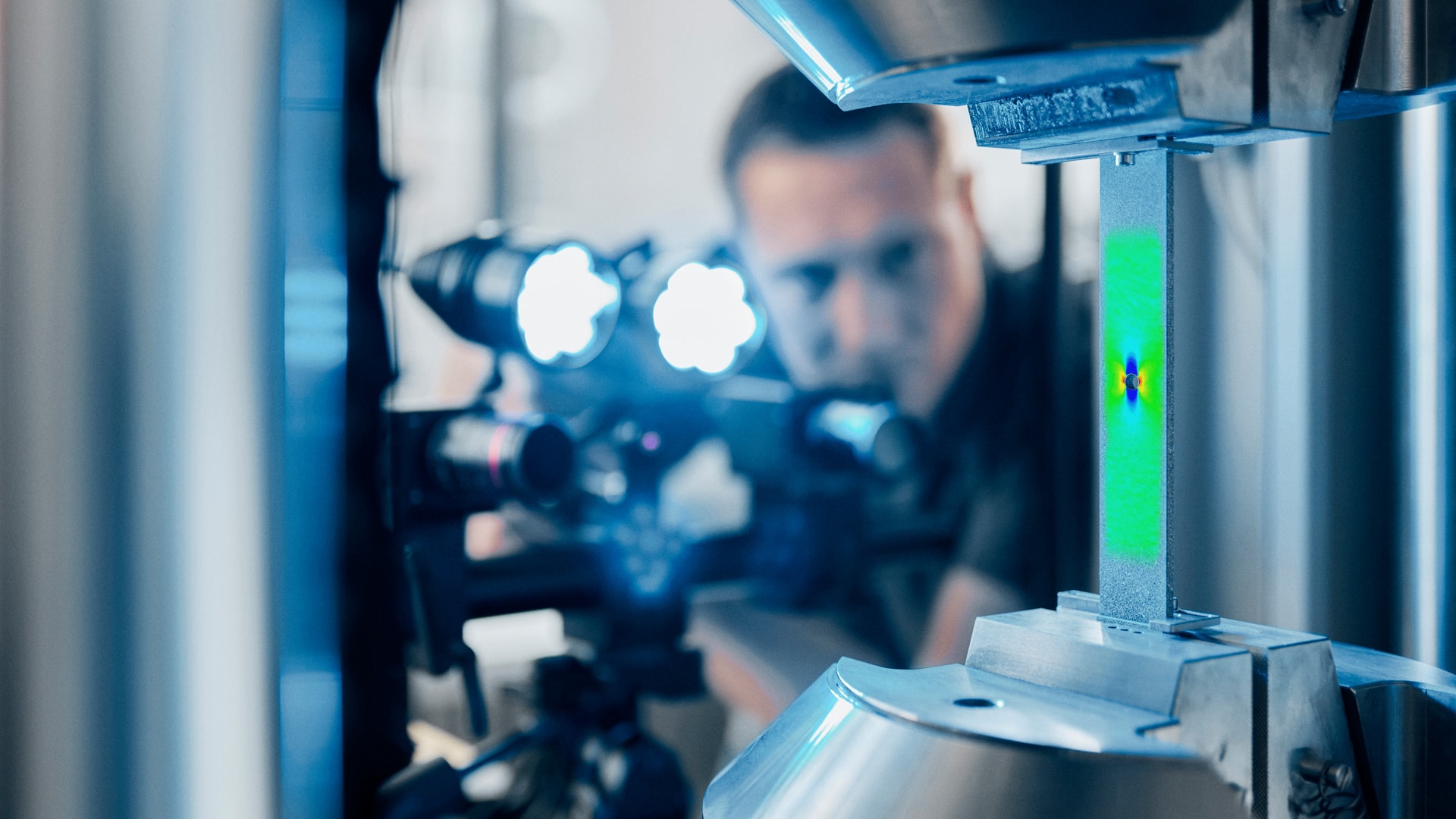

ARAMIS sensors measure statically or dynamically loaded specimens and parts by using a contact-free and material-independent method based on the principle of digital image correlation (DIC) – without time-consuming and expensive preparations of the test object.

High-precision measurements of small and large objects

The system offers stable solutions for the analysis of specimens of just a few millimeters up to structural components of several meters. The measuring resolution reaches down to the submicrometer range independent of the geometry and temperature of the specimen.

Metrology Story

Dresden University of Technology

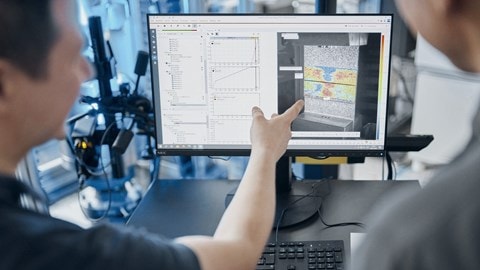

Analysis of physical effect chains

At the Vehicle Testing Centre (FVZ) of the TU Dresden ARAMIS SRX sensors are used to carry out dynamic analyses on complete vehicles in the test bench. Emphasis is given to evaluating the interaction of the parts chassis, axles and tires.

Overview of ARAMIS Sensor Concepts

ARAMIS for Testing Applications

Integration into the testing environment

The associated ARAMIS Controller can be used for easy programming of user-defined measuring sequences, offers image-synchronous signal recording of external measurement signals (e.g., force), transmits analog and digital measurement values and provides numerous options for integrating the system into the testing environment.

Multisensor

Combining several ARAMIS sensors allows for measurements from various perspectives with different measuring areas. The measurements are captured and evaluated in one common coordinate system at the same time.

Large measuring volume

Also for dynamic measuring of complex or large applications, ARAMIS makes it possible to evaluate, for example, the vibration behavior of individual blades of wind power plants under heavy load.

Long-term online measurement

Online component testing is used, for example, in durability tests, fatigue tests as well as in wind tunnel tests and vibration analyses. The measuring results can be viewed online or processed live by other programs.

ARAMIS Kiosk Interface – automated check

ARAMIS Kiosk Interface is a user interface for automated evaluation of tensile tests complying with different standards. With minimized user interaction, standardized testing procedures can be carried out fast, easily and repeatable for measurement series with numerous specimens.

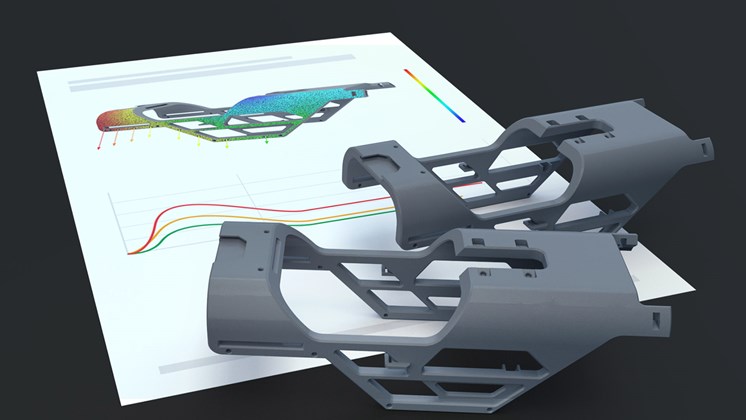

Verification of numerical simulation

ARAMIS sensors provide information on material properties of parts. This data is used as input parameters for simulation computations and as reference size for optimization and verification. The ZEISS software allows importing FE data from formats including ABAQUS, LS-DYNA and ANSYS as well as aligning them to the measuring data and in space.

ARAMIS Generates Precise Data

- 3D displacements

- 3D deformations

- Velocities and accelerations

- Surface strain

- Digital image correlation (DIC)

- Material properties for simulation

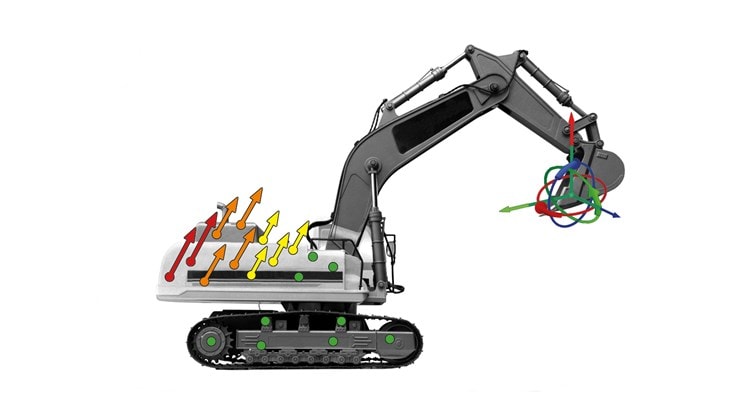

- Evaluation of 6 degrees of freedom (6DoF)

- 3D coordinates

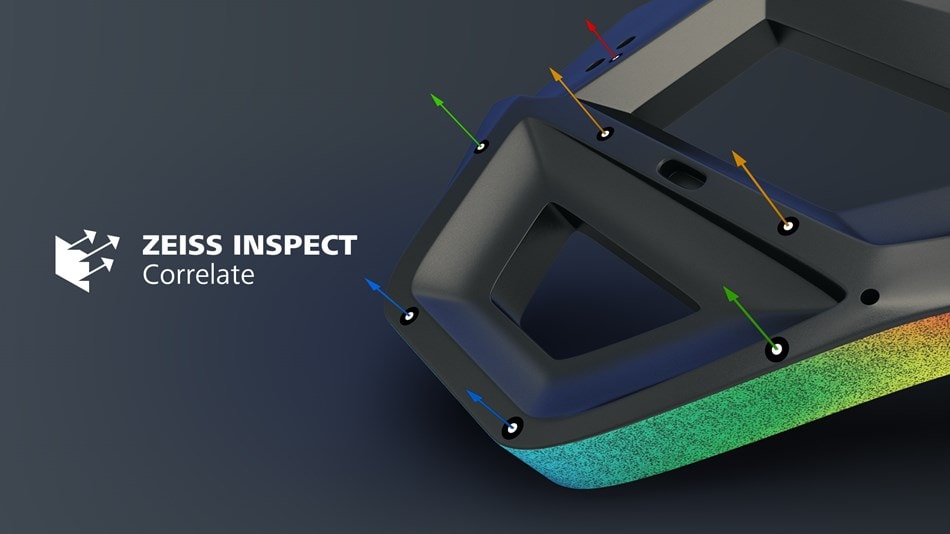

ZEISS INSPECT Correlate Software – Digital Image Correlation

The ZEISS INSPECT Correlate software provides the complete workflow from measuring data acquisition via analysis up to reporting. It combines the synchronized acquisition of images and analog data of the ARAMIS sensors with the evaluation functionality of the ZEISS INSPECT Correlate software.

ARAMIS offers solutions for numerous application areas

Industries

Automotive

In e-mobility, lightweight construction or classic disciplines of vehicle development: With 3D measuring data from ARAMIS, OEMs and service providers can reliably meet the stringent requirements regarding safety, function and service life.

Aerospace

In the aerospace sector, ARAMIS has established itself as an indispensable measuring solution for characterizing all kinds of materials and for analyzing the reaction of prototypes, components and structures to mechanical loads.

Electronics

ARAMIS provides the competitive advantage that companies need in this fast-paced industry: more efficiency in product development combined with essential expert knowledge regarding materials and parts.

Medical Technology

Optical 3D metrology provides valuable insights for research on new materials and the development of orthopedic implants and sports products.

Power & Energy

The energy sector is facing a huge transformation in the course of the expansion of renewable energies. Energy-producing companies must always keep the safety of their plants in mind. In order to ensure safety, a large number of mechanical tests such as tensile, compressive and bending tests are carried out. In addition, vibration tests on components such as generators and turbines play an important role in ensuring that the components can withstand the high loads caused by vibrations during operation. ZEISS ARAMIS is the optical measurement solution for the determination of strains, deformations and displacements in 3D.

Fields of application

Materials characterization

Precise, full-field ARAMIS measuring results improve the accuracy of material characteristics. Existing evaluation procedures are optimized and become more reliable, such as the determination of flow curves and forming limit curves. Some material tests can only be performed due to the non-contact method of ARAMIS measurements and the high local resolution of the results. This is applied to tensile, shear, compression and 3-point bending tests as well as to high-speed and temperature tests.

Prototype testing

ARAMIS is used for strength and vibration analyses, fatigue limit and crash tests. The measuring results form the basis for determining product durability and load limits and for optimizing the geometrical layout. During load testing, the system measures the real part geometry along with the non-linear deformation behavior and allows for direct comparison with FEM data.

Validating numerical simulations

ARAMIS sensors provide information on material properties, the deformation behavior of parts and the boundary conditions of test setups. The measurement data are used as input parameters for simulation computations and for optimization and validation of FEA models. The software allows for importing FE data from ABAQUS, PAMSTAMP, LS-DYNA and ANSYS, AUTOFORM as well as for aligning them in 3D to the measuring data and in space.

Optical Solution for Forming Analysis

Services

GOM keeps supporting its customers after the purchase and installation of 3D measuring systems.